Contact

For general questions, contact:

support@stand.no

For supplier specific questions, contact:

Thomas Weihe

Director Value Chain Affairs

Dagligvareleverandørenes forening

thomas.weihe@dlf.no

For retailer specific questions, contact:

Torbjørn Nyberget

Senior Advisor Logistics

Dagligvarehandelens Miljøforum

torbjorn.nyberget@dmf.no

If there is information you are missing or you have problemes navigating on stand.no, please let us know.Send us an email.

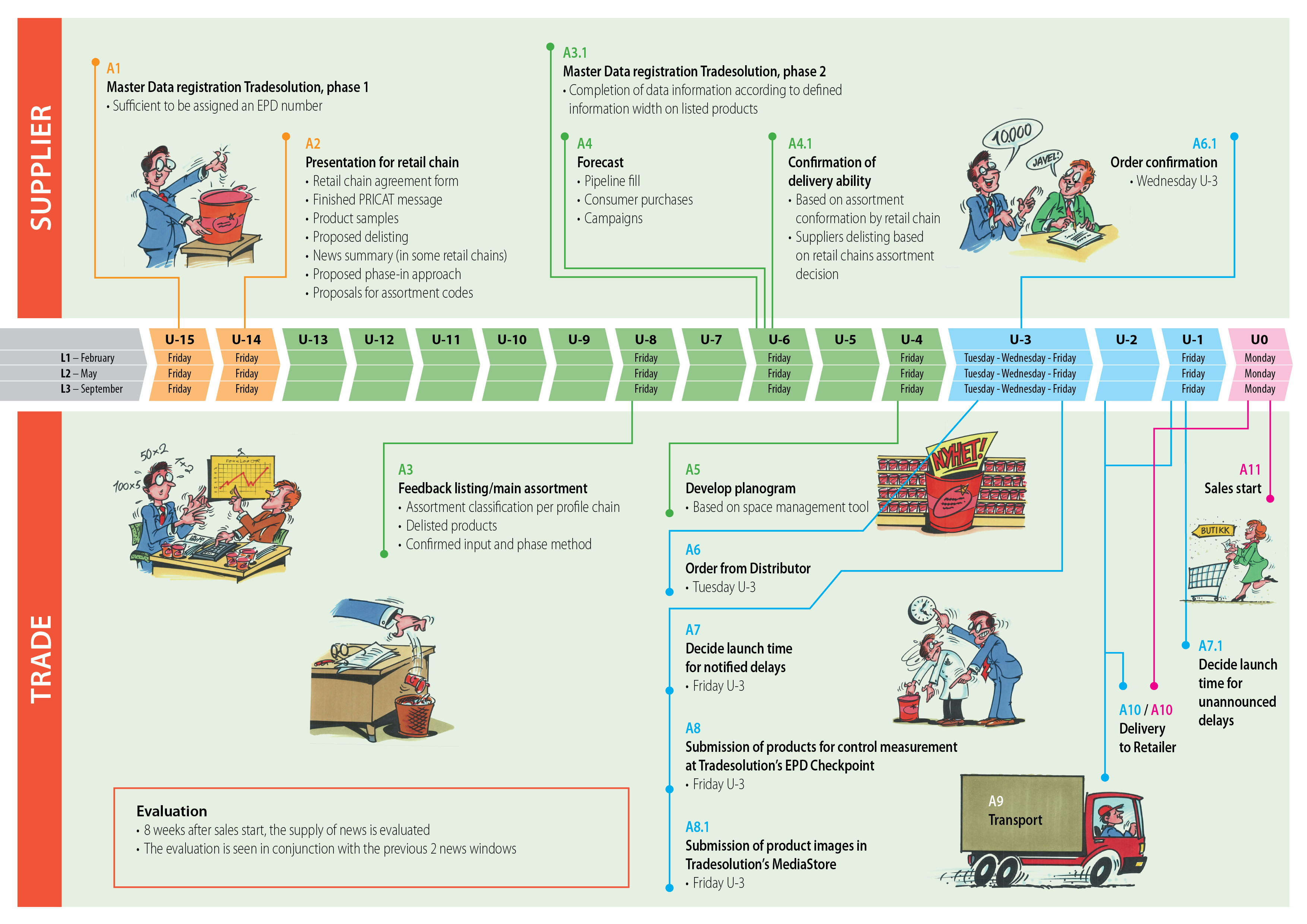

328 Data Sharing

Background

The industry agreement on reducing food waste was signed between the authorities and a unified food industry in June 2017. The goal of the agreement is to halve food waste in Norway by 2030, in line with the UN’s Sustainable Development Goals. A government-appointed Food Waste Committee delivered a report on January 3, 2024, with recommendations for new and enhanced measures to achieve the halving target. One of the recommended measures is standardized and increased data sharing in the value chain. STAND has developed this standard on behalf of the Food Waste Committee.

Purpose

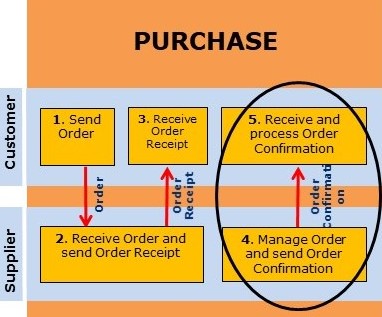

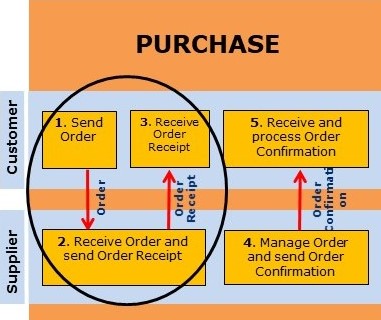

The standard defines the format and exchange frequency for purchase forecasts from wholesalers to suppliers in the grocery industry. The purpose of the standard is to contribute to a significant reduction in food waste, as well as to improve the efficiency of goods and information flow in the industry. Furthermore, the standard aims for continuous improvement. This will be achieved through the exchange of defined KPIs and structured bilateral dialogue. To achieve these goals, it is also assumed that suppliers are capable of sending high-quality order confirmations to wholesalers. This means order confirmation down to the product line level and that the stated volume/quantity of products can be delivered at the desired delivery time. Regarding the exchange of other types of information between wholesalers and suppliers, such as the wholesaler’s sales to stores, POS data in stores, and inventory levels, this can be exchanged. This type of exchange is agreed upon and implemented bilaterally.

Scope

- The standard covers purchase forecasts from wholesalers to suppliers in the grocery industry. This means that direct distribution from suppliers to stores is not included in this standard.

- The purchase forecasts include grocery trade, kiosks, gas stations, convenience stores, and HoReCa (hotel, restaurant, and catering).

- The purchase forecasts from wholesalers are aggregated, i.e., total figures per wholesaler (chain).

- Purchase forecasts are specified uniformly for all product types and product shelf life. This means that all product categories and shelf life are treated equally in the standard.

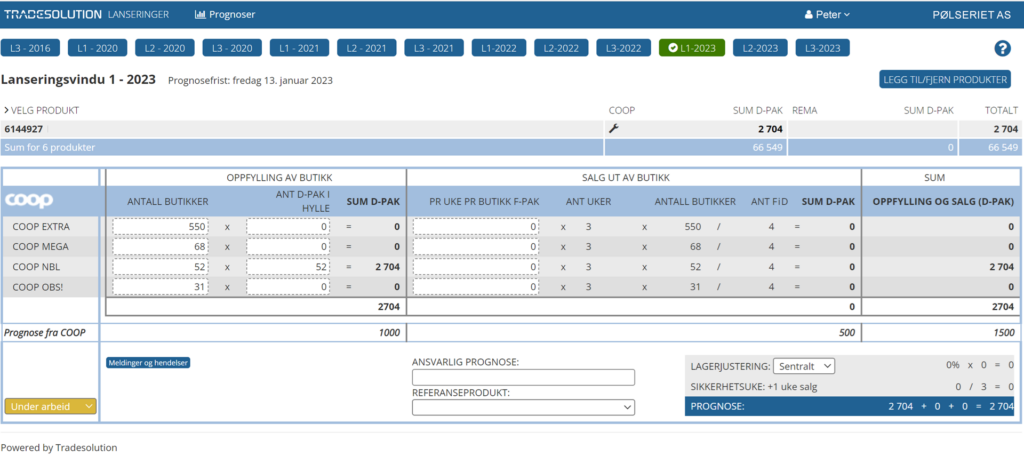

- Purchase forecasts are provided at the article level, i.e., (SKU). The time horizon for purchase forecasts: The time horizon refers to the period up to the date the wholesaler retrieves the goods from the supplier (ex works).

