1.1 Development of a product

Suppliers are encouraged to work closely with packaging suppliers and customers in developing new products.

Suppliers are encouraged to work closely with suppliers of packaging and customers in the process of developing new products.

The grocery industry is heavily packaging intensive. Increasing demands and expectations from authorities and consumers for reduction in use of virgin fossil materials and replacing plastic, whenever possible, will be highly focused. “Design for recycling” will be crucial to meet future regulations, expectations, environmental requirements and recycling goals.

Reduction of food waste will have increased focus to meet reduction targets agreed by the trade and the Norwegian authorities.

The grocery value chain in Norway has for many years exercised responsibility by active ownership in the material return shemes for packaginxg Grønt Punkt Norge and by funding the company Matvett to prevent food waste. These organizations are available to support you introducing more sustainable products.

Areas affected by, and subject to guidelines from STAND are:

- Optimization and requirements for design of Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU) with accompanying packaging materials

- The modular system

- Case fill rate

- The top load labelling system

- Automatic warehouse at distributor – increased understanding of depalletization process

- Checklist

- Valid pallets and requirements for these

- Labelling requirements

- Guidelines for how to label Consumer Unit (CU) with 2D barcode

- Purpose of labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU)

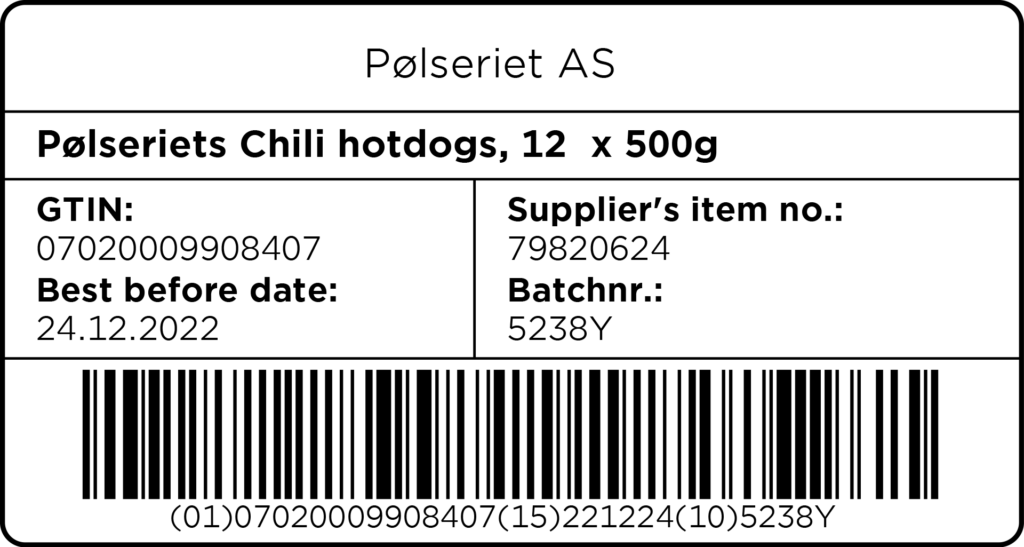

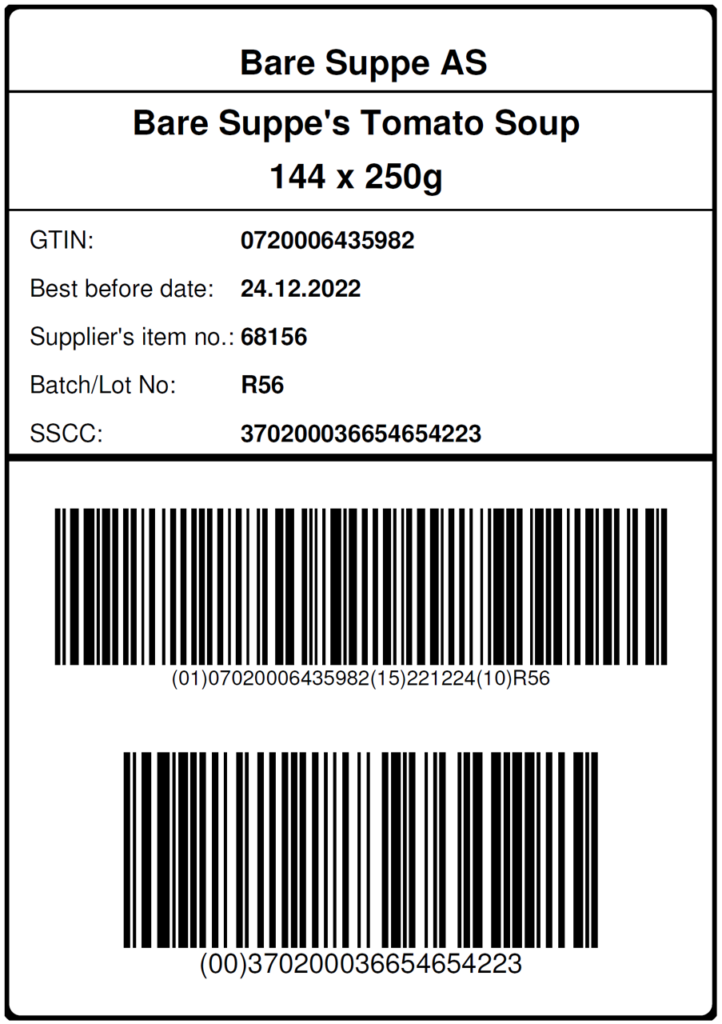

- Product information on Stock Keeping Unit (SKU), with example of Stock Keeping Unit (SKU) label

- Guidelines for labelling of Stock Keeping Units (SKU)

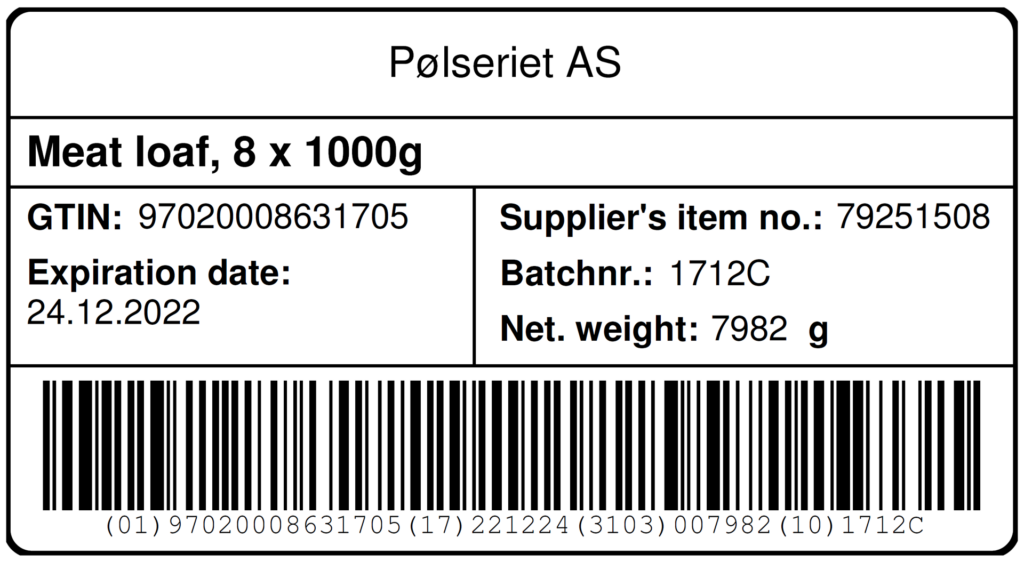

- Product information on Distribution Unit (DU), with example of Distribution Unit (DU) label

