Goods reception

This sub process describes the requirements, recommendations and guidelines STAND applies to receiving a delivery.

It does not describe internal procedures, but focuses on controls that shall and can be done upon receipt of the delivery. The check includes both Distributions Units (DU) and the individual Stock Keeping Unit (SKU).

In addition, the sub process describes some of the traceability and main points of any recall or withdrawal, as products receipt may have an active role in any eventual events.

Finally, measurements of service levels are described and how this can be used as an effective tool for establishing a common platform as a basis for measurement, communication and mutual evaluation of performance.

The areas described are:

- Transfer of responsibility for a product at Ex Works delivery terms

- In general, what controls should be performed on products receipt at Ex Works delivery terms

- Valid pallets and requirements for these

- Assessments related to shelf life

- Assessment of total shelf life on a product with an allocation table

- Execute customer order related to product shelf life

- The establishment of bilateral agreements for the assessment of shelf life

- Complaints according to Ex Works delivery terms

- Guidelines for return of products

- Labelling requirements

- Purpose of labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU)

- Product information on Stock Keeping Unit (SKU), with example of Stock Keeping Unit (SKU) label

- Guidelines for labelling of Stock Keeping Units (SKU)

- Product information on Distribution Unit (DU), with example of Distribution Unit (DU) label

- Labelling of transport information

- Guidelines for labels on Distribution Units (DU)

- Bar code requirements for labelling with GS1-128 on Distribution Unit (DU)

- Packaging / palletization

- Requirements for the design of Stock Keeping Units (SKU) and packaging, with the modular system, case fill rate and top load labelling system, as well as special requirements for products and pallets in order for this to work in the distributor’s automated warehouse

- Requirements for the design of the Distribution Unit (DU) and palletization

- Traceability of delivery

- Guidelines for traceability, recall and withdrawal

- Requirements for traceability of products and the product areas covered by this

- Requirements for traceability information and labelling

- Alternative ways to track and trace a product in the value chain

- Implementation of actions when an event occurs

- Measurement of service levels, with definitions on target measures and examples of how these are calculated

Transfer of responsibility for products at Ex Works delivery terms

The responsibility for the products is transferred when the seller has made the product available for the buyer in accordance with the agreement.

Unless otherwise agreed, the buyer is responsible for loading of products.

The buyer is liable for any risk of loss or damage to the products from the time the products is placed at the buyer’s disposal.

Check of products at loading, receipt at warehouse, and retailer at Ex Works delivery terms

The buyer or the party acting on behalf of the buyer shall, when the responsibility for the products has been transferred, control the quantity and possible damage to a reasonable extent.

- When loading:

- The number of load carriers and external damage is checked, and whether an exchange or reusable pallet is used.

- Reception at distributor’s warehouse:

- Number of load carriers, external damage, correct product, and if used

exchange or reusable pallet.

Date labelling and number of Stock Keeping Units (SKU) are checked when placed on a stall or pick-up place.

- Number of load carriers, external damage, correct product, and if used

- Reception in store:

- Damage that could not have been discovered when receiving the delivery at the distributor’s warehouse.

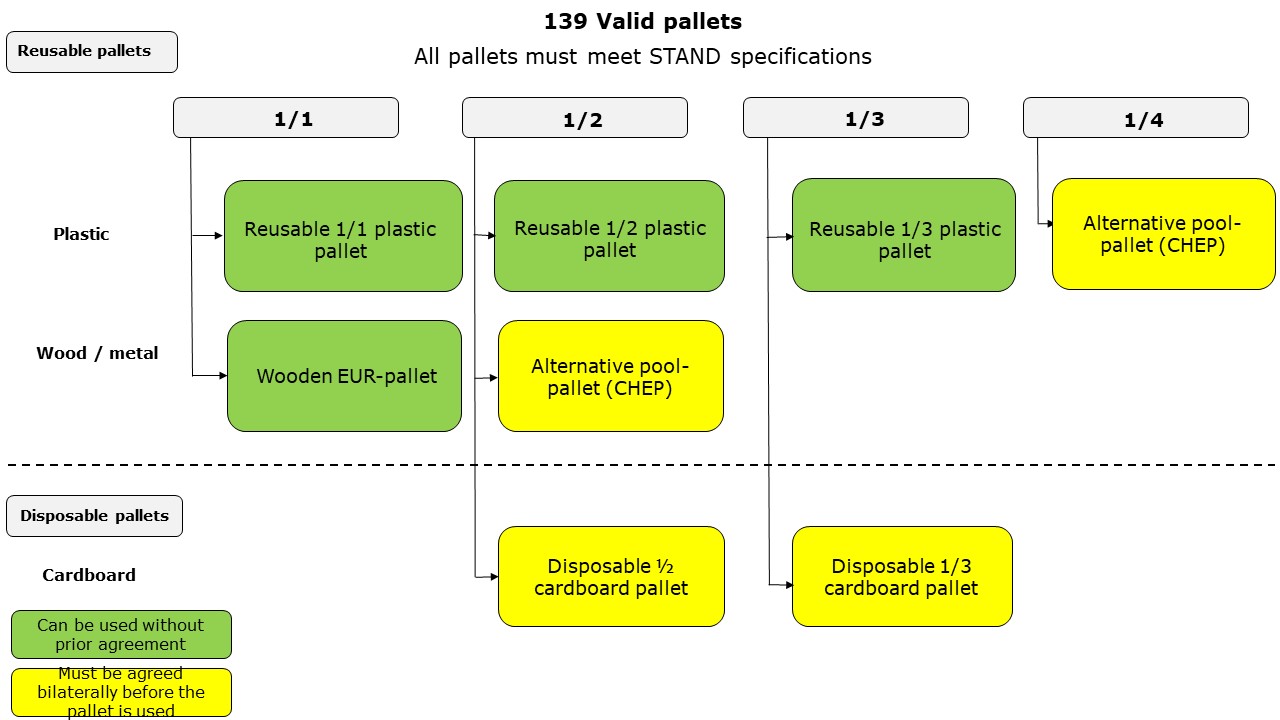

Valid pallets

This is an animation that show what pallets are valid for distribution.

Requirements specifications can be downloaded here:

Requirements for approved EUR-pallets

Specification for reusable 1/1 plastic pallet

Specification for reusable 1/2 plastic pallet

Requirements specification for reusable 1/3 plastic pallet (from NLP)

Specification for reusable 1/4 plastic pallet

Requirements Specification reusable 1/2 wooden pallet

Requirements specification for 1/3 and 1/2 disposable cardboard pallet

Allocation of total shelf life on a product

Reducing food waste is an overall goal in society. Food waste related to exceeding the limit values of shelf life between the parties in the value chain, constitutes a significant part.

Surveys shows that food waste are significantly reduced if the store and the consumer have a larger part of the total shelf life.

It is therefore a goal that the producer and distributor consume the least amount of available time and that the maximum amount of time is exposed to the consumer.

The grocery industry has defined one Table for allocation of shelf life of a product which regulates the responsibility for and expectations the recipient of products has, linked to shelf life. Online players with b2c sales will be defined as retailers when dividing total shelf life.

In case of minor exceedances of the table’s limit values, participants are expected to seek solutions that provide the lowest possible food waste.

The parties are encouraged to develop performance and collaborate to reduce consumption of shelf life.

Endringslogg

The establishment of bilateral agreements for the assessment of shelf life

The risk of food waste is related to the remaining shelf life of a product. To avoid food waste, the players in the grocery industry have agreed to exhibit flexibility in the value chain to handle minor deviations in assessment of shelf life. This is done by establish bilateral agreements.

Bilateral agreements will contribute to more flexible assessment of shelf life, thereby reducing food waste in the value chain (manufacturers, distributors, retailers), considering specific and specific conditions, such as geographical distance to customer / market, and volume of sales.

The grocery industry has defined a table for the assessment of total shelf life, based on a three-division between manufacturer, distributor and retailer / consumer. The table prepared for this applies unless otherwise agreed bilaterally.

For products with short shelf life (42 days or less), conditions such as distance to the market and volume of sales will be decisive for determining optimal assessment of shelf life.

- For products with shelf life between 17 and 42 days it is encouraged to consider establish bilateral agreements

- For products with shelf life below 17 days there shall be established bilateral agreements

How to establish bilateral agreements

The assessment of shelf life as stated in the table is the basis for the bilateral agreements.

All parties can initiate bilateral agreements based on expected potential for reduction of total food waste.

Description of how the risk will be shared should be included in the agreements.

Measuring consumed shelf life in the value chain is an instrument for securing facts and monitoring development.

Some examples of situations where it may be appropriate to establish bilateral agreements:

- Deviant date from the table

One example of reducing waste for products with short shelf life is that a supplier in the eastern part of Norway establish a bilateral agreement with a customer regarding a better date than is stated in the table for deliveries to, for example, northern part of Norway, while for example a customer in the middle and western part of Norway receives deliveries according to the table and with the possibility of deviating dates for smaller volumes for deliveries to the southern and eastern part of Norway.

- Divergence date in the beginning of the week

Products delivered at the beginning of a week is quickly reaching the distributor / distribution centre and the retailer before the weekend and is less prone to simple date deviations. Similarly, it is less appropriate to deliver products with “last day according to STAND” or with date deviations on Fridays, if they will not be received by distributor / distribution centre before Sunday evening / Monday.

- Deviant date for promotions

In advance of a promotional period, a delivery agreement with a few day date deviations may be applicable, as these products will have higher turnover than usual for the distributor / distribution centre and at retailers. To reduce the risk of increased drop by lower turnover than usual at the distributor / distribution centre and at retailer at the end of the promotional period, a better date should be provided than indicated in the table.

- Product / value chain specific assessments

Depending on the product / value chain, it may be advisable to redistribute days. For example:

Product with uneven turnover at retailers and / or a lot of waste at retailers.

Here it may be advisable to redefine days from supplier and / or distributor to retail days.

Product with steady turnover at retailers and / or a small amount of food waste.

Here it may be advisable to redefine days from retail and / or distributor to supplier.

Dispatch of customer orders related to product shelf life

Transport time and delivery frequency should, if possible, be criteria that are taken into account in cases where there is different shelf life on products available at time of shipment.

«Fresher products» are delivered to distributors or customers with long distances of transport / low frequency of delivery.