- Part A: The forecast horizon is 13 weeks ahead. A purchase forecast from wholesaler to supplier must be provided for each week. This is given as a sum on a weekly basis.

- Part B: For the next three weeks, i.e., U-1, U-2, and U-3, purchase forecasts must be provided daily.

The purchase forecasts sent by the wholesaler to the supplier include:

a) Normal Sales: New products, phase-outs, and assortment changes should be included in the purchase forecast for normal sales. For new products, a clear distinction must be made between forecasts and orders.

b) Campaign Forecasts: Purchase forecasts for campaigns are included in the figures from wholesaler to supplier along with purchase forecasts for normal sales. To inform about purchase forecasts for campaigns, such as volume, it is recommended to exchange additional information between wholesaler and supplier. Note the handling of pre-orders. A pre-order means a physical order from the wholesaler to the supplier. The wholesaler has already sent the order. This should not be part of the purchase forecast.

c) Seasonal Products: Seasonal products are defined in STAND as “a product sold in a time-limited period related to a season defined by the parties involved.” A distinction is made here between seasonal products and contract sales. Seasonal products are characterized by being ordered from the wholesaler and delivered by the supplier continuously throughout the season. Seasonal products are included in the normal purchase forecast from wholesaler to supplier. Contract sales are characterized by an agreement being made for each product between the wholesaler and the supplier. For contract sales, a volume of the product to be delivered by the supplier to the wholesaler is locked in. Suppliers do not need purchase forecasts for contract sales. However, since no order has been sent from the wholesaler to the supplier, the contract sale for this product will appear as part of the purchase forecast sent by the wholesaler to the supplier. The supplier will then disregard the purchase forecast for these products

Exchange Frequency

The exchange frequency for purchase forecasts is weekly. More frequent exchanges can be agreed upon bilaterally for U-1, U-2, and U-3.

Exchange Format

Purchase forecasts from wholesaler to supplier are sent in Excel file format from wholesaler to supplier. The files are sent via email. There is no need for explicit identification of wholesaler and supplier in these emails. The emails are sent from/to email addresses that have been agreed upon in advance.

Two different files should be exchanged:

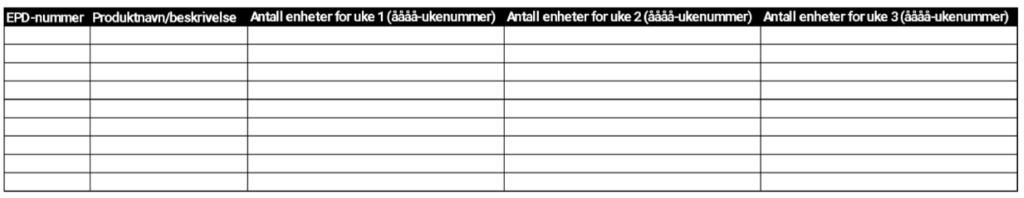

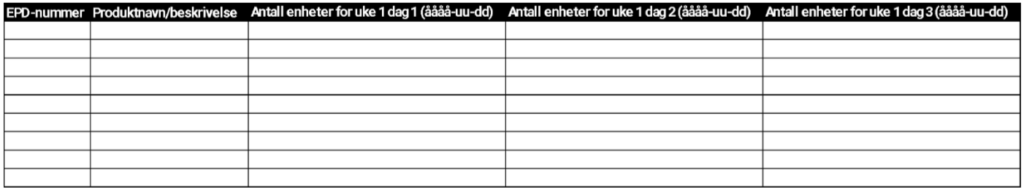

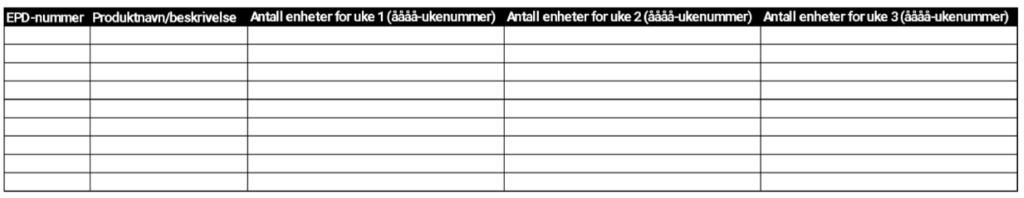

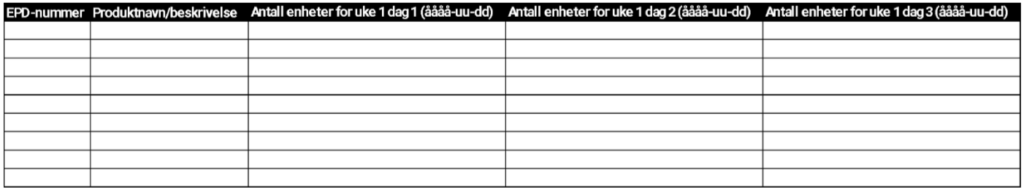

a. File A contains purchase forecasts per week for weeks 1 – 13. Column headers are EPD number, product description, number of units for the week number (year + calendar week).

b. File B contains purchase forecasts per day for the next three weeks (U–1, U–2, and U–3). Column headers are EPD number, product description, number of units per day that the wholesaler retrieves from the supplier.

The content in the Excel sheets is specified as follows:

EPD number (File A and File B) identifies the ordering unit (D-pack) from wholesaler to supplier. See https://tradesolution.no/tjenester/epd/. Here, the EPD number is defined with 8 digits. Product name/description: It is recommended to use the same description as registered in the EPD database. Length is up to 30 alphanumeric characters.

Number of units per week: This refers to the number of ordering units (D-pack), unless otherwise agreed between the parties. Here, the number of units of the EPD number in the purchase forecast for weeks 1 – 13 is recorded. The week number is indicated with “year-week number” in the format “yyyy-ww” from week 1 to 13. There are 13 columns allocated.

Number of units per day: This refers to the number of ordering units (D-pack), unless otherwise agreed between the parties. Here, the number of units of the EPD number in the daily purchase forecast that the wholesaler retrieves from the supplier for the next three weeks U-1, U-2, U-3 is recorded. The day is indicated with year-month-day in the format “yyyy-mm-dd”. There are 15 columns allocated.

Continuous Improvement

To measure the effect of measures and ensure continuous improvement, relevant KPIs should be exchanged between the parties.

Primary KPI is forecast deviation – purchase forecast from wholesaler to supplier – to be exchanged

Forecast deviation is defined here as the purchase forecast from wholesaler to supplier measured against the actual order from wholesaler to supplier per D-pack (SKU). Frequency can vary. Goals and thresholds/limits are agreed upon bilaterally. Both parties measure forecast deviation and exchange this in ongoing dialogue, as outlined in the section on Regular Bilateral Dialogue below.

Download example 1

Download example 2

Remaining shelf life in % – to be exchanged

One of the main goals of this standard is to contribute to reduced food waste. Various factors influence the development of food waste. The industry assumes that increased remaining shelf life through the value chain generally contributes to reduced food waste, and that measuring changes in remaining shelf life will therefore be a relevant indicator. See Plan and prepare for a production

Further definition is under development and will be added to the standard.

Other KPIs – Recommended to be exchanged:

Service Level: Service level is a common KPI in the grocery industry. Refer to the definition in STAND. Of these definitions, the following is recommended: Number of delivered sales units / number of ordered sales units from supplier to wholesaler. Here, sales units refer to D-pack (SKU). Measurement and exchange are agreed upon bilaterally.

Regular Bilateral Dialogue

The exchange and evaluation of relevant KPIs are part of the bilateral dialogue between the chain/wholesaler and the supplier. The industry has a clear ambition to enhance this dialogue. It is important to establish bilateral platforms where chains and their suppliers can align mutual expectations and results. If such a platform is not already established, both parties may initiate an agreement to set this up, with responsibility lying with the wholesaler. The platform should be established for all suppliers, large and small. Meetings can be physical or digital. The dialogue should be regular, but the frequency will vary based on both parties’ needs. It is assumed that relevant functions with sufficient decision-making authority from both sides will participate.

Data Sharing

Background

The industry agreement on reducing food waste was signed between the authorities and a unified food industry in June 2017. The goal of the agreement is to halve food waste in Norway by 2030, in line with the UN’s Sustainable Development Goals. A government-appointed Food Waste Committee delivered a report on January 3, 2024, with recommendations for new and enhanced measures to achieve the halving target. One of the recommended measures is standardized and increased data sharing in the value chain. STAND has developed this standard on behalf of the Food Waste Committee.