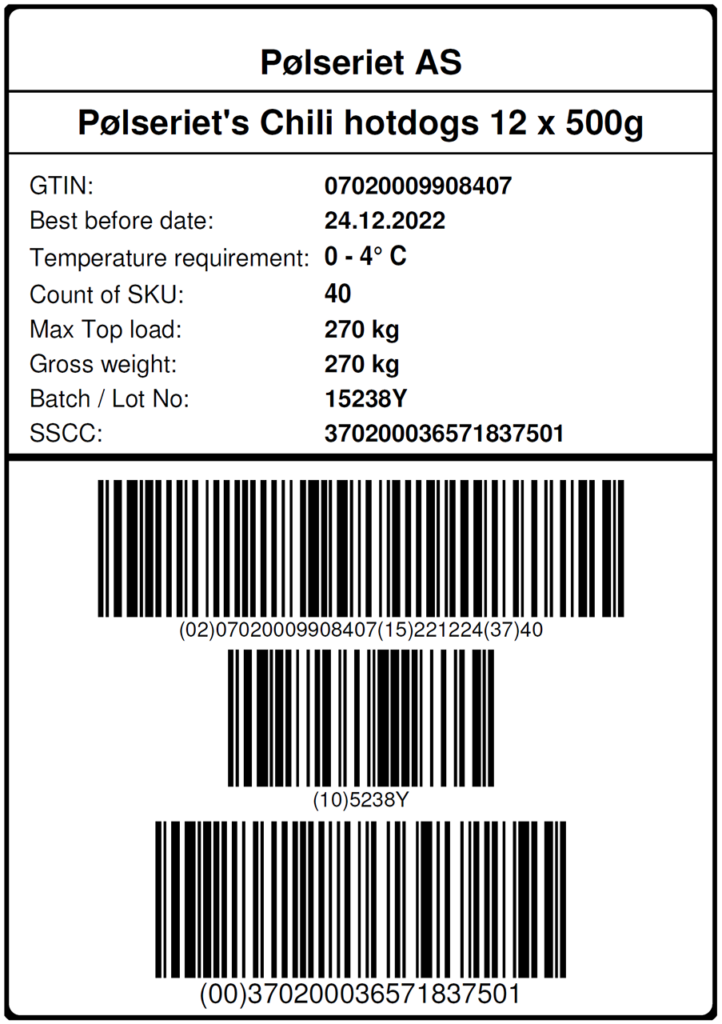

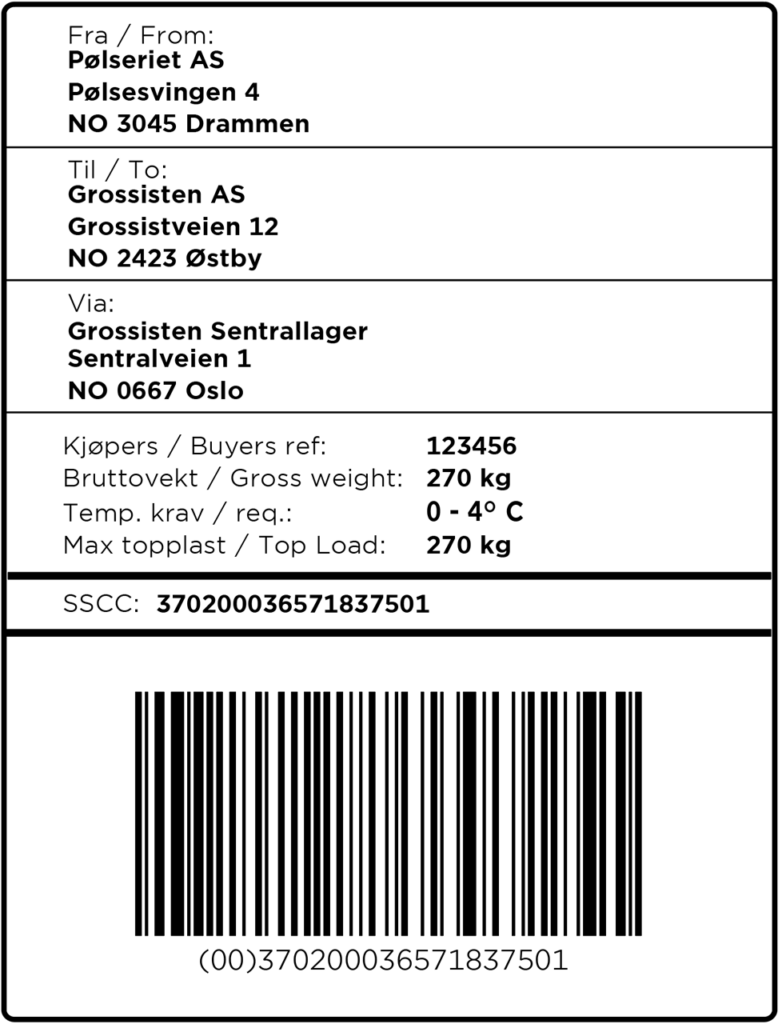

- Labelling of transport information

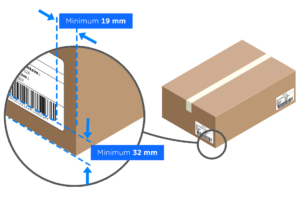

- Guidelines for labels on Distribution Units (DU)

- Bar code requirements for labelling with GS1-128 on Distribution Unit (DU)

- Shelf life

- Determine total shelf life of a product and labelling requirements

- Allocation of shelf life between the players in the value chain

- Use of dynamic shelf life

- Bilateral agreements for allocation of shelf life

- Traceability of a product

- Guidelines for traceability, recall and withdrawal

- Requirements for traceability of products and the product areas covered by this

- Requirements for traceability information and labelling

- Alternative ways to track and trace an item in the value chain

Endringslogg

1.1.1 Optimization of Consumer Unit (CU), Stock Keeping Unit (SKU), Distribution Unit (DU) and packaging – central to the development of new/changes to existing products

The grocery industry has a common goal of being able to:

- Streamline product flow

- Reduce environmental impact

- Promote sales

- Reduce shrinkage

when products are being developed/changed.

To achieve this, it is crucial to standardize and optimize packaging on the product at all packaging levels – Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU).