Complaints by Ex Works delivery terms

The buyer shall make a complaint about errors or defects in the products within a reasonable time after the error or defect is discovered or should have been discovered.

Seller who claims that the complaint deadline has been exceeded must do so immediately after the complaint has been received.

The buyer may require replacement, redeployment, price reduction, etc. pursuant to the provisions of the applicable law (Kjøpsloven).

All errors and defects must be based on the things that the seller is responsible for.

Guidelines for return of products

Return of saleable, undamaged products is usually not accepted.

However, the parties may make agreements for return of products for example in connection with:

- Replacement of old product upon introduction of a new product

- Seasonal products

- Campaigns initiated by the seller

- Returns must always be agreed in advance.

Purpose of labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU)

The purpose of a standard for labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU) with subsequent electronic data interchange (EDI) is to:

- Achieve an efficient flow of products from manufacturer to consumer

- Ensure traceability through the value chain, which is important in case an event or crisis occurs which requires a recall or withdrawal of the product

The basis for this is the labelling of each Distribution Unit (DU) with a unique SSCC.

This code is the main key in the electronic Despatch Advice and is linked to information about which GTIN which the Distribution Unit (DU) consists of, the number of Stock Keeping Units (SKU) batch / lot number and shelf life information if applicable.

SSCC is the most important key for traceability of Distributions Units (DU), see Recommended way to track and trace a product in the value chain.

For that reason SSCC shall not be reused until after a minimum of 6 years.

Recommended way to track and trace a product in the value chain

Efficiency and traceability are achieved primarily through:

- Synchronization of product information between the various parts in the value chain.

The purpose is for all players to obtain correct and coherent product information about the products. Between suppliers and retail chains in the Norwegian groceries sector the EPD database is used for the registration, quality assurance and distribution of product information.

- Electronic Data Interchange (EDI) between the actors.

The purpose is to reduce manual operations and reduce lead time in the value chain. The most widely used EDI messages are order, order confirmation, Despatch Advice and invoice.

- Standardized labelling of outer packaging.

The purpose is to contribute to faster and more efficient shipping, distribution and receipt of the products. A common labelling concept for the grocery industry is used here; GS1-128.

To ensure rational product and information flow in the distribution chain, STAND recommends a uniform labelling of Stock Keeping Units (SKU) and Distribution Units (DU).

This simplifies the labelling of the manufacturer / supplier, shipment by shipper / freight forwarders and merchandise at distributor / store.

This labelling concept also applies to types of transport units other than pallets.

For fish and fish products, the following applies:

STAND has decided to refer to Norwegian Standard NS17099:2020 “Information technology — Fishery and aquaculture products — Requirements for labelling of distribution units and pallets in the trade of fishery and aquaculture products” for products that fall under this category. This standard replaces todays NS9405: 2014 “Fish and fish products. Requirements for labelling of distribution units and pallets in the trade of fish and fish products», and is valid as from 30. September 2020.

It can be ordered from Standard Norway.

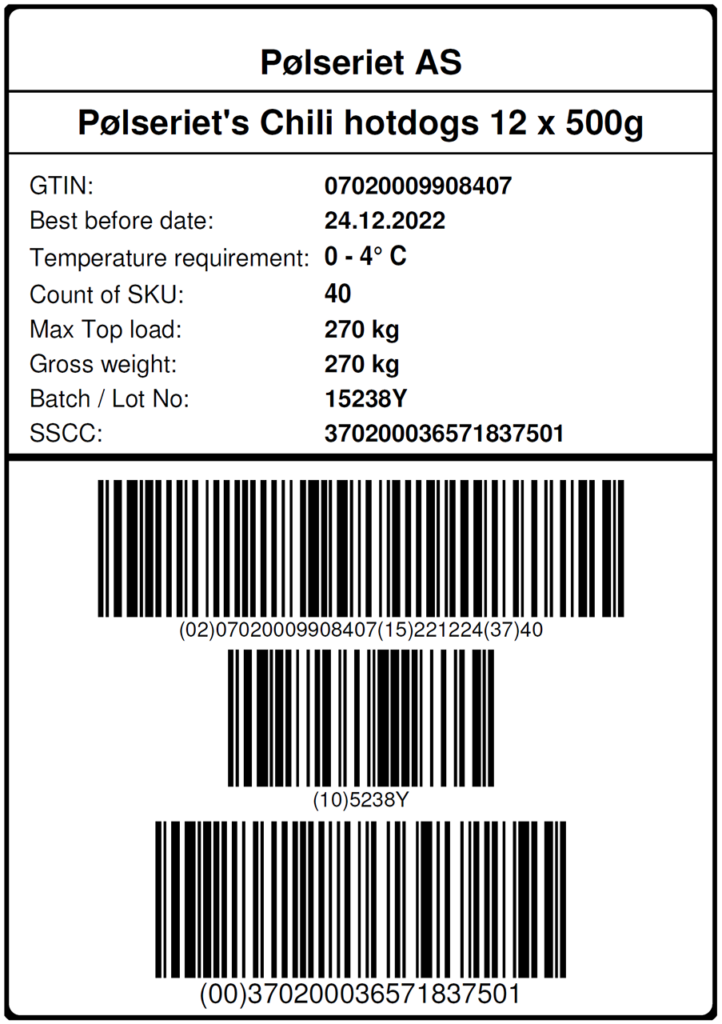

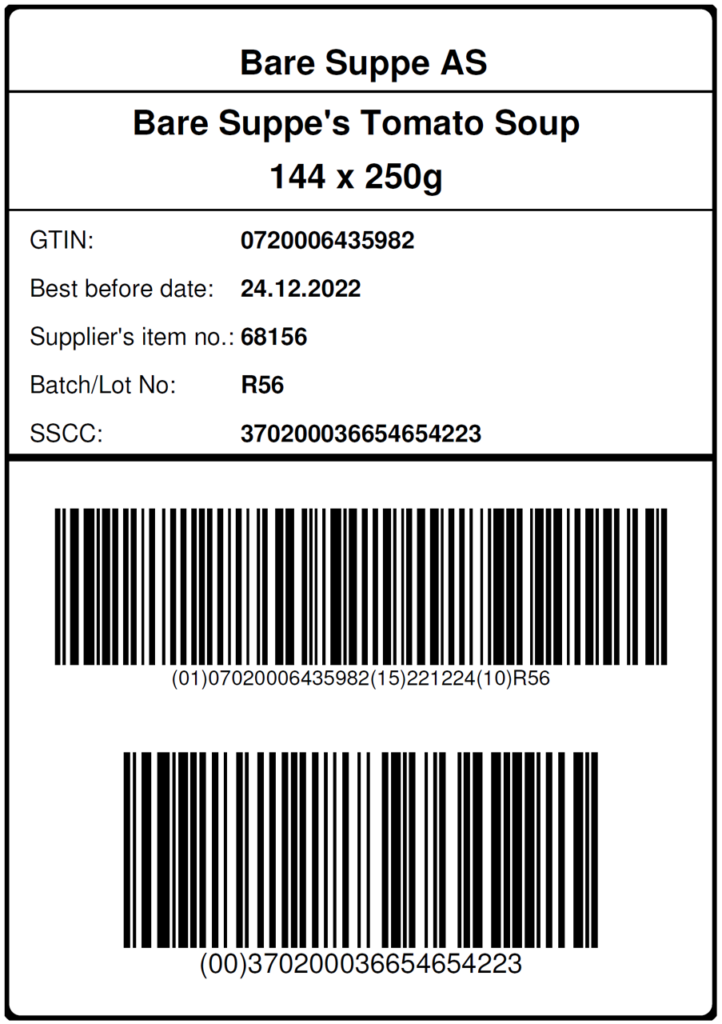

Product information on Stock Keeping Unit (SKU), with example of Stock Keeping Unit (SKU) label

Only product information should be labelled on a Stock Keeping Unit (SKU).

What information to be labelled depends on the type of product.

Intermediate Cartons shall be labelled as Stock Keeping Units (SKU)

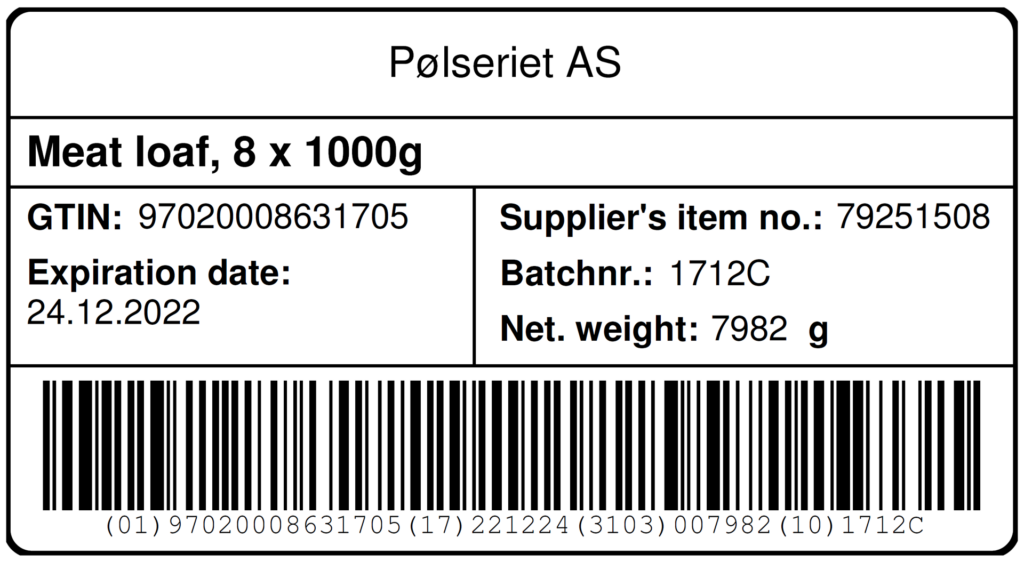

Possible product information which SHALL or CAN be labelled on a Stock Keeping Unit (SKU)

GTIN – Global Trade Item Number

Includes GTIN-8 (8 digits), GTIN-12 (12 digits), GTIN-13 (13 digits) and GTIN-14 (14 digits).

All Stock Keeping Units (SKU) must have their own GTIN.

– For variable measure Stock Keeping Units (SKU), GTIN-14 with a leading digit 9 should be used.

– For other products, GTIN-13 is recommended.