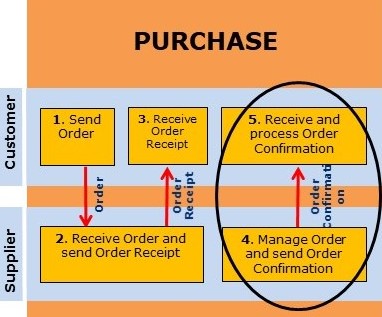

Purpose

The standard defines the format and exchange frequency for purchase forecasts from wholesalers to suppliers in the grocery industry. The purpose of the standard is to contribute to a significant reduction in food waste, as well as to improve the efficiency of goods and information flow in the industry. Furthermore, the standard aims for continuous improvement. This will be achieved through the exchange of defined KPIs and structured bilateral dialogue. To achieve these goals, it is also assumed that suppliers are capable of sending high-quality order confirmations to wholesalers. This means order confirmation down to the product line level and that the stated volume/quantity of products can be delivered at the desired delivery time. Regarding the exchange of other types of information between wholesalers and suppliers, such as the wholesaler’s sales to stores, POS data in stores, and inventory levels, this can be exchanged. This type of exchange is agreed upon and implemented bilaterally.

Scope

- The standard covers purchase forecasts from wholesalers to suppliers in the grocery industry. This means that direct distribution from suppliers to stores is not included in this standard.

- The purchase forecasts include grocery trade, kiosks, gas stations, convenience stores, and HoReCa (hotel, restaurant, and catering).

- The purchase forecasts from wholesalers are aggregated, i.e., total figures per wholesaler (chain).

- Purchase forecasts are specified uniformly for all product types and product shelf life. This means that all product categories and shelf life are treated equally in the standard.

- Purchase forecasts are provided at the article level, i.e., (SKU). The time horizon for purchase forecasts: The time horizon refers to the period up to the date the wholesaler retrieves the goods from the supplier (ex works).

- Part A: The forecast horizon is 13 weeks ahead. A purchase forecast from wholesaler to supplier must be provided for each week. This is given as a sum on a weekly basis.

- Part B: For the next three weeks, i.e., U-1, U-2, and U-3, purchase forecasts must be provided daily.

The purchase forecasts sent by the wholesaler to the supplier include:

a) Normal Sales: New products, phase-outs, and assortment changes should be included in the purchase forecast for normal sales. For new products, a clear distinction must be made between forecasts and orders.

b) Campaign Forecasts: Purchase forecasts for campaigns are included in the figures from wholesaler to supplier along with purchase forecasts for normal sales. To inform about purchase forecasts for campaigns, such as volume, it is recommended to exchange additional information between wholesaler and supplier. Note the handling of pre-orders. A pre-order means a physical order from the wholesaler to the supplier. The wholesaler has already sent the order. This should not be part of the purchase forecast.

c) Seasonal Products: Seasonal products are defined in STAND as “a product sold in a time-limited period related to a season defined by the parties involved.” A distinction is made here between seasonal products and contract sales. Seasonal products are characterized by being ordered from the wholesaler and delivered by the supplier continuously throughout the season. Seasonal products are included in the normal purchase forecast from wholesaler to supplier. Contract sales are characterized by an agreement being made for each product between the wholesaler and the supplier. For contract sales, a volume of the product to be delivered by the supplier to the wholesaler is locked in. Suppliers do not need purchase forecasts for contract sales. However, since no order has been sent from the wholesaler to the supplier, the contract sale for this product will appear as part of the purchase forecast sent by the wholesaler to the supplier. The supplier will then disregard the purchase forecast for these products

Exchange Frequency

The exchange frequency for purchase forecasts is weekly. More frequent exchanges can be agreed upon bilaterally for U-1, U-2, and U-3.

Exchange Format

Purchase forecasts from wholesaler to supplier are sent in Excel file format from wholesaler to supplier. The files are sent via email. There is no need for explicit identification of wholesaler and supplier in these emails. The emails are sent from/to email addresses that have been agreed upon in advance.

Two different files should be exchanged:

a. File A contains purchase forecasts per week for weeks 1 – 13. Column headers are EPD number, product description, number of units for the week number (year + calendar week).

b. File B contains purchase forecasts per day for the next three weeks (U–1, U–2, and U–3). Column headers are EPD number, product description, number of units per day that the wholesaler retrieves from the supplier.

The content in the Excel sheets is specified as follows:

EPD number (File A and File B) identifies the ordering unit (D-pack) from wholesaler to supplier. See https://tradesolution.no/tjenester/epd/. Here, the EPD number is defined with 8 digits. Product name/description: It is recommended to use the same description as registered in the EPD database. Length is up to 30 alphanumeric characters.

Number of units per week: This refers to the number of ordering units (D-pack), unless otherwise agreed between the parties. Here, the number of units of the EPD number in the purchase forecast for weeks 1 – 13 is recorded. The week number is indicated with “year-week number” in the format “yyyy-ww” from week 1 to 13. There are 13 columns allocated.

Number of units per day: This refers to the number of ordering units (D-pack), unless otherwise agreed between the parties. Here, the number of units of the EPD number in the daily purchase forecast that the wholesaler retrieves from the supplier for the next three weeks U-1, U-2, U-3 is recorded. The day is indicated with year-month-day in the format “yyyy-mm-dd”. There are 15 columns allocated.

Continuous Improvement

To measure the effect of measures and ensure continuous improvement, relevant KPIs should be exchanged between the parties.

Primary KPI is forecast deviation – purchase forecast from wholesaler to supplier – to be exchanged

Forecast deviation is defined here as the purchase forecast from wholesaler to supplier measured against the actual order from wholesaler to supplier per D-pack (SKU). Frequency can vary. Goals and thresholds/limits are agreed upon bilaterally. Both parties measure forecast deviation and exchange this in ongoing dialogue, as outlined in the section on Regular Bilateral Dialogue below.

Download example 1

Download example 2

Remaining shelf life in % – to be exchanged

One of the main goals of this standard is to contribute to reduced food waste. Various factors influence the development of food waste. The industry assumes that increased remaining shelf life through the value chain generally contributes to reduced food waste, and that measuring changes in remaining shelf life will therefore be a relevant indicator. See Plan and prepare for a production

Further definition is under development and will be added to the standard.

Other KPIs – Recommended to be exchanged:

Service Level: Service level is a common KPI in the grocery industry. Refer to the definition in STAND. Of these definitions, the following is recommended: Number of delivered sales units / number of ordered sales units from supplier to wholesaler. Here, sales units refer to D-pack (SKU). Measurement and exchange are agreed upon bilaterally.

Regular Bilateral Dialogue

The exchange and evaluation of relevant KPIs are part of the bilateral dialogue between the chain/wholesaler and the supplier. The industry has a clear ambition to enhance this dialogue. It is important to establish bilateral platforms where chains and their suppliers can align mutual expectations and results. If such a platform is not already established, both parties may initiate an agreement to set this up, with responsibility lying with the wholesaler. The platform should be established for all suppliers, large and small. Meetings can be physical or digital. The dialogue should be regular, but the frequency will vary based on both parties’ needs. It is assumed that relevant functions with sufficient decision-making authority from both sides will participate.

Videos

132 Allocation of total shelf life on a product

Allocation of total shelf life on a product

Reducing food waste is an overall goal in society. Food waste related to exceeding the limit values of shelf life between the parties in the value chain, constitutes a significant part.

Surveys shows that food waste are significantly reduced if the store and the consumer have a larger part of the total shelf life.

It is therefore a goal that the producer and distributor consume the least amount of available time and that the maximum amount of time is exposed to the consumer.

The grocery industry has defined one Table for allocation of shelf life of a product which regulates the responsibility for and expectations the recipient of products has, linked to shelf life. Online players with b2c sales will be defined as retailers when dividing total shelf life.

In case of minor exceedances of the table’s limit values, participants are expected to seek solutions that provide the lowest possible food waste.

The parties are encouraged to develop performance and collaborate to reduce consumption of shelf life.