STAND has therefore prepared a standard for this, which applies to all packaging levels.

Audience for the standard is managers and everyone who works with product development, assortment and logistics in the value chain.

By complying with the standard, processes in the value chain are optimized and gains can be extracted in a number of areas such as:

Warehouse

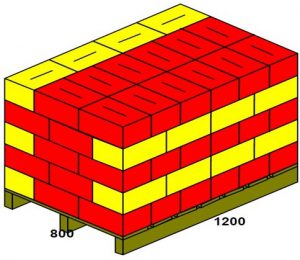

- Form Stable Distribution Units (DU) and Stock Keeping Units (SKU)

- Correct quality of Distribution Units (DU) and Stock Keeping Units (SKU) for efficient handling through warehouse

Outbound transport

- Withstand double stacking

- Avoids shrinkage and damage

Inbound transport

- High case fill rate

- Double stacking of pallets

- Avoiding transport damage

Shop

- Effective replenishment

- Sales-friendly, good visibility when Stock Keeping Unit (SKU) is used to expose products

- Optimal use of shelf space

- Reduced food waste, with correct number of Consumer Units (CU) in Stock Keeping Unit (SKU)

- Reduced food waste, utilising 2D barcodes with dynamic information

Consumer

- Optimal and user-friendly packaging

- Clear, accurate and complementary product declaration

- Recycling labelling

- Extended product information utilising 2D barcodes

In addition, optimization of packaging through compliance with the standard will reduce environmental impact at all stages in the value chain, as part of the industry agreement with the authorities.

The packaging must be:

Easy to sort

In order for the packaging to be able to be recycled, it is important that it is sorted correctly by the end user and thus enters the correct recycling stream. There are a number of steps you can take when designing the packaging, which increase the likelihood that it will be sorted correctly. This information is summarized at https://www.grontpunkt.no/design-for-kildesortering

Recyclable

In order for the packaging to be material-recycled and become new raw material that can be used to make new products, it is important that this is taken into account in the packaging design and material selection. To find out how recyclable the packaging is and what steps can be taken to improve this, you can enter the packaging in https://kalkulator.grontpunkt.no

In monomaterial if possible

The easiest way to make it more intuitive for the end user to sort the packaging correctly, and to make it easier to recycle the packaging, is to ensure that the packaging only consists of one material.

From recycled material if possible

Most packaging is recycled, but there is too little demand for recycled material. By using recycled material when developing new packaging, you ensure that the circular material flows work and thus both reduce the need for virgin raw material and the environmental burdens these entail.

Important notice

All products must follow the GS1 Allocation rules. (chapter 2.4). These are international rules and are mainly based on the fact that a change of over 20% to a physical dimension, on any axis, or gross weight, requires assignment of a new GTIN.

In addition, the following applies to Norway:

- For products registered in the Tradesolution EPD base, approval of the grocery chains is required to keep existing GTIN on a product, also for changes below 20%

- Frequent cumulative changes, without changing the GTIN, in avoidance of the 20% rule is an unacceptable practice. Trading partners should be notified about all dimensional changes. Cumulative changes might cause problems for trading partners and may obstruct the transport and supply of a product

- Local, national or regional regulations may require more frequent GTIN changes. Such regulations have precedence over the rules provided within the GTIN Management Standard