Name of brand owner

– shall be shown in plain text either on the label or on the packaging.

Product name

– Must be written in plain text on the Stock Keeping Unit (SKU) product label.

– Must be based on the text in the Norwegian grocery data pool – EPD database, and consists of product name, attributes, – and product description.

– The product description labelled on the Stock Keeping Unit (SKU) must be identical to the text in the Despatch Advice and Invoice.

-Product description should also contain a package description: for example, Coffee 12 x 500gr.

Batch / lot number

– A number generated by the manufacturer, used to achieve full traceability of product lot/batches in the value chain

– GS1-128 AI 10 must be used.

Shelf life information (“Best before” date, alternatively “Expiry date”)

– Must be labelled on all Stock Keeping Units which has shelf life printed on the Consumer Unit (CU)

GS1-128 AI 15 shall be used for «Best before date”

GS1-128 AI 17 shall be used for «Expiry date»

Net weight

– GS1-128 AI 3103 shall be used for variable measure Stock Keeping Units (SKU).

– Net weight means weight of product excluding packaging (the same weight that is being invoiced).

Supplier’s item number

– can be labelled in plain text.

Table showing what SHALL or CAN be labelled:

| Overview of product information that shall or may be labelled on Stock Keeping Unit (SKU): | ||||

| Information | Human readable text | GS1-128 (bar code) | AI | Format |

| GTIN for Stock Keeping Unit (SKU) | Must be labelled | Must be labelled | 01 | n2 + n14 |

| Name of brand owner | Must be labelled | Not labelled | ||

| Product name | Must be labelled | Not labelled | ||

| Batch / lot number | Must be labelled | Must be labelled | 10 | n2 + an..20 |

| Shelf life | Must be labelled if shelf life is marekd on the Consumer Unit (CU) |

Must be labelled if shelf life is marekd on the Consumer Unit (CU) |

15, alternatively 17 |

n2 + n6

|

| Net weight | Must be labelled for products with variable measures |

Must be labelled for products with variable measures |

310x | n4 + n6

|

| Supplier’s item no. | Can be labelled | Not labelled | ||

Example of GS1 Product label for Stock Keeping Unit (SKU), for a product with “Best before” date and a fixed weight:

Example of GS1 Product label for Stock Keeping Unit (SKU), for a product with “Expiry date” and variable measures:

Guidelines for labelling of Stock Keeping Units (SKU)

Type of bar code symbol

When labelling with bar code on Stock Keeping Units (SKU) GS1-128 bar code shall be used.

Identical information

Same information (GS1-128 AI) should only occur once per label.

Size and design of labels

Since the shape and size of the Stock Keeping Units (SKU) is highly varied, size and design of the label may also vary.

Quality of labels

It is a prerequisite that the labels are readable throughout the value chain for the entire life span of the unit. Therefore, the quality of GS1-128 bar codes must minimum fulfill print quality with “Grade C” according to standard ISO / IEC 15416.

To achieve “Grade C” when reading, “Grade B” or better is recommended at printing.

Quality of labels and bar codes can be verified at GS1 Norway.

Placement of labels on Stock Keeping Units (SKU)

It is recommended that the Stock Keeping Units (SKU) is labelled on two sides.

If labelling can only be done on one side, the label on the Stock Keeping Unit (SKU) must be on the same side as one of labels on the pallet (consistent orientation).

By column stacking the Stock Keeping Unit (SKU) label will be oriented towards one pallet label (either on the short or long side of the pallet).

By bond stacking (like bricks) the Stock Keeping Unit (SKU) label could be oriented towards the two labels of the pallet. That is, both on the short and the long side of the pallet.

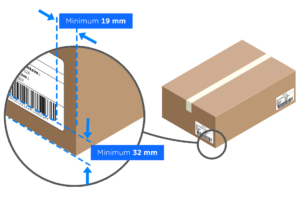

Bar codes

The following recommendations apply to GS1-128 bar code symbols:

- The orientation of the bar code should be such that the bars are vertical (picket fence).

- Size factor is in the range of 25 to 94% of nominal size.

- The minimum bar code height is 13 mm.

- Minimum 5 mm height on human readable text.

- The location of the bar code should be such that the bottom of the bar code is about 32 millimeters from the bottom of the Stock Keeping Unit (SKU).

- The bar code symbol included quiet zone (margins), must be at least 19 millimeters from a vertical edge to avoid damage to the label.

- If the height of the Stock Keeping Unit (SKU) is less than 50 mm, the bar code should be placed as high as possible and information to be written in plain text can be placed to the left of the bar code

Placement of bar code symbols on the Stock Keeping Unit (SKU)

Placement of bar code symbols on Stock Keeping Units (SKU) with height less than 50 mm

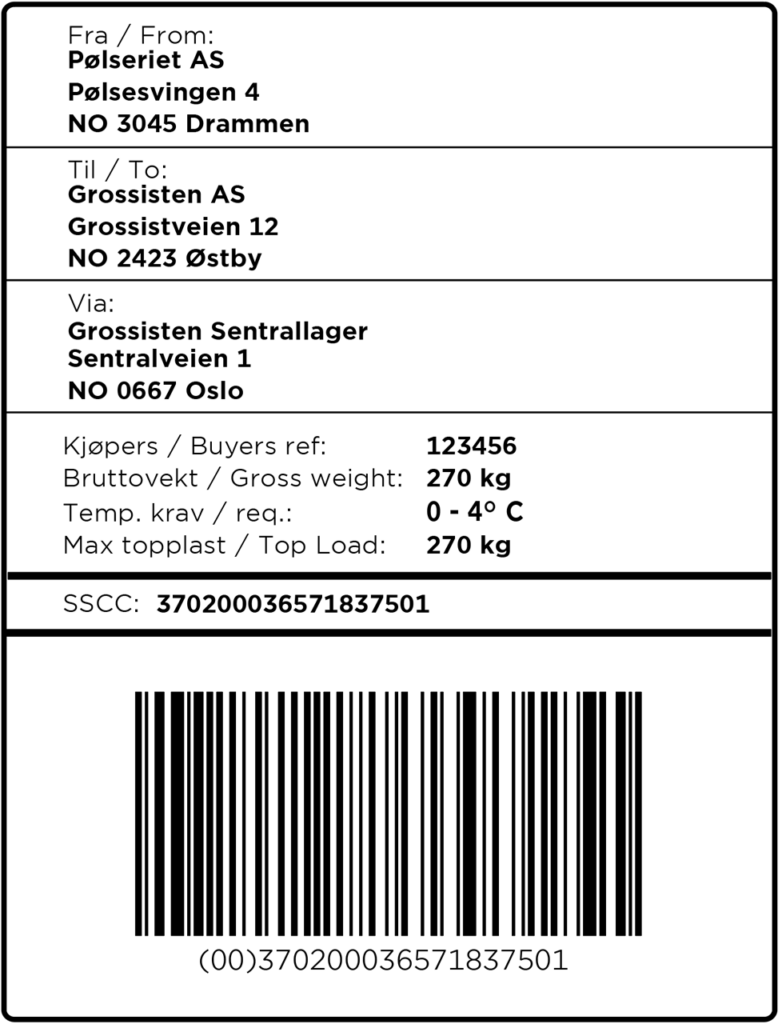

Transport information on pallet with example of transport label

Content of the Standard shipping label for the Norwegian grocery sector.

| Overview of labelling of Standard shipping label: | ||||

| Information | Human readable text | GS1-128 (bar code) | AI | Format |

| Sender’s name, street address, postal code, city | Must be labelled | Not labelled | ||

| Recipient’s name, street address, postal code, city | Must be labelled | Not labelled | ||

| Name, address, etc. for the Crossdocking terminal | Must be labelled when the delivery is via the Crossdocking terminal | Not labelled | ||

| Buyer’s reference | Must be labelled | Not labelled | ||

| Gross weight | Must be labelled | Can be labelled | 3300 | n4 + n6 |

| Max. Top load1) | Must be labelled | Not labelled | ||

| Temperature requirements | Must be labelled | Not labelled | ||

| SSCC (License Plate) | Must be labelled | Must be labelled | 00 | n2 + n18 |

| 1) Max Top load is omitted for Mixed pallet. | ||||

Example of Standard shipping label for the grocery industry

Transport label for Standard pallet

Standard pallet is labelled with Standard shipping label for the grocery industry

A GS1 product label on a Standard pallet requires labeling of SSCC, gross weight, top load weight and temperature requirements.

This information can therefore be omitted from Standard shipping label for the grocery industry.

If both product label and transport label are used, SSCC can be labelled on both labels provided that the identical number is used.

Transport label for Promotional Unit

The Distribution Unit (DU) containing one or more Promotional Units is labelled with Standard shipping label for the grocery industry.

The Distribution Unit (DU) is identified and labelled with its own SSCC

If the Promotional Unit a 1/1 pallet, the same labelling of transport label as for Standard pallet is used.

Transport label for Mixed pallet

Mixed pallet (both with and without interlayer pallet) is labelled with Standard shipping label for the Norwegian grocery industry.

If the Mixed pallet is not stackable, information on Top load is omitted.

Transport label for Customer packed pallets

The Customer packed pallet is labelled with Standard shipping label for the grocery industry.

Note in particular:

Recipient’s name, address, etc.

As recipient transit warehouse is given and transit address is given as delivery address. The pallet must be labelled with the transit warehouse’s name, street address, postal code and postal address in human readable text.

Name, address, etc. for the distribution warehouse.

The via-field the distribution warehouse is given. The pallet must be labelled with the distributions warehouse’s name, street address, postal code and postal address in human readable text.

Transport label for Customer packed units

Transport Information.

On this label, a separate field has been created for transport information. This is information that the buyer sends to the supplier in his order and which the supplier must put on the Customer packed unit’s transport label.

Format and content of transport information is agreed between the parties.