173 The Modular system

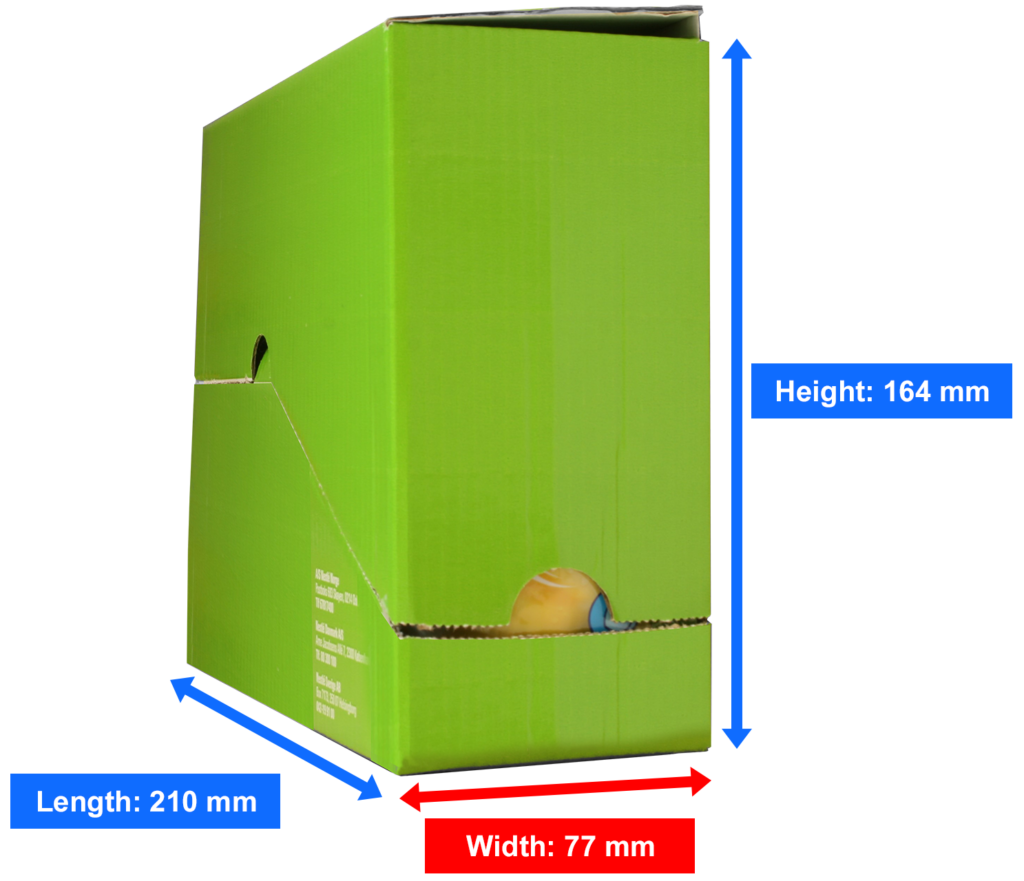

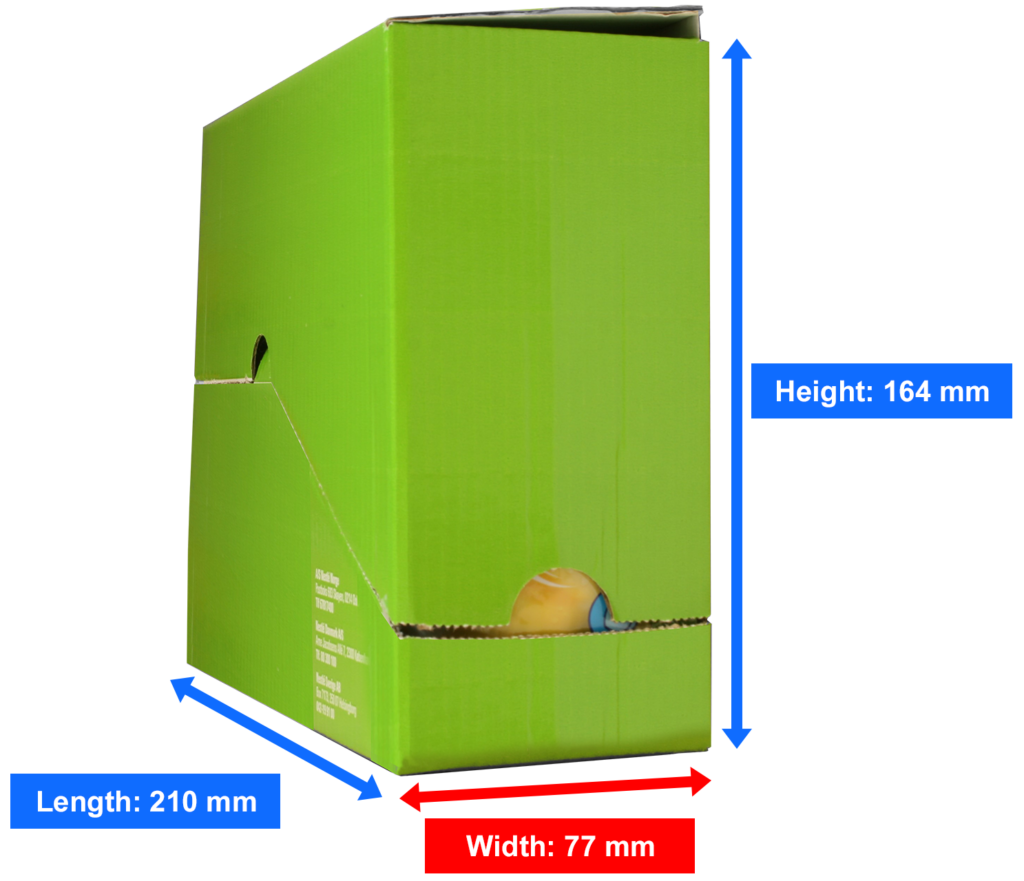

To ensure efficient utilization of production facilities, transport, storage and retail systems, etc., all packaging levels – Consumer Units (CU), Stock Keeping Units (SKU) and Distribution Units (DU) must be adapted to the modular system.