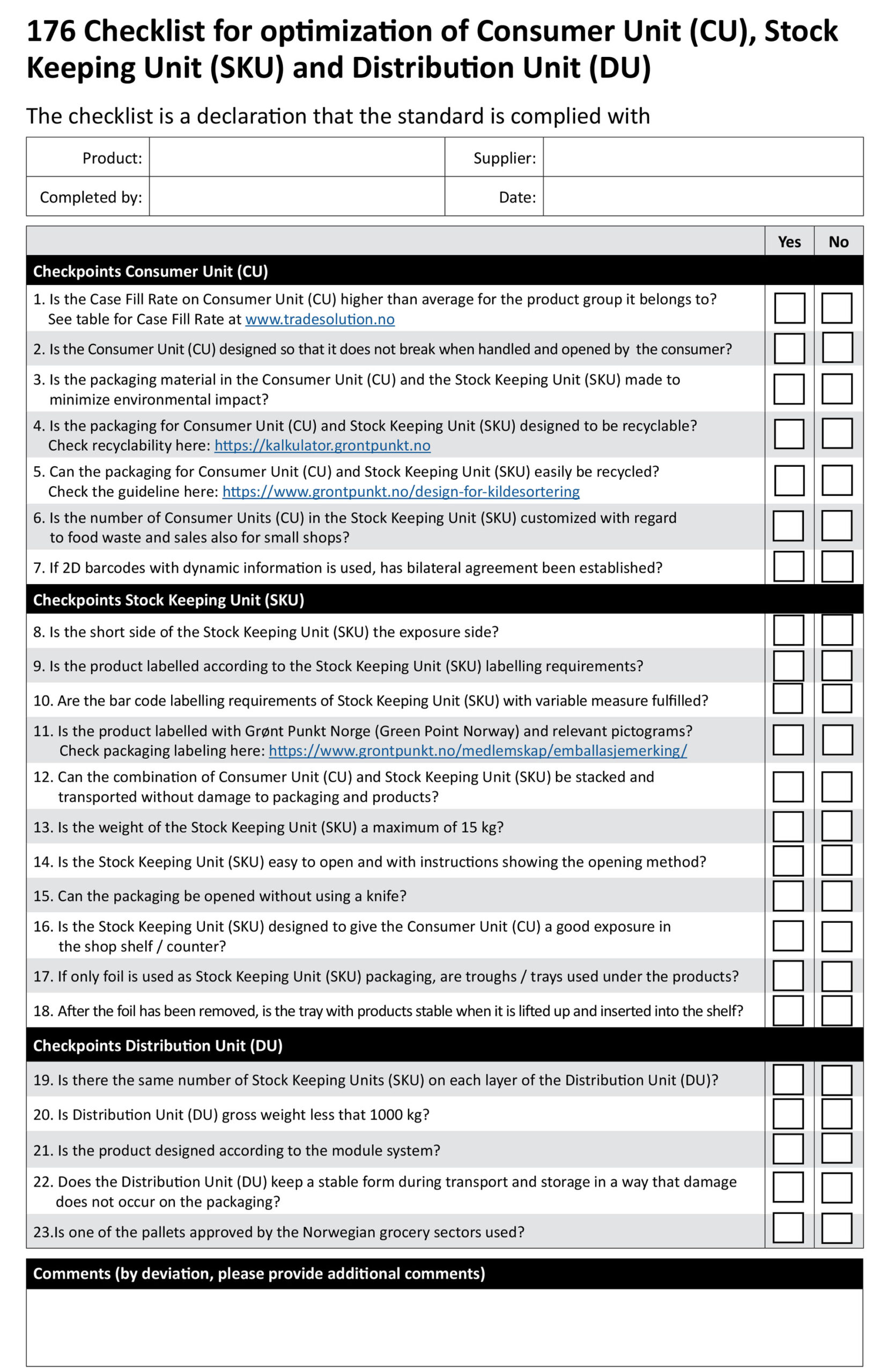

Exception from the standard

Under special conditions, exceptions from industry standards and guidelines may be relevant.

Exceptions must be agreed separately between the parties concerned and shall be described in Checklist for optimization of Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU).

The check list can be downloaded as a separate document.