Content in transport label for customer packed unit

| Transport label for customer packed unit: | ||||

| Information | Human readable text | GS1-128 (bar code) | AI | Format |

| Sender’s name, street address, postal code, city | Must be labelled | Not labelled | ||

| End recipients’s name, street address, postal code, city | Must be labelled | Not labelled | ||

| Name, address, etc. for the transit warehouse1) | Must be labelled | Not labelled | ||

| Transport information2) | Must be labelled | Not labelled | ||

| Buyer’s reference3) | Must be labelled | Not labelled | ||

| Gross weight4) | Must be labelled | Can be labelled | 3300 | n4 + n6 |

| Temperature requirements | Must be labelled | Not labelled | ||

| SSCC Code (licence plate) | Must be labelled | Must be labelled | 00 | n2 + n18 |

| 1) Transit Warehouse where the pallet is split/cross-docked, is stated in the VIA-field | ||||

| 2) Transport information is agreed between the parties | ||||

| 3) Example The Customers Ordering Number | ||||

| 4) Gross weight is the sum of weight of the products, packaging materials and pallet (load carrier) | ||||

Example of shipping label for Customer packed unit

Product information on Distribution Unit (DU), with example of Distribution Unit (DU) label

The standard differs on different types of pallets depending on the content.

Only Standard pallet and Promotional Unit can provide a clear labelling of product information that applies to the entire pallet.

Standard pallet

A Distribution Unit (DU) containing the same product (same GTIN) with fixed count of Stock Keeping Units (SKU) and where labelling of unique product information on the Distribution Unit (DU) is possible.

It is recommended that a Standard pallet only contain Stock Keeping Units (SKU) with the same batch / lot number and shelf life date.

There are two different types of Standard pallet:

- Standard pallet with height 120 cm

- Standard pallet with height 60 cm (Standard Pallet – Low)

Standard pallet – Low is used for low-frequency products and for products with short shelf life.

A product can only be used on one type of Standard pallet, either 120 cm height or 60 cm height.

Standard pallet with height 120 cm

Standard pallet with height 60 cm (Standard pallet – Low)

Standard pallet shall be labelled with product and transport information.

Since product information and transportation information are usually known at different times, the practical solution is to label the device with two different labels:

- Product information label (incl. SSCC)

- Label with transport information

Product information on the GS1 product label for Standard pallet

SSCC (License Plate)

Must be labelled with GS1-128 AI 00 on the GS1 Product label on each Standard pallet in human readable text and in the bar code. The SSCC provides a unique identification of each Distribution Unit (DU). Because of traceability a SSCC shall not be reused until after a minimum of 6 years.

The bar code containing the SSCC should be the lowest bar code on the label. It is recommended to have a bar code containing only the SSCC and no other AI’s.

GTIN – Global Trade Item Number

Standard pallet must be labelled with GTIN. This can be done in the following ways:

- Primarily, GTIN for the Stock Keeping Unit (SKU) should be used

- GS1-128 AI 02 must be used. The count of Stock Keeping Units (SKU) is also required on the Distribution Unit (DU) using GS1-128 AI 37

- The Distribution Unit’s (DU) own unique GTIN can also be used, using GS1-128 AI 01.

Product name

The product’s name must be written in human readable text on the Distribution Unit’s (DU) product label. Product name must be based on the text in the Norwegian grocery data pool – EPD database, and consists of product name, attributes, and product description. The product description labelled on the Distributions Unit (DU) must correspond to the text in the Despatch Advice and the invoice.

Batch / lot number.

GS1-128 AI 10 is generated by the manufacturer and used to track the product back to specific production series.

If all Stock Keeping Units (SKU) on the pallet have the same batch / lot number, this is indicated on the label in human readable text and bar code. If the pallet contains Stock Keeping Units (SKU) with different batch / lot numbers, batch / lot number is omitted on the label. However, all unique batch / lot numbers must be stated in the electronic Despatch Advice.

Shelf life information

GS1-128 AI 15 should be labelled on all Distribution Units (DU) that contain Consumer Unit (CU) with “Best before date” printed on them.

Alternatively, the expiration date (GS1-128 AI 17) may be used for shelf life marking.

Net weight (in grams)

GS1-128 AI 3103 shall be used for variable measure products. Net weight means weight of product excluding packaging (the same weight that is being invoiced).

Gross weight (in whole kg)

Shall be labelled in human readable text on each Distribution Unit (DU). Gross weight means weight of products, packaging and pallet (load carrier).

Max. top load (in whole kg)

Must be labelled in human readable text.

Distribution Units (DU) that can not be stacked (in transport or storing) are marked with: Cannot be stacked (Kan ikke stables).

Temperature requirements

shall be labelled in human readable text if the product has a temperature requirement.

Product labelling on Standard pallet

| Overview of product information that shall or may be labelled on Standard pallet: | ||||

| Information | Human readable text | GS1-128 (bar code) | AI | Format |

| SSCC (License Plate)1) | Must be labelled | Must be labelled | 00 | n2 + n18 |

| GTIN for the Distribution Unit (DU)2) | Can be labelled | Can be labelled | 01 | n2 + n14 |

| GTIN for the contained Stock Keeping Units (SKU) | Must be labelled | Must be labelled | 02 | n2 + n14 |

| Count of Stock Keeping Units (SKU) on the DU | Must be marked except when DU is defined as an SKU | Must be marked except when DU is defined as an SKU | 37 | n2 + n..8 |

| Product name | Must be labelled | Not labelled | ||

| Batch / lot number3) | Must be labelled | Must be labelled | 10 | n2 + an..20 |

| Best before date4) | Must be labelled if Consumer Unit (CU) has printed best before date | Must be labelled if Consumer Unit (CU) has printed best before date | 15 | n2 + n6 |

| Net weight | Must be labelled for products of variable measure | Must be labelled for products of variable measure | 3103 | n4 + n6 |

| Gross weight | Must be labelled | Can be labelled | 3300 | n4 + n6 |

| Max. top load | Must be labelled | Not labelled | ||

| Temperature requirements | Must be labelled if the product has temperature requirements | Not labelled | ||

| 1) SSCC shall be indicated on the product label but permitted on both labels provided that the same number is used. 2) Can be used in a case for a transitional period. 3) If Batch / Lot No. is omitted on the Stock Keeping Unit (SKU), or it is different Batch / Lot No. on the Stock Keeping Units (SKU) this should not be labelled on the Distribution Unit (DU). 4) Alternatively, the expiration date (GS1-128 AI 17) may be used for shelf life marking. |

||||

Example on the GS1 product label for Standard pallet

Promotional Unit

A Unit defined as a Stock Keeping Unit (SKU) containing a fixed number of Consumer Unit (CU), intended for display in stores.

Promotional Unit can be 1/1 pallet, 1/2 pallet or 1/3 pallet.

Each Promotional Unit has its own load carrier.

Promotional Unit consisting of 1/2 pallet or 1/3 pallet are placed on a slave pallet. This constitutes a transport unit.

If slave pallet is omitted, this must be agreed bilaterally. For example, for 1/2 pallets with good stability, they can be tied together and exclude the slave pallet. This allows for better use of the pallet by increasing the Promotional Unit, thus allowing more items on the pallet.

Promotional Units are labelled with two levels of SSCC:

- At the lowest level is labelled with Product label for Promotional Unit as a Stock Keeping Unit (SKU) with the addition of SSCC. The product label is labelled on each Promotional Unit.

- The whole Promotional Unit is labelled with Standard shipping label for the groceries sector. If the Promotional Unit is a 1/1 pallet, this is labelled as a Standard pallet.

Labelling of Promotional Units provides increased traceability in the value chain

Product information on the GS1 product label for Promotional Unit

SSCC (License Plate)

Must be labelled with GS1-128 AI 00 on the GS1 Product label on each Promotional Unit in human readable text and in the bar code. The SSCC provides a unique identification of each Distribution Unit (DU). Because of traceability a SSCC shall not be reused until after a minimum of 6 years.

The bar code containing the SSCC should be the lowest bar code on the label. It is recommended to have a bar code containing only the SSCC and no other AI’s.

GTIN – Global Trade Item Number

Promotional Unit must be labelled with GTIN. This can be done in the following ways:

- Primarily, GTIN for the Stock Keeping Unit (SKU) should be used

- GS1-128 AI 01 must be used

Product name

The product’s name must be written in human readable text on the Distribution Unit’s (DU) product label. Product name must be based on the text in the Norwegian grocery data pool – EPD database, and consists of product name, attributes, and product description. The product description labelled on the Distributions Unit (DU) must correspond to the text in the Despatch Advice and the invoice.

Batch / lot number

GS1-128 AI 10 is generated by the manufacturer and used to track the product back to specific production series.

If all Stock Keeping Units (SKU) on the Distribution Unit (DU) have the same batch / lot number, this is indicated on the label in plain text and bar code. If the Distribution Unit (DU) contains Stock Keeping Units (SKU) with different batch / lot numbers, batch / lot number is omitted on the label. However, all unique batch / lot numbers must be stated in the electronic Despatch Advice.

Shelf life information

GS1-128 AI 15 should be labelled on all Distribution Units (DU) that contain Consumer Unit (CU) with “Best before date” printed on them.

Consumer Unit (CU). Alternatively, the expiration date (GS1-128 AI 17) may be used for shelf life marking.

Net weight (in grams)

GS1-128 AI 3103 shall be used for variable measure Stock Keeping Units (SKU). Net weight means weight of product excluding packaging (the same weight that is being invoiced).

Gross weight (in whole kg)

shall be labelled in human readable text on each Distribution Unit (DU). Gross weight means weight of products, packaging and pallet (load carrier).

Max. top load (in whole kg)

must be labelled in human readable text.

Distribution Units (DU) that can not be stacked (in transport or storing) are marked with: Cannot be stacked.

Temperature requirements

shall be labelled in human readable text if the product has a temperature requirement.

Product labelling on Promotional Unit

| Overview of labelling of product information that may or may not be labelled on Promotional Unit: | ||||

| Information | Human readable text | GS1-128 (bar code) | AI | Format |

| SSCC (License Plate) | Must be labelled | Must be labelled | 00 | n2 + n18 |

| GTIN for Stock Keeping Unit (SKU) | Must be labelled | Must be labelled | 01 | n2 + n14 |

| Product name | Must be labelled | Not labelled | ||

| Batch / lot number1) | Must be labelled | Must be labelled | 10 | n2 + an..20 |

| Best before date2) | Must be labelled if Consumer Unit (CU) has printed best before date | Must be labelled if Consumer Unit (CU) has printed best before date | 15 | n2 + n6 |

| Temperature requirements | Must be labelled if the product has temperature requirements | Not labelled | ||

| Supplier’s item number | Must be labelled | Not labelled | ||

| 1) If Batch / Lot No. is omitted on the Stock Keeping Unit (SKU), or it is different Batch / Lot No. on the Stock Keeping Units (SKU) this should not be labelled on the Distribution Unit (DU). 2) Alternatively, the expiration date (GS1-128 AI 17) may be used for shelf life marking. |

||||

Example of Stock Keeping Unit (SKU) label with SSCC for Promotional Unit

Units where product information can not be entered on their own label

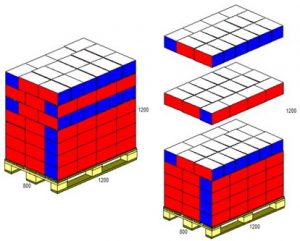

Mixed pallet

Two variants of Mixed pallets are described; with and without intermediate pallet.