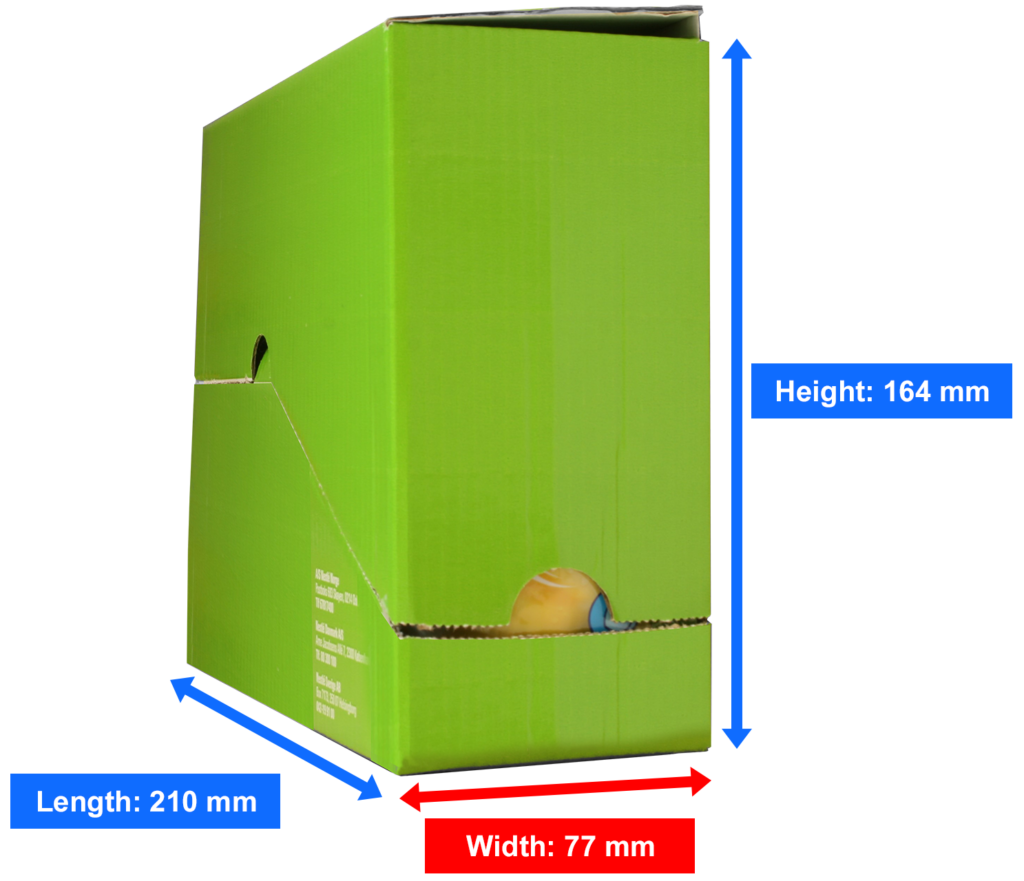

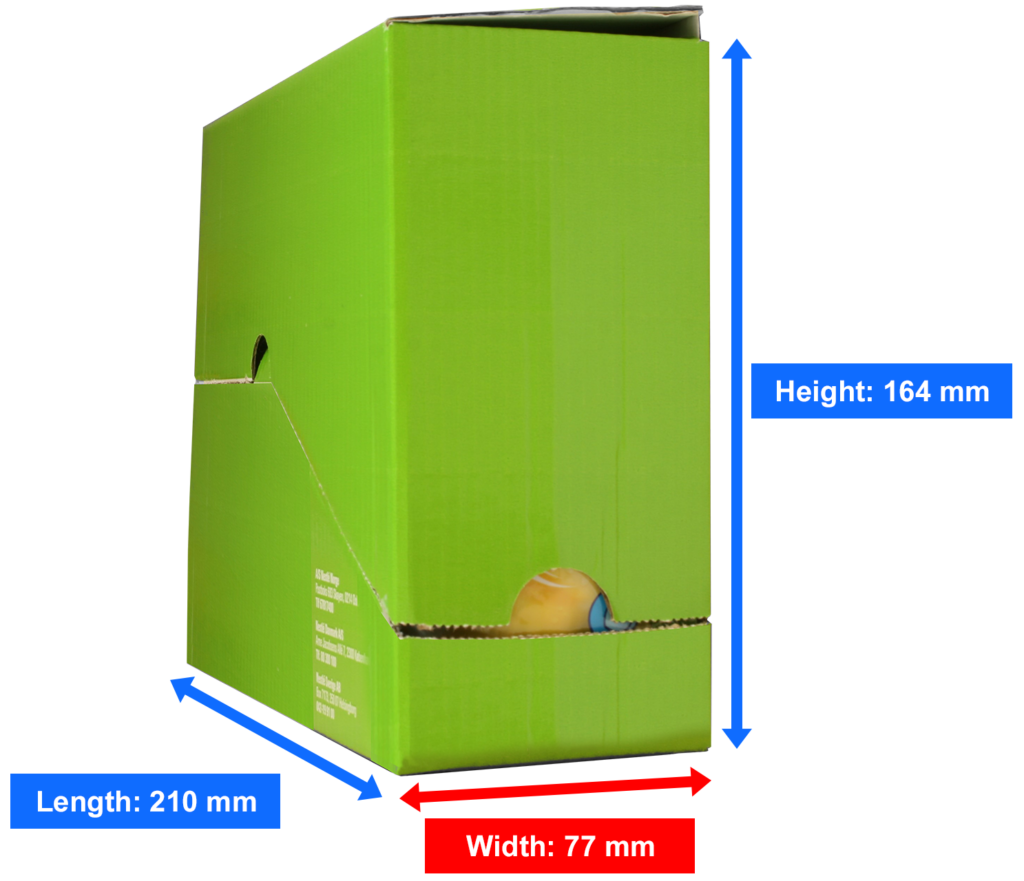

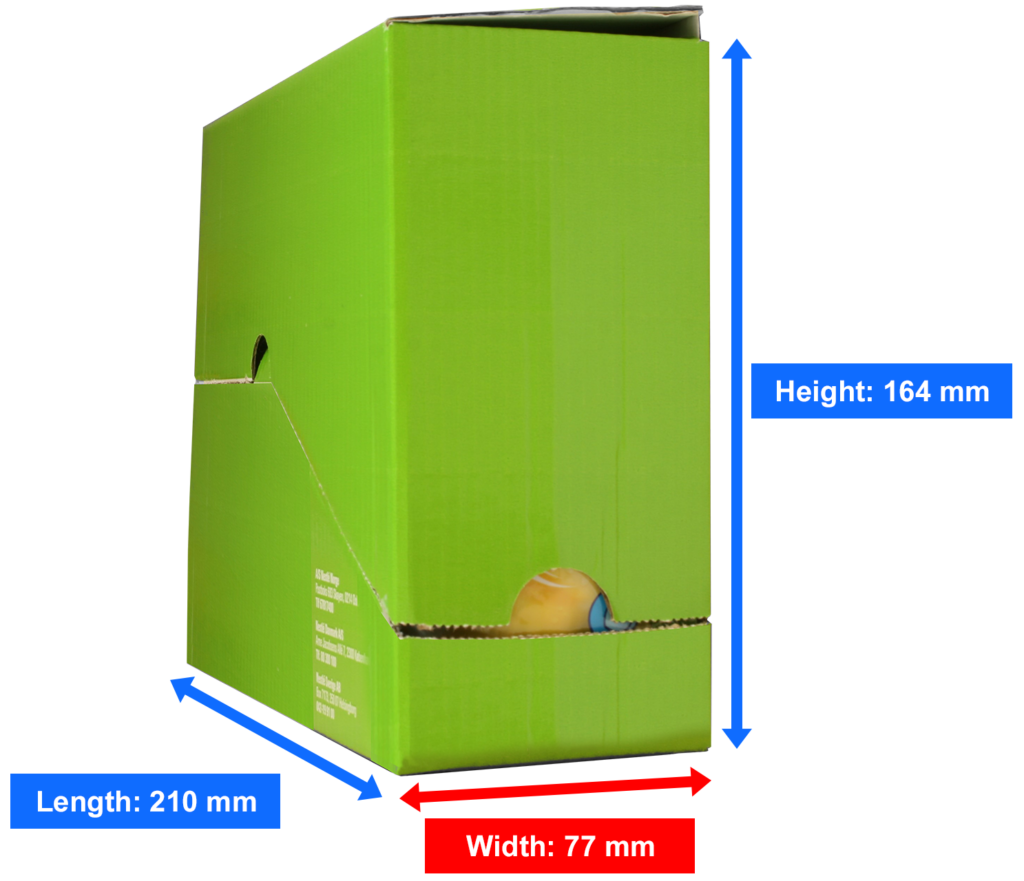

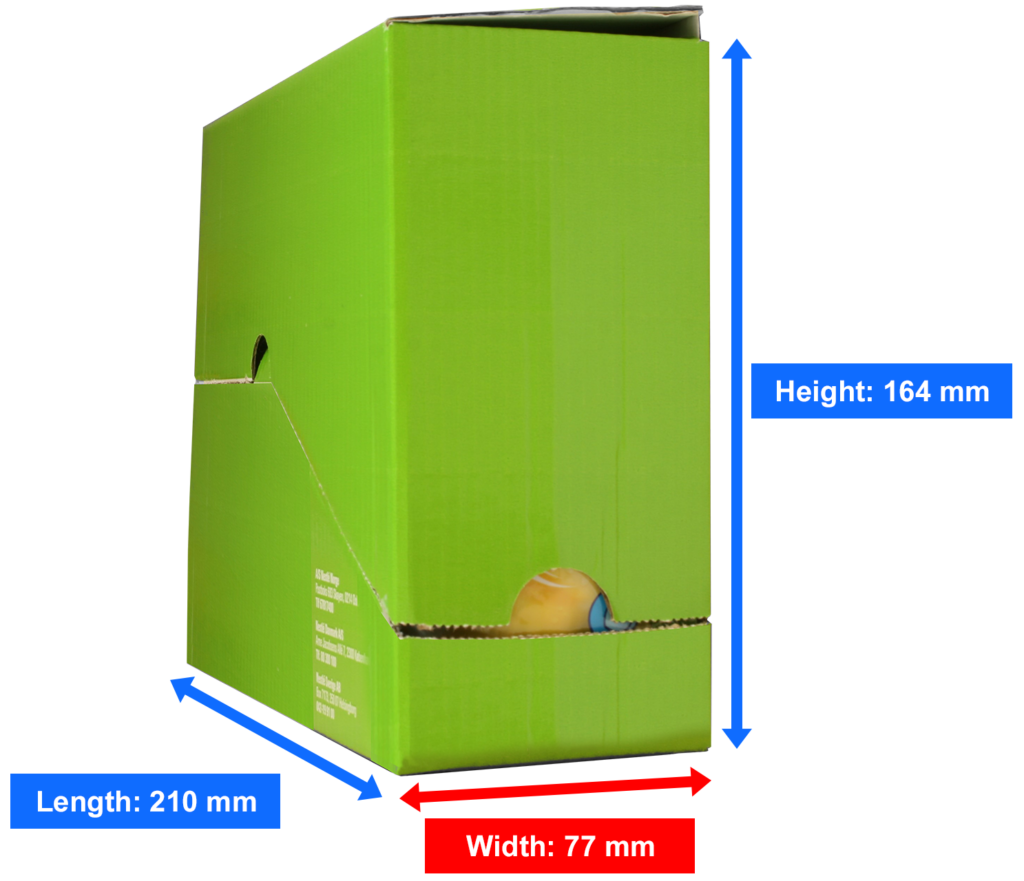

The modular system is based on physical goals; length, width and height.

The starting point for the modular system is a Basic module.