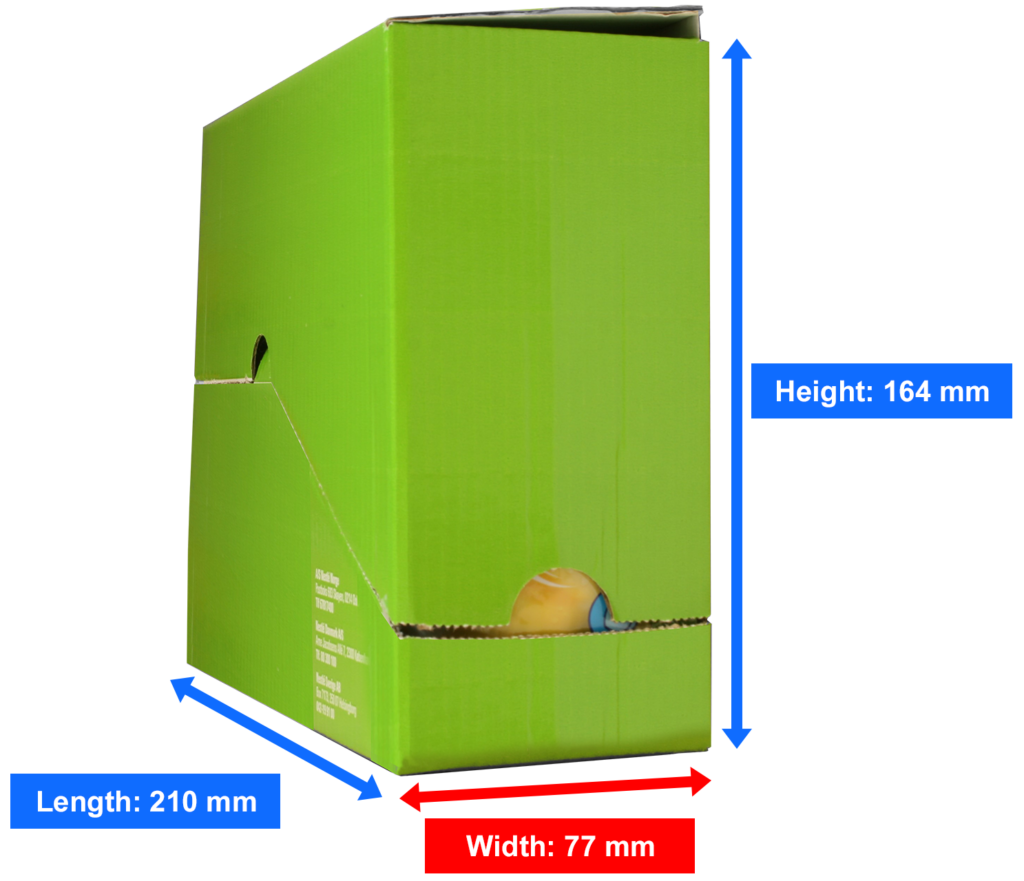

1.1.2 Requirements for design of Consumer Unit (CU)

Consumer Unit (CU) is the unit the consumer purchases in store.

Consumer Unit (CU) must be designed to optimize use of shop shelves and other furnishings. In addition, the information on the Consumer Unit (CU) should be visible even when the package is on a tray on the shelf.

Consumer Unit (CU) should be easy to open and to use.

Consumer Unit (CU) should be, included Stock Keeping Unit (SKU) and Distribution Unit (DU) adapted to the modular system, see Modular system

Unnecessary volume not containing the product itself in the packaging should be limited to what is necessary to protect the product. If necessary, secure against shrinkage (small, valuable Consumer Units (CU)).

Quantity (packing content) in Consumer Unit (CU) is determined by manufacturer, preferably in dialogue with distributor / retail chain.

Case fill rate shall be calculated. This is described in Case fill rate

On new products, it is expected that the case fill rate is higher than the average of the product group to which it belongs.

Measurement of the case fill rate related to the product launch windows was carried out by DMF until 2018. When switching to a new product classification system, historical data could not be compared, as the timeline and product groupings from 2014 were changed.

Efforts to increase the case fill rate in the grocery industry are important from both an environmental and efficiency perspective.

In collaboration with the industry, Tradesolution has developed some new reports for measuring the case fill rate in the grocery industry. Suppliers and retailer chains that have access to the EPD base can see the case fill rate for the products they have access to directly in the database. Here you can see the actual case fill rate on basic product (BASIS-level) and calculated case fill rate for the packaging levels above.

Log in her and feel free to contact the EPD base helpdesk at epd@tradesolution.no if you have further questions.

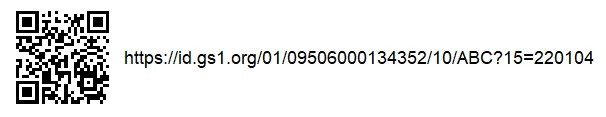

1.1.3 Guideline for labelling 2D barcodes on Consumer Units

Background

The need for information both in trade and to the consumer is constantly increasing. Today’s solution using the EAN-13 barcode does not provide opportunities for additional machine-readable information. The need for more information has led to products that have more than one bar code applied to Consumer Units, which creates challenges both at the checkout point (POS) and in the value chain. Often this is a QR code with a link to a website where the consumer can find more information.

In parallel with the need for more communication with consumers, a need is emerging at the retail level to gain more control over the traceability and expiry date of the products, to ensure safe food and reduce food waste. This is happening in most countries in the world. In Norway, GS1 Norway, together with Matvett, established a working group consisting of representatives from brand suppliers, grocery chains, system suppliers and other stakeholders to discuss these issues. These guidelines are a result of this work and have now been included as part of STAND’s framework for the Norwegian grocery industry.

Purpose of the use of 2D barcodes in Norwegian grocery

Although 2D barcodes are not the only solution to the challenges, this is the data carrier of the future, where the need for information is greater than just identifying a product with GTIN. 2D barcodes take up less space, can contain more information about the product, are a tool for reducing food waste and increase food security, are more flexible, and can be read by mobile phones. This provides an opportunity for increased consumer contact. In addition, 2D barcodes can solve all needs for information exchange throughout the supply chain, including being able to link to websites.

Different types of 2D barcodes

There are many different 2D barcodes, but only some of them can be used in connection with the GS1 standards, which are the standards used by the Norwegian grocery industry. The different 2D barcodes are also used for different purposes. This is regulated in GS1’s regulations, General Specifications. The difference between the different 2D barcodes helps to determine what they can be used for.