On Mixed pallet it is not possible to enter product information on its own label.

Mixed pallet without intermediate pallet:

Pallet consisting of several different products.

Mixed pallet with intermediate pallet:

Pallet consisting of several different products, where each product is stacked in one or more layers, and where each different product is separated by an intermediate pallet.

The choice of type of mixed pallet depends, among other things, on handling costs, transport / environmental costs and storage technology and must be agreed bilaterally between the parties.

Packaging and stability of the Stock Keeping Unit (SKU) must be considered when choosing type of a Mixed pallet.

If intermediate pallet(s) are used, it shall always be ordered the amount of Stock Keeping Units (SKU) to complete a layer.

Mixed pallet (both with and without intermediate pallet) is labelled with Standard shipping label for Norwegian grocery sector.

Customer packed pallet

When a supplier assembles products for delivery to the final recipient, the products are packaged and labelled with SSCC at two packaging levels.

Customer packed units are labelled for delivery to the end-user and the Distribution Unit (DU) is labelled for delivery to the transit warehouse.

On Customer packed units it is not possible to enter product information on the Distribution Unit (DU) label.

A customer-packed pallet can be Customer packed unit – multiple route, multiple customers, Customer packed unit – single route, multiple customers, or Customer packed unit – single customer.

- Customer packed unit – multiple route, multiple customers is a unit of products for two or more end recipients that will be split in transit storage.

- Customer packed unit – single route, multiple customer is a unit of products for two or more end recipients on the same route or transport.

- Customer packed unit – single customer is a unit of products that are intended for only one end recipient.

This Customer packed units does not need to have its own load carrier and is being loaded on a standardized transport unit (for example, an EUR pallet).

Customer packed unit – multiple route, multiple customers and Customer packed unit – single route, multiple customer is stacked in columns per. end receiver.

Customer packed unit – multiple route, multiple customers is split after products receipt in the transit warehouse, and the individual Customer packed unit is forwarded to the final recipient. A prerequisite is that all Customer packed units located on one Distribution Unit (DU) are destined for the same transit warehouse.

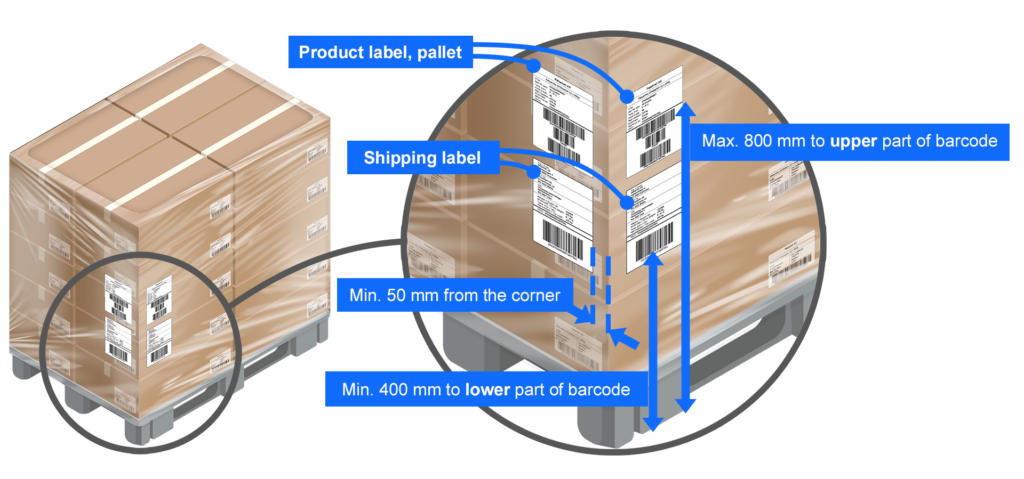

Guidelines for labels on Distribution Units (DU)

Placement of labels on pallet

Two types of labels shall be used; label for product information and label for transport information.

- The minimum requirement is that the pallet should be labelled on two sides with both label types; one of the short sides of the pallet and the right hand long side (seen from the short side).

- Product and transport label must be on the same side of the pallet.

- When multiple labels are used on the same side of the pallet, the labels should be placed underneath each other. The label that contains SSCC placed at the bottom.

- The labels should be placed so that the bottom of the lowest bar code should be at least 400 mm above the floor, and the top of the uppermost bar code should not be more than 800 mm above the floor.

- The label should be placed at least 50 mm from the vertical edge.

- For pallets lower than 400 mm the labels should be placed as high as possible.

- If all information is known at the time the pallet is labelled and there is space on the label, all information can be labelled on one single label.

- To ensure automatic reading of the bar codes Promotional Units, Customer packed pallet and Mixed pallet should only the transport label on the transport unit be readable

- Product label on Standard pallet with height 60 cm (Standard pallet – Low) should be placed as high as possible.

Identical information

Same information (GS1-128 AI) shall only appear once on the product and transport label.

This means in practice that the same information can not be repeated on the same label or that the same information may appear on multiple labels on the device (pallet).

The exception is SSCC which is allowed on both labels if it is an identical number used.

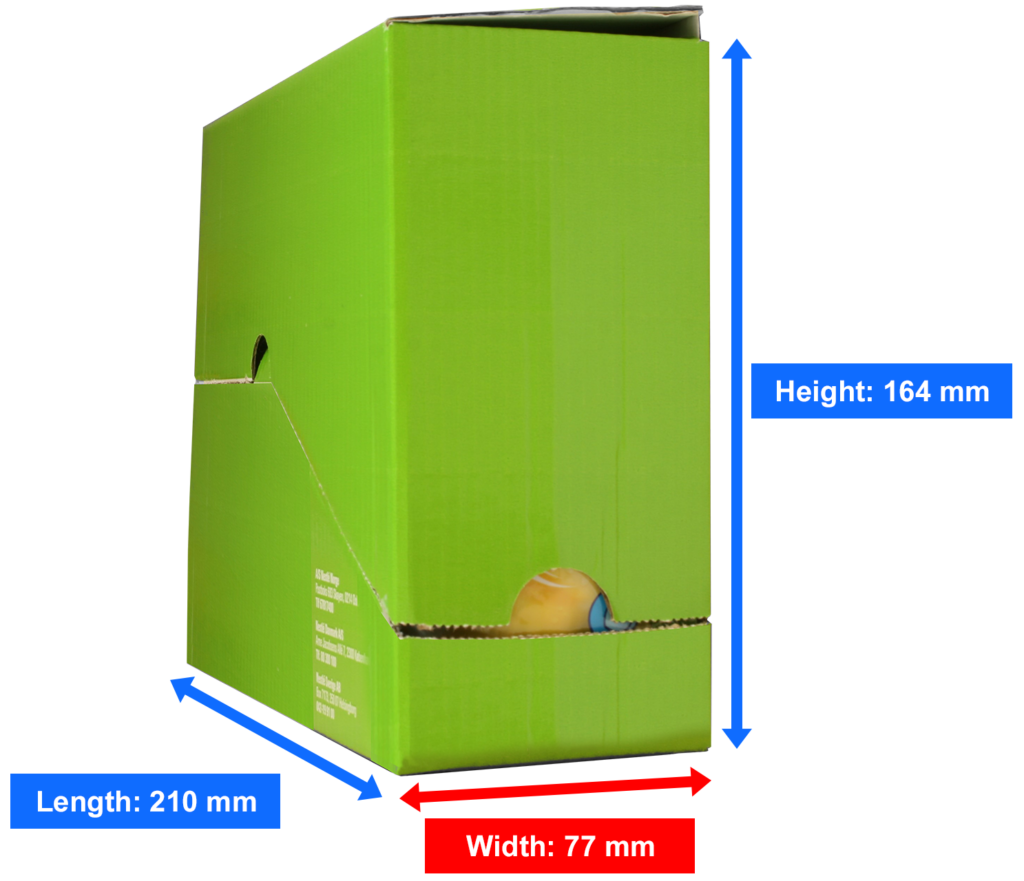

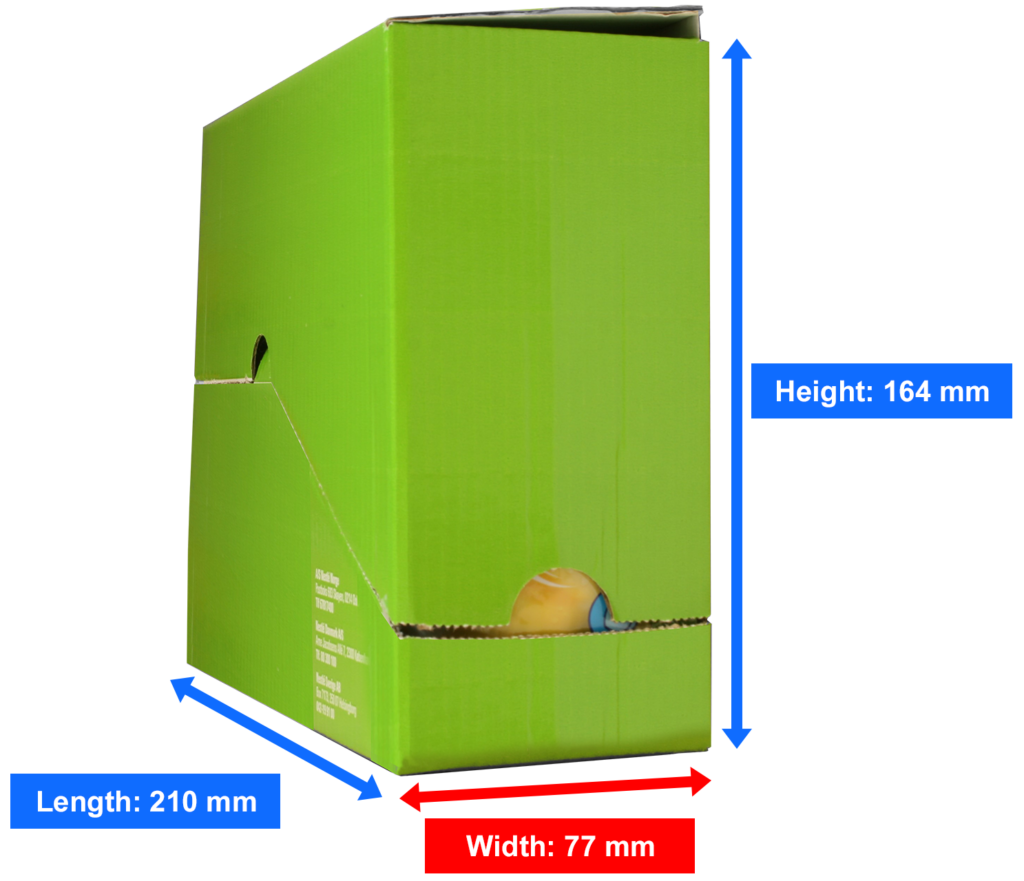

Size and design of the labels

The following recommendation applies:

- The width of the label should be 105 mm or 148 mm

- The height of the label may vary

Recommended formats are:

- A5 (148mm x 210mm)

- A6 (105mm x 148mm)

- 105 mm x 192 mm

Quality of labels

- It is a prerequisite that the labels are readable throughout the value chain for the entire life span of the unit

- It is a requirement that the quality of GS1-128 bar codes minimum meets print quality with “Grade C” according to Standard ISO / IEC 15416.

To achieve “Grade C” when reading, “Grade B” or better by printing is recommended - When affixing the labels, it is important to ensure that the bars in the GS1-128 symbol are correct and unbroken (avoid “wrinkling” on the label).

Bar code requirements for labelling with GS1-128 on Distribution Units (DU)

Bar code label with GS1-128 bar codes shall be done according to GS1 General Specifications Chapter 5.4.

Note in particular:

- Size factor is in the range of 50 to 94% of nominal size.

- The minimum bar code height is 32 mm.

- When labelling GTIN (AI 01 and AI 02) always use 14 digits.

When GTIN has 13 digits, you must enter a leading 0 (ex. 07038010000065). - For bar code labelling with GS1-128, a separator, called Function Code 1 (FNC1), is used between the individual information elements (AI’s).

This applies except for the AI’s that have predefined fixed length.

The following AI’s in this document have predefined length AI 00, AI 01, AI 02, AI 15. - It is recommended to have the AI’s to be followed by FNC1 at the end of the bar code, as the FNC1 code may be omitted.

- It is important to the requirements for quiet zone (margins) to be adhered to.

At size factor 50%, the right and left quiet zone margin is 5 mm, and at the size factor 94% the quiet zone margins are 9.4 mm.

Requirements for design of Stock Keeping Unit (SKU) and packaging

Stock Keeping Unit (SKU) is the unit the retailer buys.

Stock Keeping Unit (SKU) occurs in various forms, such as carton, reusable box / pallet box, intermediate carton and such.

The most important task of the Stock Keeping Unit (SKU) is to secure Consumer Units (CU) from the time of manufacturing until it is finished exposed in a shop shelf.

The number of Consumer Units (CU) in a Stock Keeping Unit (SKU) is determined by the manufacturer, preferably in dialogue with the distributor / retail chain.

The Stock Keeping Unit (SKU) must be adapted to the modular system, see Modular system

for picking and grouping of products can be done as efficient as possible.

Case fill rate shall be calculated. This is described in Case fill rate

Stock Keeping Unit (SKU) must be designed to withstand the strain required in the value chain.

Automatic warehouses require that Stock Keeping Units (SKU) must be packed in a way that it can be lifted, stacked, clamped and handled with different mechanized devices, see Automated warehouse at distributor – greater understanding of the depalletization process.

Design requirements and packaging

When designing a Stock Keeping Unit (SKU), it must be based on the modular system.

This means that the Stock Keeping Unit (SKU) should not be less than 100 x 150 mm and not more than 400 x 600 mm.

Example of best practices

Modular Stock Keeping Unit (SKU).

Example of an inappropriate Stock Keeping Unit (SKU)

Stock Keeping Unit (SKU) is not adapted to the modular system.

The size of the Stock Keeping Unit (SKU) must consider the size of the shelf space for the current product group.

The short side of the Stock Keeping Unit (SKU) should be front where appropriate.

There must be a simple and clear opening guide, preferably with illustration.

The packaging must be opened without using a knife.

When the Consumer Units (CU) is exposed in the Stock Keeping Unit (SKU), the least possible of the Stock Keeping Unit’s (SKU) packaging should be visible when exposed in the store shelf.

Stock Keeping Unit (SKU) must not weigh more than 15 kg.

Stock Keeping Unit (SKU) must be in recyclable cardboard or plastic.

Example of an inappropriate Stock Keeping Unit (SKU)

Lid / plastic film is missing, which may cause Consumer Unit (CU) to fall out during internal transport.

Plastic boxes – all variants – must be considered to work in automated warehouse handling.

Stock Keeping Unit (SKU) must be form stable.

Example of best practices

Stock Keeping Unit (SKU) is form stable.

Example of best practices

Form stable Stock Keeping Units (SKU) that embraces close to its content and is strong enough to not deform.

Resists load on inbound transport (2 pallets in height), as well as handling through the value chain.

Example of an inappropriate Stock Keeping Unit (SKU)

Not form stable. Do not resist strain on inbound transport (2 pallets in height), as well as handling through the value chain.

Stock Keeping Unit (SKU) that is only wrapped in plastic foil must have a tray / trough below.

Example of best practices

Stock Keeping Unit (SKU) on tray / trough with plastic wrap.

Stock Keeping Units (SKU) must have straight sides.

Example of best practices

Stock Keeping Units (SKU) with straight sides.

Glue quality and amount of glue on Stock Keeping Unit (SKU) must be such that glued surfaces do not loosen.

Example of best practices

Glue quality and amount of glue is such that glued surfaces do not loosen.

Constructed example of an inappropriate Stock Keeping Unit (SKU)

Too little glue / too few glue points are included that flap gaps with subsequent stops in automatic warehouse systems.

The Stock Keeping Unit (SKU) should be stackable and “ears” should only be used where it is necessary for stability.

Should “ears” be used, these should not exceed 5mm and should not be used in conjunction with intermediate pallet sheets.

Stock Keeping Unit (SKU) should not have loose lid.

The lid must be attached to the tray / trough in such a way that it does not loosen during handling. It is recommended to use glue points or a locking mechanism.

The Stock Keeping Unit (SKU) must have a center of gravity relative to the base that allows it to be handled on conveyor belts.

The height / width ratio should be below 1.7 to ensure that the products do not fall under internal transport in an automatic warehouse.

Example of best practices

The ratio height / width is below 1.7.

Example of an inappropriate Stock Keeping Unit (SKU)

The height / width ratio is over 1.7, which means that the Stock Keeping Unit (SKU) can fall during internal transport.

Stock Keeping Unit (SKU) exposure front should not be less than 30 mm, regardless of the chosen solution.

The information on the Consumer Unit (CU) must be visible.

Packaging capacity

During the design of the product and packaging it must be considered that the outer dimensions of the finished Stock Keeping Unit (SKU), tray and otherwise, under the load of the above-mentioned product packaging, due to bulging, is within the margin. In practice, this can be from 0.5 to 1.0 cm.

Optimal transport requires the use of load capacity of the transport systems (weight and height).

Generally, the packaging should be able to carry a similar pallet (2 identical pallets) without any breakage or clamping damage during transport and storage.

Exceptions from this must be specified and labelled on the (Distribution Unit (DU).

Method of calculation of carrying capacity is described in Top load labelling system.

The packaging shall be able to withstand shipping with other products for shipping to the store in a rational way.

In order to achieve the industry’s common goal of efficient flow of products, reduced negative environmental impact, promoted sales and reduced losses, it is important to focus on:

- Top load

- Stackability

- Module customization

Especially for reusable boxes / pallet boxes

Basically, Stock Keeping Units (SKU) is desired in cardboard, or in combination with plastic.

Reusable boxes are an alternative to Stock Keeping Units (SKU) in corrugated paper but must be agreed bilaterally.

Particularly for Intermediate cartons

The use of Intermediate cartons should be kept as low as possible and must be agreed bilaterally.

Intermediate cartons are accepted in cases where the Stock Keeping Unit (SKU) solution is not possible because the Stock Keeping Unit (SKU) does not meet the requirements for strength, stability or size and where the use of intermediate pallet sheet on pallet is not possible.

The intermediate carton must be labelled so that it clearly differs from the Stock Keeping Unit (SKU) and shall not weigh more than 15 kg.

Requirements for the design of the Distribution Unit (DU) and palletization

The Distribution Unit (DU) is the unit the Stock Keeping Units (SKU) is stacked on / packed in for transport to distributor.

Design of a Standard pallet (Standard pallet and Standard pallet – Low)

A Standard pallet must contain the same product (same GTIN) with a fixed number of Stock Keeping Units (SKU), in a fixed pallet pattern, with equal number of Stock Keeping Units (SKU)on each layer, and where labelling of unique product information on the Distribution Unit (DU) is possible.

The pallet structure shall contain as little excess volume of “air” as possible.

Standard pallet

Maximum pallet height must be 1200 mm incl. pallet. All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers.

Tolerance limit for existing products is 1249 mm.

Standard pallet – Low

Maximum pallet height shall be 600 mm incl. pallet.

Standard pallet – Low is used for low-frequency products and for products with short shelf life.

Principles for the construction of a palletpattern, central in calculation of top load weight, ref Top load labelling system.