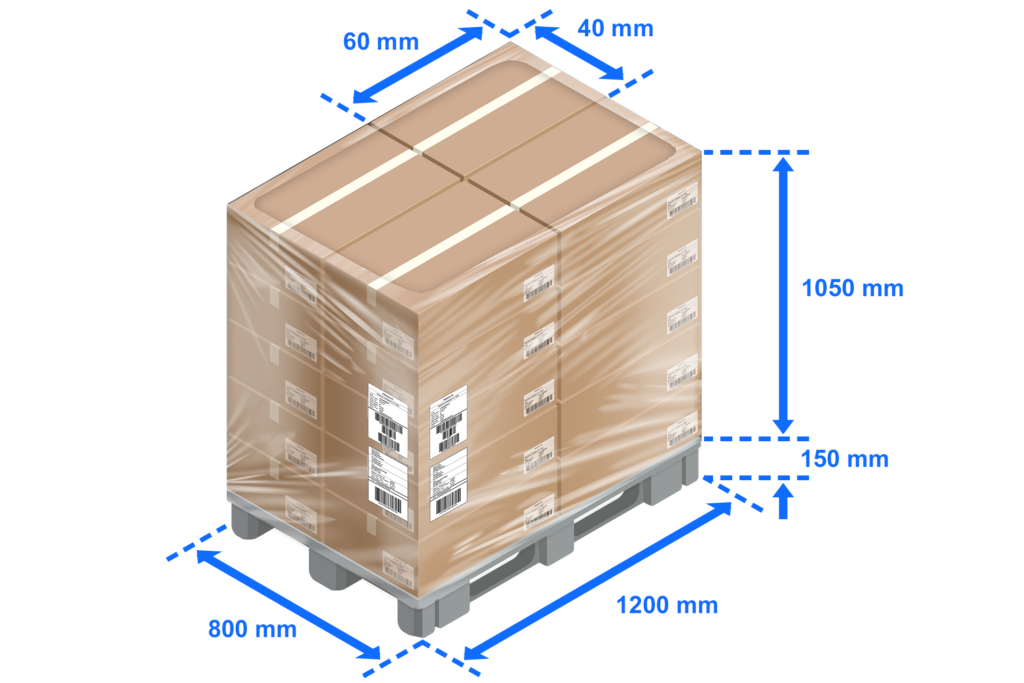

This has the dimensions; 600 mm * 400 mm and must be adjusted to a height as one Standard pallet (this amounts to 1050 mm ex. pallet, 1200 mm incl. pallet.

When optimizing an existing product, a deviation of a maximum of 49 mm is allowed.

This allows a total height including pallet of 1249 mm.

All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers.

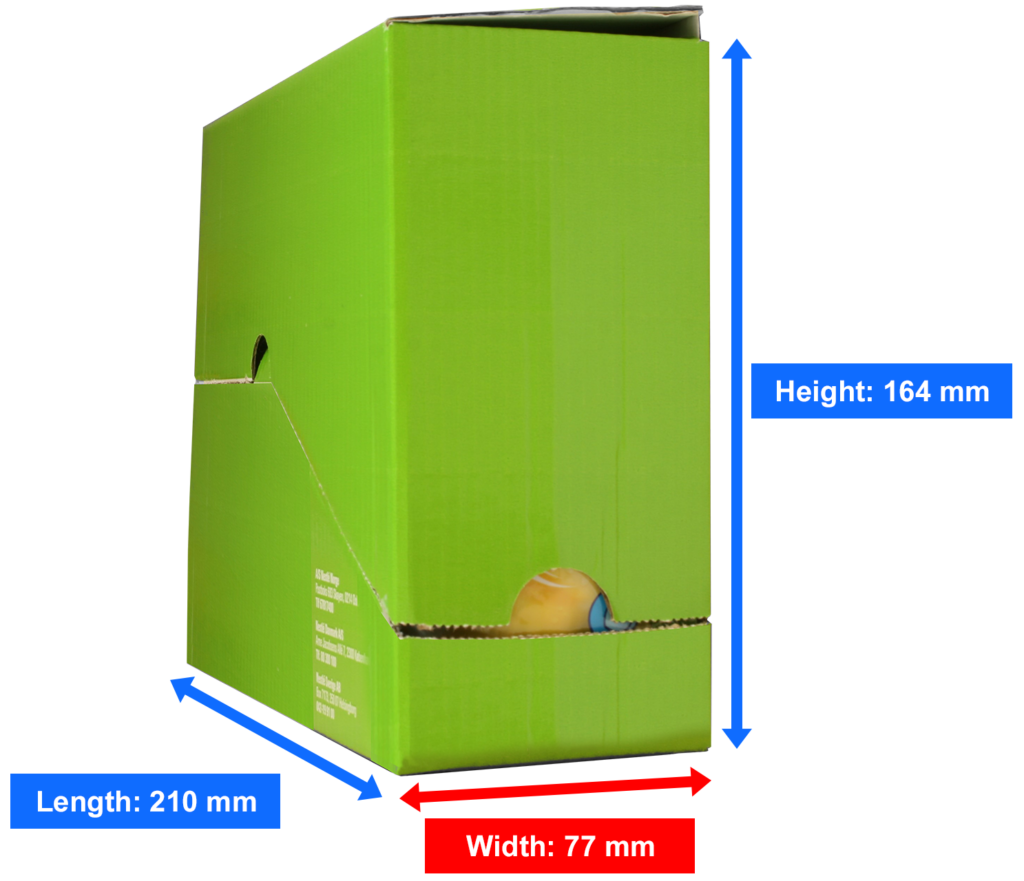

Example of optimized pallet with base module 600 x 400 mm

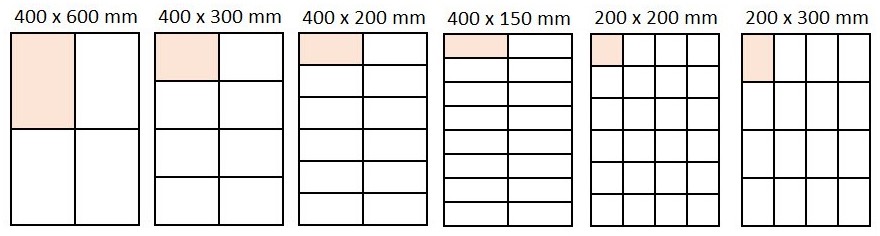

Examples of sizes that are widely used on Stock Keeping Units (SKU), and which are customized to basic modules

175 Requirements for the design of the Distribution Unit (DU) and palletization

Requirements for the design of the Distribution Unit (DU) and palletization

The Distribution Unit (DU) is the unit the Stock Keeping Units (SKU) is stacked on / packed in for transport to distributor.

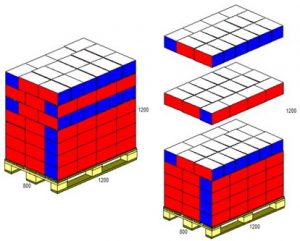

Design of a Standard pallet (Standard pallet and Standard pallet – Low)

A Standard pallet must contain the same product (same GTIN) with a fixed number of Stock Keeping Units (SKU), in a fixed pallet pattern, with equal number of Stock Keeping Units (SKU)on each layer, and where labelling of unique product information on the Distribution Unit (DU) is possible.

The pallet structure shall contain as little excess volume of “air” as possible.

Standard pallet

Maximum pallet height must be 1200 mm incl. pallet. All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers.

Tolerance limit for existing products is 1249 mm.

Standard pallet – Low

Maximum pallet height shall be 600 mm incl. pallet.

Standard pallet – Low is used for low-frequency products and for products with short shelf life.

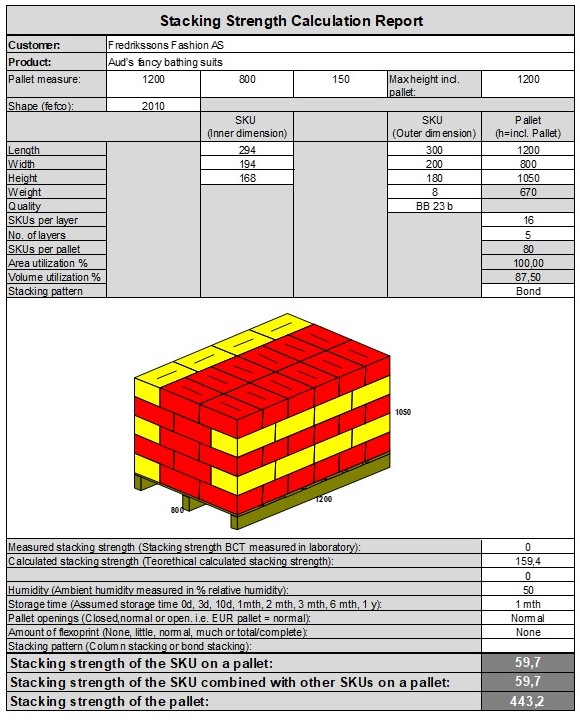

Principles for the construction of a palletpattern, central in calculation of top load weight, ref Top load labelling system.