QR Code

The QR Code barcode is in the GS1 system defined to be used only with GS1 Digital Link URI syntax. In practice, this means that this should only be used for communication with the consumer via a URL that links to a website with more information that the consumer can read with his mobile phone. QR Code has grown to become the preferred barcode for consumer communication and most mobile phones today are able to read this with the built-in camera app in the phone. This means that the threshold for reading QR Code is low among consumers, and it is less need for training and communication to put functionality related to QR Code into production. Here you can find more information about QR codes.

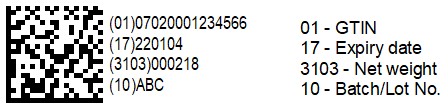

GS1 Datamatrix

GS1 Datamatrix is a variant of Datamatrix that uses GS1 Element String syntax. This is the use of AI (Application Identifier) structure. This is a way of structuring the information in the barcode so that everyone who reads the barcode understands the content in the same way regardless of the order in which the information is printed and how much information is in the barcode. According to GS1 General Specifications, GS1 Datamatrix is only permitted for use on Consumer units with variable measure and prescription medicines. However, it is permitted to use it in limited pilots, for test purposes and in closed value chains under controlled conditions. The advantage of GS1 Datamatrix is that it has high compression and error correction. It can be printed both square and rectangular so that it can fit where there is not enough height, but enough width to get the information needed without compromising on size and thus readability. However, the rectangular version has a limit on the amount of data that can be used. GS1 Datamatrix is the only permitted barcode on prescription drugs. Here you can find more information about GS1 Datamatrix.

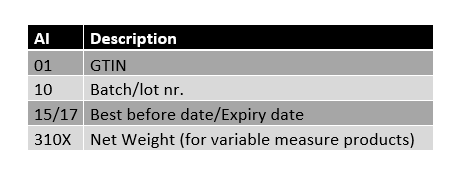

Content in barcode

A minimum requirement for information attributes has been defined for POS purposes.

This is:

- GTIN

- Best before date or Expiry date

- Batch/lot nr.

- Weight (for variable measure products).

It is possible to use other Application Identifiers for internal and/or external needs, but this is then up to each individual actor to use.

Checklist for optimization of Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU)

The checklist is a declaration that the standard is complied with

Endringslogg

Innhold

- 1.1.1 Optimization of Consumer Unit (CU), Stock Keeping Unit (SKU), Distribution Unit (DU) and packaging – central to the development of new/changes to existing products

- 1.1.2 Requirements for design of Consumer Unit (CU)

- 1.1.3 Guideline for labelling 2D barcodes on Consumer Units

- 1.1.4 Requirements for design of Stock Keeping Unit (SKU) and packaging

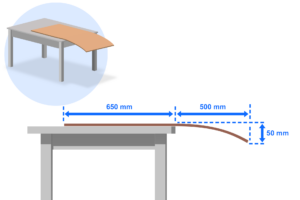

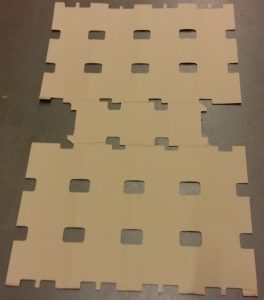

- 1.1.5 Requirements for the design of the Distribution Unit (DU) and palletization