When creating a pallet pattern, the following applies:

- A packaged Distribution Unit (DU) must be form stable and handling-friendly

- A Distribution Unit (DU) shall withstand regular transport, handling and storage through the value chain

- For single article Distribution Units (DU), all layers must contain the same number of Stock Keeping Units (SKU), and in a fixed pallet pattern

- Requirements for equal number of Stock Keeping Units (SKU) on each pallet / identical layer from pallet to pallet, with the possibility of variation between the layers

- The pallet should not have overhang

- The Stock Keeping Unit (SKU) should be placed on the pallet as it is exposed in the store

- Do not glue between pallet layers or between Stock Keeping Units (SKU) in the same pallet layer

- If a transport label or product label is attached directly to Stock Keeping Unit (SKU), the label must not overlap between 2 Stock Keeping Units (SKUs), either horizontally or vertically

- All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers.

Types of pallet pattern

When constructing Distribution Units (DU), the Stock Keeping Unit (SKU) must be placed in accordance with a given pallet pattern. These are referred to as bond stacking and column stacking. Pallets can also be built as a combination of bond stacking and column stacking.

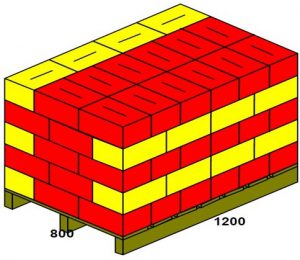

Bond Stacking

Bond Stacking means that the units on every other layer are different, thus locking each other to a greater or lesser extent, but it reduces the compressive strength by approx. 40%.

Example of good pallet utilization and stacking with bond stacking, for good stability.

Column Stacking

Column stacking means stacking packages on top of each other without overlapping with other packages. This form of stacking gives maximum strength in terms of pressure load due to that the corners have better roll stiffness than the sides, but the stack gives poor stability without additional use of shrink wrap, strap, ribbon or similar.

Example of column stacking in the lower pallet layers, and bond stacking on the top layer. Combining the different stacking methods achieves good stack strength on the lower layers while the pallet is locked on top.

This is often a good alternative to intermediate pallet sheets.

Use of plastic to secure the pallet through the value chain

- Shrink / stretch film must not be so tight that the packages are deformed

- Shrink / stretch film must be tight around to the pallet

- No tail of plastic must hang loose

- Shrink / stretch film must not cover the fork lift openings on the pallet

- Shrink / stretch film must not be fastened around the pallet blocks

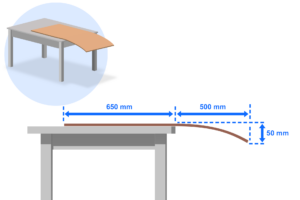

Use of intermediate pallet sheets

Intermediate pallet sheets must be minimized and used only if this is necessary to ensure quality and transportability of the pallet.

Intermediate pallet sheets are preferred if the alternative to this is intermediate cartons, “Ears” on the Stock Keeping Unit (SKU) or use of corner trims.

Where intermediate pallet sheets are used, the following requirements apply:

- The pallet sheet to be used for standard euro pallet should have dimensions of 750 mm * 1150 mm, ie 50 mm less than the length and width of the current load carrier

- The pallet sheet must be of rigid cardboard or corrugated cardboard.

- The stiffness of the pallet sheet must pass the following test: If the short edge of the plate hangs 500 mm from a flat surface (eg a table), the pallet sheet must not bend down more than 50 mm, see illustration below

- No more than one intermediate pallet sheet between each layer

- The intermediate pallet sheet must not be fastened and be flat

- Only a whole intermediate pallet sheet, i.e. without holes or perforations, shall be used

- In case of questions, one is encouraged to contact the packaging supplier

See also Automated storage at distributor – greater understanding of the depalletization process

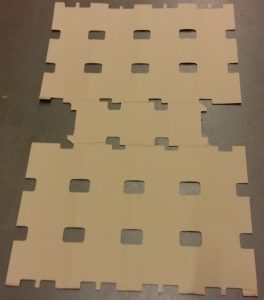

Example of intermediate pallet sheet that does not meet quality requirements. The intermediate pallet sheet is a thin paper and is not suitable for automatic warehouse systems

Example of what happens when using “thin paper” intermediate pallet sheets.

The sheet is hanging down in the robot. It blocks for sensors that check that the layer is separated from the rest of the pallet. The robot will stop, and manual error correction must be carried out before the machine can be restarted.

Example of pallet with intermediate pallet sheets, too big – hanging on outside the pallet.

Is not suitable.

Intermediate pallet sheets with holes. Is not suitable.

Endringslogg

Placement of Stock Keeping Unit (SKU) on pallet

It is a prerequisite for maintaining strength, that Stock Keeping Units (SKU) are placed within the edges of the pallet with a small margin.

Devices placed on or outside the edge can cause damage with subsequent reduced carrying capacity / risk of injury.

The pallet area should be utilized as best as possible with products. By following the Modular system optimal use of the pallet is ensured and reduces the risk of the load shifting during transport.

Overhang is not accepted.

Guidelines and routines for tracking, recall and withdrawal

In its framework, STAND has defined guidelines, recommendations and best practices for how products should be marketed in the distribution chain, and how information on this should be exchanged between the parties.

Central to this is the consideration of the consumer and his expectation for safe food.

The guidelines for tracking, recall and withdrawal do not define food quality requirements, but describe what procedures and processes the industry has established to mitigate any unwanted effects should an incident or crisis occur in a product.

Best practices

The guidelines describe best practices in this area.

By following STAND’s framework, the guidelines will be achievable for all parties involved.

Some important prerequisites for best practice.

- Routines and processes must be simple, predictable and intuitive

- Products and deliveries / load carriers must be labeled in a unified, standardized and correct way so that they can be traced through the value chain.

- Product information must be registered in the Tradesolution EPD

- Detailed tracking information must be exchanged digitally between the parties and follow the products through the value chain.

- Action must be taken quickly when an incident or crisis occurs

By ensuring that a total industry complies with STAND’s framework, consumers’ demands and expectations for safe food are fully met.

Objective of the guidelines

The guidelines are aimed at “Contribute to meet consumers’ expectations for safe products”.

Target Audience:

- Anyone who may or will be involved in any recall or withdrawal

- Everyone involved in the production or labeling of products and packaging covered by the guidelines

Products / areas to which the guidelines apply:

- Recommended for food and non-food products, except pharmaceuticals

- Other inputs, plants, animals or foodstuffs

- Materials and articles that are intended to come into contact with, or may affect, inputs or foodstuffs.

Medicines are exempt from the guidelines. Here we refer to separate regulations, not described here.

Certain types of food may be subject to additional regulatory requirements beyond what is described here. An example is the EU’s new tobacco directive (EU 2014/40) which make the requirements for traceability of tobacco products more stringent, but is not described here.

Routines covered by the guidelines

Legislative anchoring of the guidelines

The guidelines are among others based on Norwegian or European regulations on food safety and traceability:

- Product Liability Act of 23 December 1988

- Act on food production and food safety, etc. of 19.12.2003 Matloven (Food Law)

- Regulations on internal control to comply with IK-mat forskriften (IK Food Law)

- EU Food Law (Regulation EC 178/2002)

- Directive 94/62 / EC on packaging and packaging waste

Each party has an obligation to familiarize themselves with the regulations that apply to the products your business sells or are involved in.

The legislation does not impose requirements on how tracking should be performed, and what systems in which tracking information should be recorded. Manual systems may be sufficient as long as the requirements for tracking and tracking information are met.

Routines

The guidelines cover two procedures

- Requirements for and how to design contingency routines

- Implementing actions should an incident or crisis occur

Prepare crisis procedures

This is included:

- Prepare a Risk Analysis

- Prepare a Contingency Plan

- Requirements for product tracking

- Tracking information and labeling requirements

Prepare a Risk Analysis

At the heart of the legislation is the duty of each company to carry out a risk analysis of the health risks the products represent and how the company will relate to this in terms of traceability.

The purpose of the analysis is to reduce / prevent risk through

- Withdrawal of products from the market, or

- Efficient notification or recall of products from consumer

This assumes that the parties are aware of the risks the products may pose and have a preparedness that ensures that they react quickly, correctly and effectively in unwanted incidents. A Risk Analysis should therefore be performed on new products based on an intended relevant incident, so that it can be implemented as quickly as possible should a real incident occur for the product.

The risk analysis consists of three elements that both the government and industry should work on in an equal way:

- Risk Assessment

- Risk Management

- Risk Communication

See more about risk analysis here Design and content of a Risk Analysis.

Prepare a Contingency Plan

If unwanted incidents or crises occur, it is important to be well prepared.

Possible scenarios for what might arise should be thought through and how this should be handled.

A Contingency Plan must be prepared that will allow you to cope with the situation quickly, correctly and effectively. The Contingency Plan must be accurate and accessible to all involved at all times.

The Contingency Plan includes:

- To designate a crisis team, responsible for traceability, recall and withdrawal.

- Internal and external contact lists to quickly reach everyone involved or affected by any incident or crisis

- Training and exercises in the company’s routines and instructions on how to handle incidents or crises. Exercises should be as realistic as possible and carried out with the closest business partner in the value chain

- This must be easily accessible and may consist of, for example

- a brief overview of crisis teams with their roles and responsibilities

- the company’s internal guidelines for handling incidents / crises

- contact lists

- other relevant documentation that is important to have access to should an incident or crisis occur

See more about the Contingency Plan here Design and contents of a Contingency Plan.

Product tracking requirements

The legislation requires that each company must have systems to document which products are purchased from each supplier and which customer has purchased the company’s finished products.

This also includes raw materials and other input that are covered by the legislation.

There is no requirement in the legislation for which type of systems to be used for this.

Businesses can practice more comprehensive tracking systems than the minimum regulatory requirements require, but this is either based on self-imposed requirements or agreements with, and orders from the contracting parties.

Tracking means being able to follow the physical flow of goods. This is often referred to as chain traceability, and assumes that all parties meet the requirements and follow the guidelines for tracking.

Tracking takes into account the legal requirements for all parties to be able to trace their products one step forward and one step back in the value chain.

Tracking one step forward:

This means to the address the products are delivered to.

An invoice system containing information about item number / item name, customer number / customer name and invoice date is sufficient to be able to trace one step forward in the value chain.

If the company is using batch/lot numbers for their products, this should be included in the invoice, despatch advice and the like, or linked directly to the company’s own systems.

Tracking one step backward:

This means the address from which the products are delivered.

The company must keep a log of received products describing which products were purchased from whom and in which quantitiy, and date.

If the addresses for where products are delivered from or delivered to are not in accordance with the legal ownership of the products and the invoice process, this should be agreed separately between the parties.