When creating a pallet pattern, the following applies:

- A packaged Distribution Unit (DU) must be form stable and handling-friendly

- A Distribution Unit (DU) shall withstand regular transport, handling and storage through the value chain

- For single article Distribution Units (DU), all layers must contain the same number of Stock Keeping Units (SKU), and in a fixed pallet pattern

- Requirements for equal number of Stock Keeping Units (SKU) on each pallet / identical layer from pallet to pallet, with the possibility of variation between the layers

- The pallet should not have overhang

- The Stock Keeping Unit (SKU) should be placed on the pallet as it is exposed in the store

- Do not glue between pallet layers or between Stock Keeping Units (SKU) in the same pallet layer

- If a transport label or product label is attached directly to Stock Keeping Unit (SKU), the label must not overlap between 2 Stock Keeping Units (SKUs), either horizontally or vertically

- All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers.

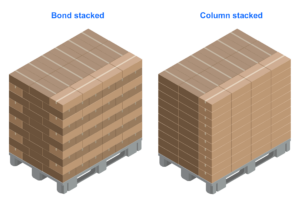

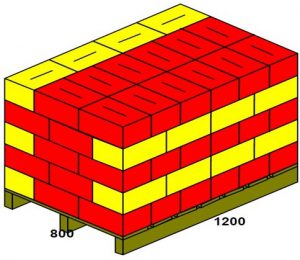

Types of pallet pattern

When constructing Distribution Units (DU), the Stock Keeping Unit (SKU) must be placed in accordance with a given pallet pattern. These are referred to as bond stacking and column stacking. Pallets can also be built as a combination of bond stacking and column stacking.

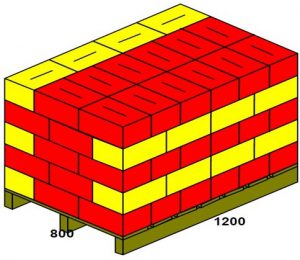

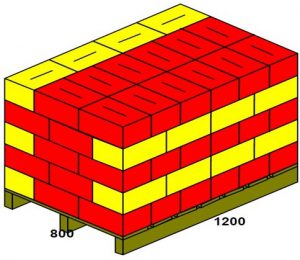

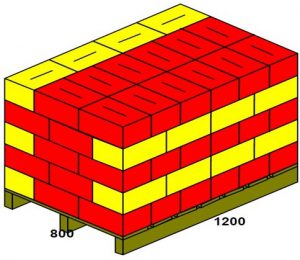

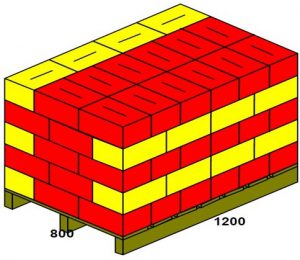

Bond Stacking

Bond Stacking means that the units on every other layer are different, thus locking each other to a greater or lesser extent, but it reduces the compressive strength by approx. 40%.

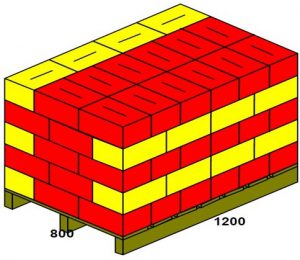

Example of good pallet utilization and stacking with bond stacking, for good stability.

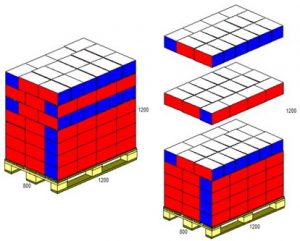

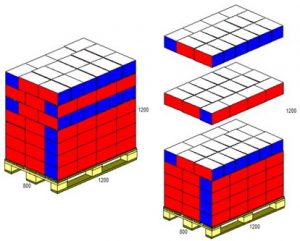

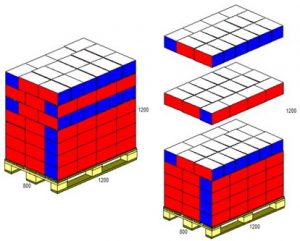

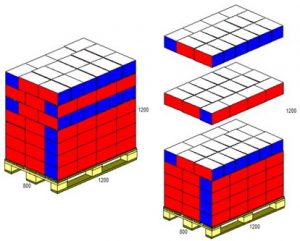

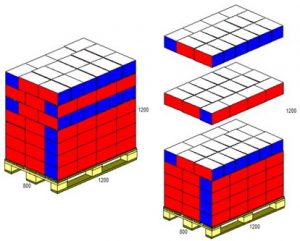

Column Stacking

Column stacking means stacking packages on top of each other without overlapping with other packages. This form of stacking gives maximum strength in terms of pressure load due to that the corners have better roll stiffness than the sides, but the stack gives poor stability without additional use of shrink wrap, strap, ribbon or similar.

Example of column stacking in the lower pallet layers, and bond stacking on the top layer. Combining the different stacking methods achieves good stack strength on the lower layers while the pallet is locked on top.

This is often a good alternative to intermediate pallet sheets.

Use of plastic to secure the pallet through the value chain

- Shrink / stretch film must not be so tight that the packages are deformed

- Shrink / stretch film must be tight around to the pallet

- No tail of plastic must hang loose

- Shrink / stretch film must not cover the fork lift openings on the pallet

- Shrink / stretch film must not be fastened around the pallet blocks

Use of intermediate pallet sheets

Intermediate pallet sheets must be minimized and used only if this is necessary to ensure quality and transportability of the pallet.

Intermediate pallet sheets are preferred if the alternative to this is intermediate cartons, “Ears” on the Stock Keeping Unit (SKU) or use of corner trims.

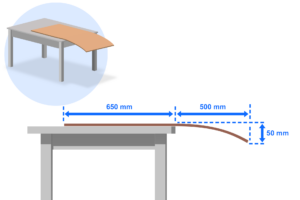

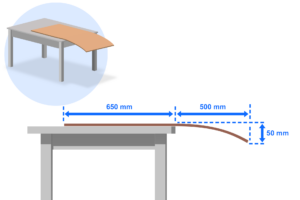

Where intermediate pallet sheets are used, the following requirements apply:

- The pallet sheet to be used for standard euro pallet should have dimensions of 750 mm * 1150 mm, ie 50 mm less than the length and width of the current load carrier

- The pallet sheet must be of rigid cardboard or corrugated cardboard.

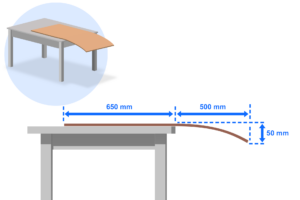

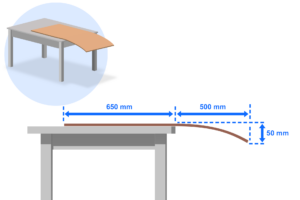

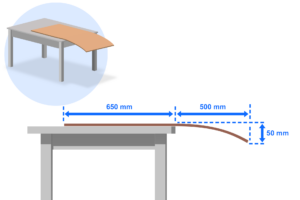

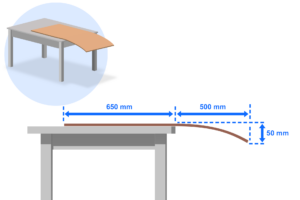

- The stiffness of the pallet sheet must pass the following test: If the short edge of the plate hangs 500 mm from a flat surface (eg a table), the pallet sheet must not bend down more than 50 mm, see illustration below

- No more than one intermediate pallet sheet between each layer

- The intermediate pallet sheet must not be fastened and be flat

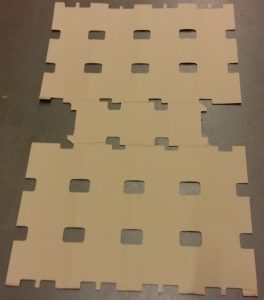

- Only a whole intermediate pallet sheet, i.e. without holes or perforations, shall be used

- In case of questions, one is encouraged to contact the packaging supplier

See also Automated storage at distributor – greater understanding of the depalletization process

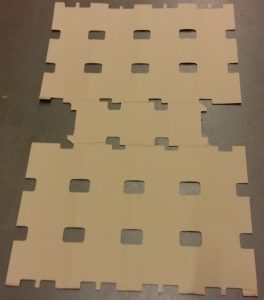

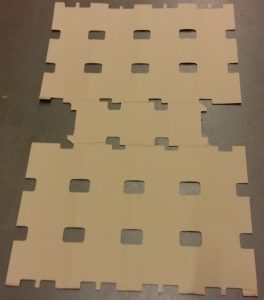

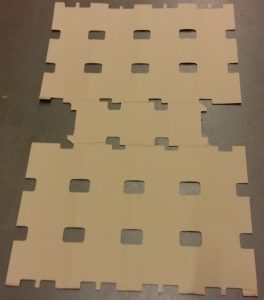

Example of intermediate pallet sheet that does not meet quality requirements. The intermediate pallet sheet is a thin paper and is not suitable for automatic warehouse systems

Example of what happens when using “thin paper” intermediate pallet sheets.