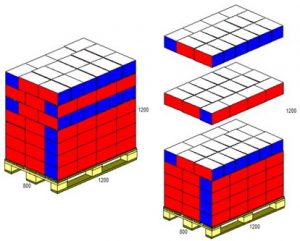

- 1.1.6 Placement of Stock Keeping Unit (SKU) on pallet

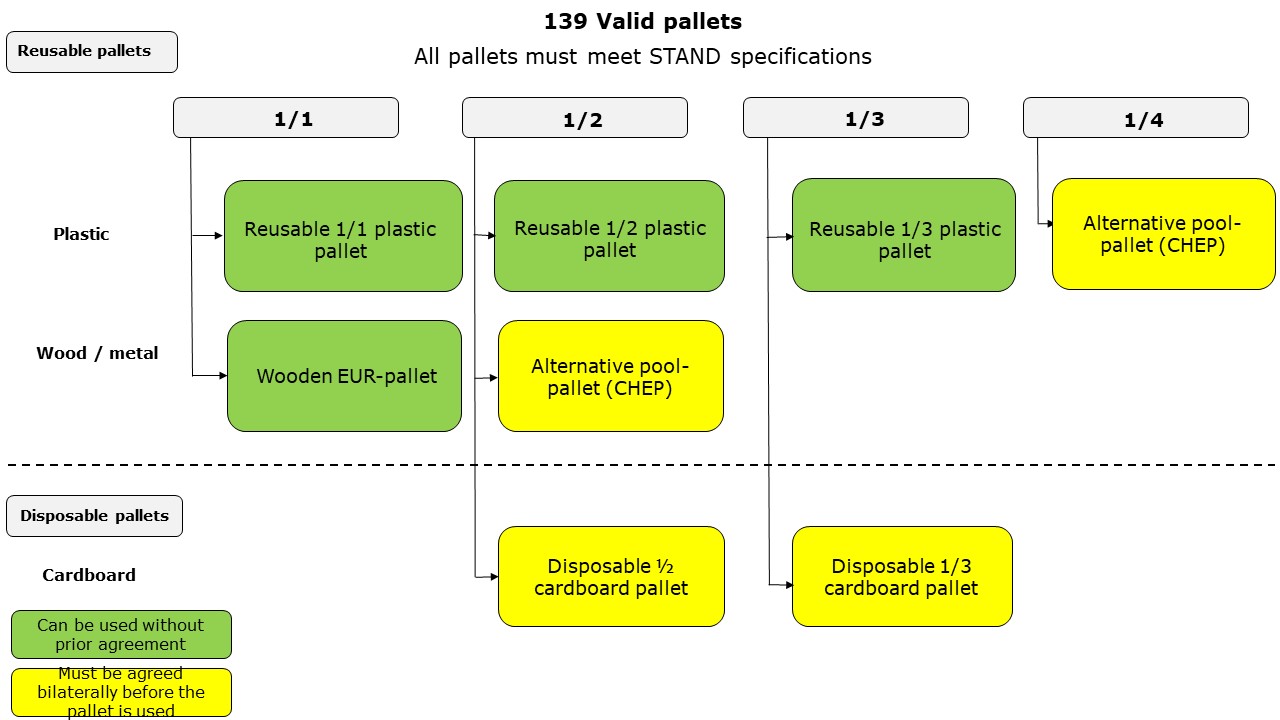

- 1.1.7 Valid pallets

- 1.1.8 Purpose of labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU)

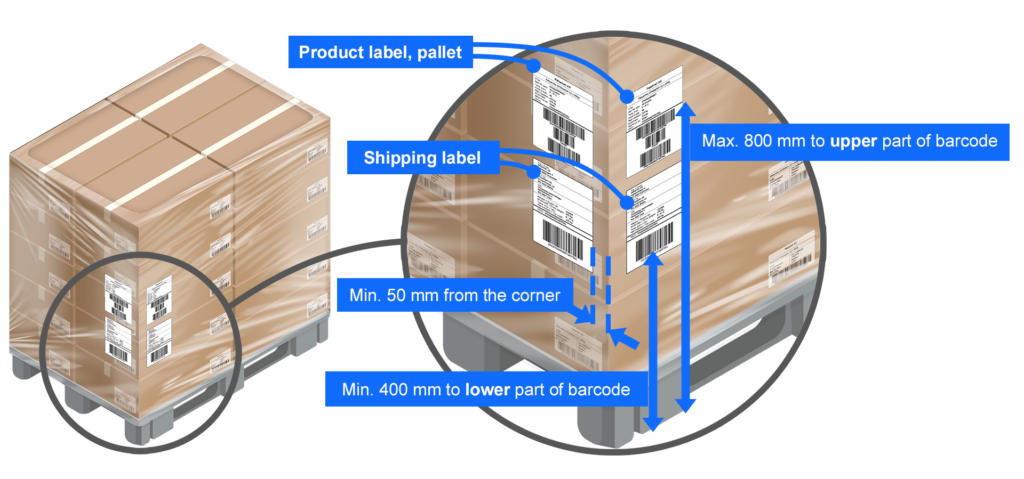

- 1.1.9 Guidelines for labelling of Stock Keeping Units (SKU)

- 1.1.10 Product information on Distribution Unit (DU), with example of Distribution Unit (DU) label

- 1.1.11 Transport information on pallet with example of transport label

- 1.1.12 Guidelines for labels on Distribution Units (DU)

- 1.1.13 Bar code requirements for labelling with GS1-128 on Distribution Units (DU)

- 1.1.14 Determine total shelf life of a product and requirements for labelling this

- 1.1.15 Allocation of total shelf life on a product

- 1.1.16 Evaluate the use of dynamic shelf life

- 1.1.17 The establishment of bilateral agreements for the assessment of shelf life

- 1.1.18 Guidelines and routines for tracking, recall and withdrawal

- 1.1.19 Routines covered by the guidelines

- 1.1.20 Prepare a Risk Analysis

- 1.1.21 Prepare a Contingency Plan

- 1.1.22 Product tracking requirements

- 1.1.23 Requirements for tracking information and labeling