Requirements for tracking information and labeling

The main purpose of the tracking information is to lay the groundwork for effective blocking, withdrawal or recall of products.

Central tracking information is:

- GTIN (Global Trade Item Number) – Unique identification of products

- GLN (Global Location Number) – Unique identification of trading parties, pick-up points, delivery points etc.

- SSCC (Serial Shipping Container Code) – Unique identification of load carriers / pallets

- Batch / lot number – A unique batch or lot number defined by supplier / manufacturer

- Shelf life – Either Best Before date or Last Consumption Date

It is a requirement that the products are labeled to enable tracking.

The marking must be affixed to the product packaging and legible.

The following applies to finished goods traded between supplier and distributor / retailer:

Information to be marked:

- The name of the supplier

- Product name/description

- Product number identified with a GTIN.

- Best before date / last day of consumption date, if required

- Batch / Lot number, if required

Load carrier (for example pallet) shall be marked with SSCC.

The sender must in his system have an overview of which recipient the product was sent to, and also the recipient must have an overview of which sender the product was received from. Both sender and recipient must be identified with GLN.

Sender shall in his system register:

- Quantity sent

- Shipping Date

- Reception date (if known)

Recipient shall in his system register:

- Quantity received

- Shipping date (if known)

- Reception Date

The following applies to raw materials and other inputs:

- GTIN should be used for identification of inputs / raw material, if available

- GLN should be used for identification of sender / suppliers, if available

More about tracking information and how the product can be tracked in the value chain is described here Recommended traceability methods in the value chain.

Actions to be made in case of an incident or crisis

Alarm / Notification

An incident can occur in all steps of the value chain, at the consumer, retailer, distributor or at the supplier itself. It is important that the supplier is notified as soon as possible.

Notification of an incident shall be given to one alert point at each operator. The alert point should be agreed in advance and always be staffed / available.

The industry has decided that for products registered in the Tradesolution EPD base, Tradesolution ReCall portal should be used for blocking, recall or withdrawal. Access is available at epd@tradesolution.no

For products not registered in the Tradesolution EPD base, a Notification schema for recall, withdrawal or blocking of a product may be used provided that this has been agreed between the supplier and the distributor/wholesaler. Notification schema can be downloaded from Downloads.

Required information to follow an alarm / alert

To identify the scope of the alarm / alert, the product’s GTIN / EPD, best before date, batch / Lot number and SSCC on affected pallets must always be stated. This applies regardless of whether the product is registered in the Tradesolution EPD base or not.

By using the portal, the supplier gets / is secured

- Easier, faster and more efficient registration, as well as quality assurance of the necessary product information

- Ensure that necessary information is distributed quickly and efficiently to all relevant recipients

- Simplifying the dialogue between the parties

- All dialogue and information exchange is done in the portal and can be logged and stored.

The ReCall portal can also be used in situations where you want to withdraw products with quality defects.

Distributors have built their own systems and routines for alerting crisis situations and blocking the products at their distribution warehouses and retailers. This is not part of the ReCall portal.

The following routine applies when registering an incident or crisis

- Register a new case

- Determine severity and health hazards

- Notify affected parties / recipients

- Register distribution and what to do with the product

- Register tracking information for affected batches / lots

- Describe further actions to be taken, with press releases and other additional information

- Closing the case

The practical implementation of the routine is described here Routine when registering an incident or crisis, in the Tradesolution ReCall portal.

Conclusion

Through the guidelines, the industry contributes to satisfying consumers’ demands and expectations for safe products, provided that an overall industry complies with the guidelines.

Should an incident or crisis occur, there are routines and tools that, in a simple, fast and secure way, limit incidental damage.

An accurate and limited recall or withdrawal will be possible.

This reduces costs for all parties in the value chain and minimizes potential reputational loss.

Service Level – Purpose, types of target measures and assumptions

Intentions for measurement of service level

Measurement of service levels is a topic that most players are concerned with and are an important element in the relationships between supplier and customer.

The parties are free to agree whether to measure the degree of service.

If the parties agree to establish an agreement, STAND recommends that STAND’s definitions be used.

A challenge in relation to the exchange and evaluation of service level data has been that the trading partners often use different definitions and conditions for measurement and follow-up.

The recommendation contains suggestions for target measures and common definitions for measuring service levels. The purpose is to establish a common platform as a basis for measurement, communication and mutual evaluation of performance.

Joint exchanges of measurement results, based on the proposed definitions, could contribute to improved service levels and contribute to increased understanding of the parties’ views on customer and delivery services.

Target measures are based on DLFs (Dagligvaruleverantörers Förbund) and DULOGs (Dagligvaruhandelns Utvecklings- och Logistikgrupp ) common definitions, established in Sweden in 1998.

With this as a base as well as experience from companies with international relations, the prioritized definitions build upon the need for common understanding, measurement and evaluation of cross-border service.

With continuous follow-up, development and trends can be monitored over time. This will probably be more interesting than single results. Greater trend deviations are when warning signals and improvement programs should be implemented to reduce the likelihood that a similar situation will arise in the future.

Target measures

The recommendation describes 6 different target measures, of which STAND recommends that 3 of these are prioritized, as these can be quickly implemented in today’s systems.

Other target measures are composed of different combinations of priority targets.

Selection of target measures is done by the parties themselves and described in bilateral agreements.

The industry has an increasing focus on improving the service level to consumers, ie reducing out-of-stock in the stores. This is currently being worked on, including developing agreed definitions of how this should be measured and followed up. The following two KPIs can be used:

1. Lost sales:

When stock is zero at the end of the day, this will be set off against lost sales in the store.

Example: You have sold 40 during the day, and at the end of the day, the stock is zero. If this item had a sales forecast of 100 that day, the shelf service level of this item would be 40%.

When you aggregate this to store level, we will get a figure of how many customers were actually affected (based on the forecast) by the empty shelf.

2. Empty shelf

Number of article lines / products with stock = 0

Empty Shelf = ———————————————- ———————-

Number of article lines / products in the assortment in total

Assortment is defined as what purchasing / category management has decided.

Deviations between what the individual store has in their space program, and the defined assortment for the store may have to be measured with a separate key figure; assortment loyalty.

For the reports, inventory = 0 means that inventory is 0 or less than zero in the store’s systems.

Other priority target measures:

- Correct quantity

- Correct time

- Correct administration

Combined target measures:

- Delivery of Order – Availability

- Complete orders at the right time

- The perfect order

The target measures can be used by both the customer and the supplier for follow-up of each other’s performance.

Prerequisites for target measures and definitions

Measure

In the measurements, the unit of measurement is described as “sales unit».

It is recommended that Stock Keeping Unit (SKU) is used as a sales unit. Stock Keeping Unit (SKU) is established in most systems and is the base for transactions; ex. ordering, delivery, billing etc. to the store.

Consumer Units (CU) as a unit of measurement, however, should be the vision and goal of the future, as the Consumer Unit (CU) is the unit of measurement that is uniform and shared throughout the value chain.

Agreement on measurement of service level

Which target measures to use and what definitions should apply should be anchored in a bilateral agreement.

The agreement can regulate conditions such as:

- Accrual

- Lead times

- Assortment

- Time frame

- How the exchange of measurement results should take place

- Where and when the measurement should take place for the measurement points associated with the priority target measure “Correct time»

- Duration of measurements. In choosing definitions, the parties must agree on the degree of service to be calculated over time or in relation to a contracted number of orders

Definitions – Priority target measures

The target measures are based on three important dimensions in the term «service level»:

- Quantity – availability

- Time – reliability

- Administration – security

The priority targets measures should be followed and evaluated continuously with focus on level, trends and development.

Target measures Correct quantity – availability

The target measure “Correct quantity” measures availability as precision in quantity delivered.

Definition:

| Number of delivered sales Units | = Availability |

| Quantity of ordered sales Units |

The quantity ordered is the amount that the customer initially ordered.

Not delivered quantity represents deviations in delivery.

Target measure At the right time – reliability

The target measure “At the right time” measure reliability as precision in delivery time.

The target measure is used to measure compliance with time limits defined in the agreement between the parties.

The target measure can be used along several dimensions in the value chain.

Examples may be if orders are sent at the right time, if order confirmations are sent at the right time, if delivery is picked up at the right time, if Despatch Advice is sent at the right time, etc.

Definition (with example order):

| Number of late or early delivery orders | = Reliability |

| Total quantity of orders |

Delayed or premature is determined by whether exchange / delivery is within the agreed time frame.

At Incoterms Ex Works delivery terms, the assessment of the supplier’s reliability is on the supplier’s ramp.

The delivery is received when the order / delivery etc., is acknowledged for.

Target measures Correct Administration – Security

The target measure “Proper Administration” measures security as compliance between what is ordered in the order and what has been delivered and has been invoiced, that is, the correct product without errors and with the correct documentation.

Definition:

| Quantity of orders without credit / debit notes | = SAFETY |

| Total quantity of orders |

Correct administration means that Despatch Advice, shipping notes, invoices etc. are complete and error-free in relation to the delivery.

Only credit and debit notes affecting physical delivery are included in the measurement.

The target measure can also be used to measure the quality of orders from the customer.

Examples of calculation of service level for priority target measures can be found in the document

Definitions – Combined target measures

The priority target measures can be combined in different ways, to create Combined target measures.

STAND has defined 3 examples:

Target measure Delivery Order – Availability

The target measure “Delivery Order” gives the proportion of the orders that are properly delivered.

Definition:

| Quantity of complete orders delivered | = Level of Order Delivery |

| Total number of orders ordered |

A complete delivery order contains all ordered sales units, in the correct quantity

Availability will primarily be measured as the priority target measure “Proper Quantity – Availability”, but to calculate the combined measurements below, it is a prerequisite that “Delivery Order – Availability” is calculated.

Complete orders at the right time – Availability & Reliability

The target measure describes both accessibility and reliability in the interaction.

The target measure is composed of the target measures:

- Delivery of Order – Availability

- At the right time – Reliability.

Definition:

| Availability expressed per order

– Quantity of late or early delivery orders |

= Complete orders at the right time |

| Total quantity of orders |

Only one error per. order is counted

The measurement of “Complete Orders at the Right Time” shall be done at the place of arrival. At Incoterms Ex Works delivery terms, this is the supplier’s ramp

The perfect order