The sheet is hanging down in the robot. It blocks for sensors that check that the layer is separated from the rest of the pallet. The robot will stop, and manual error correction must be carried out before the machine can be restarted.

Example of pallet with intermediate pallet sheets, too big – hanging on outside the pallet.

Is not suitable.

Intermediate pallet sheets with holes. Is not suitable.

156 Definitions – Combined target measures

Definitions – Combined target measures

The priority target measures can be combined in different ways, to create Combined target measures.

STAND has defined 3 examples:

Target measure Delivery Order – Availability

The target measure “Delivery Order” gives the proportion of the orders that are properly delivered.

Definition:

| Quantity of complete orders delivered | = Level of Order Delivery |

| Total number of orders ordered |

A complete delivery order contains all ordered sales units, in the correct quantity

Availability will primarily be measured as the priority target measure “Proper Quantity – Availability”, but to calculate the combined measurements below, it is a prerequisite that “Delivery Order – Availability” is calculated.

Complete orders at the right time – Availability & Reliability

The target measure describes both accessibility and reliability in the interaction.

The target measure is composed of the target measures:

- Delivery of Order – Availability

- At the right time – Reliability.

Definition:

| Availability expressed per order

– Quantity of late or early delivery orders |

= Complete orders at the right time |

| Total quantity of orders |

Only one error per. order is counted

The measurement of “Complete Orders at the Right Time” shall be done at the place of arrival. At Incoterms Ex Works delivery terms, this is the supplier’s ramp

The perfect order

This is the most demanding target measure and measures all types of deviations regarding complete orders.

The target measure is composed of three previously defined target measures:

- Delivery of Order – Availability

- At the right time – reliability

- Correct administration – Security

Definition:

| Quantity of complete orders delivered

– late or early delivery orders – Orders with missing or incorrect documents – Orders with credit / debit notes |

= The perfect order |

| Total quantity of orders |

Only one error per. order is counted

If both the supplier and the customer’s obligations are considered in the target measure, the target measure represents the performance that the parties create in common.

Examples of calculation of service level for combined target measures can be found in the document

Examples of combined target measures

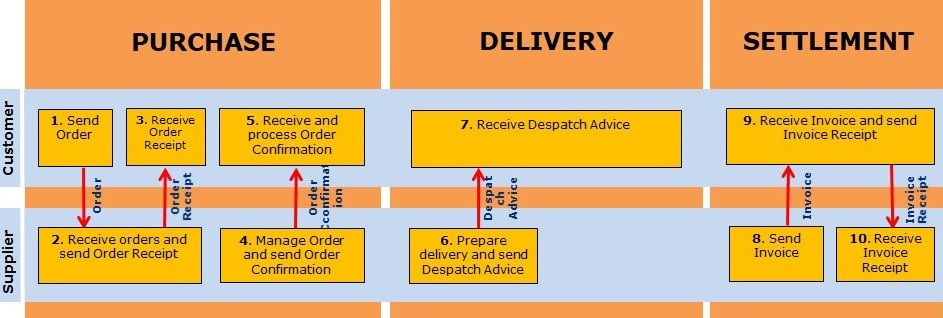

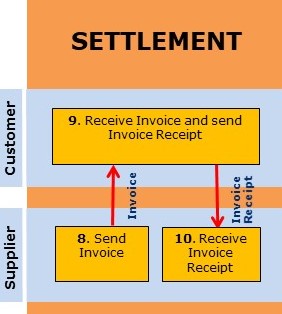

185 Communication and data exchange

The supplier and the retail chain shall keep each other updated in all circumstances that may be relevant for successful assortment change.

Sales and inventory data are made available as soon as they can be communicated.

Target measures

Service Level – for wholesaler and retailer – are measured and exchanged.

For definition of service level refer to Service level – Purpose, types of target measures and assumptions with any clarifications in the retail chain / supplier agreement.

In case of significant deviations in service levels, assortment coding and forecasts are therefore natural reference points.

184 Routine for delays from supplier / Private label

Routine for delays from supplier / Private label

Any delay must be notified immediately with the information available at the time of notification. Message must be sent to the department of category /purchase and the department of logistics.

In case of delay, a distinction is made between notified and unannounced.

Read more about:

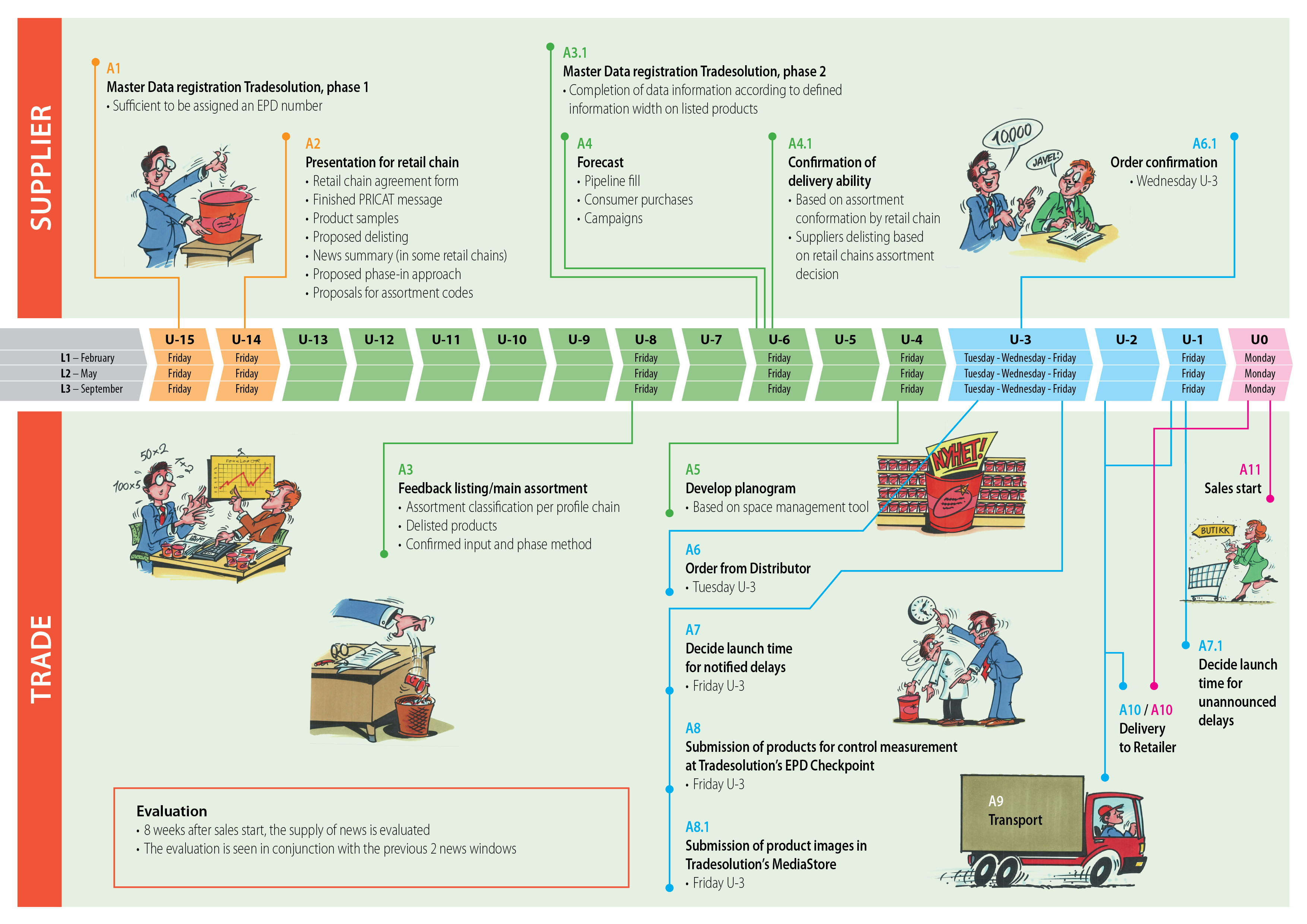

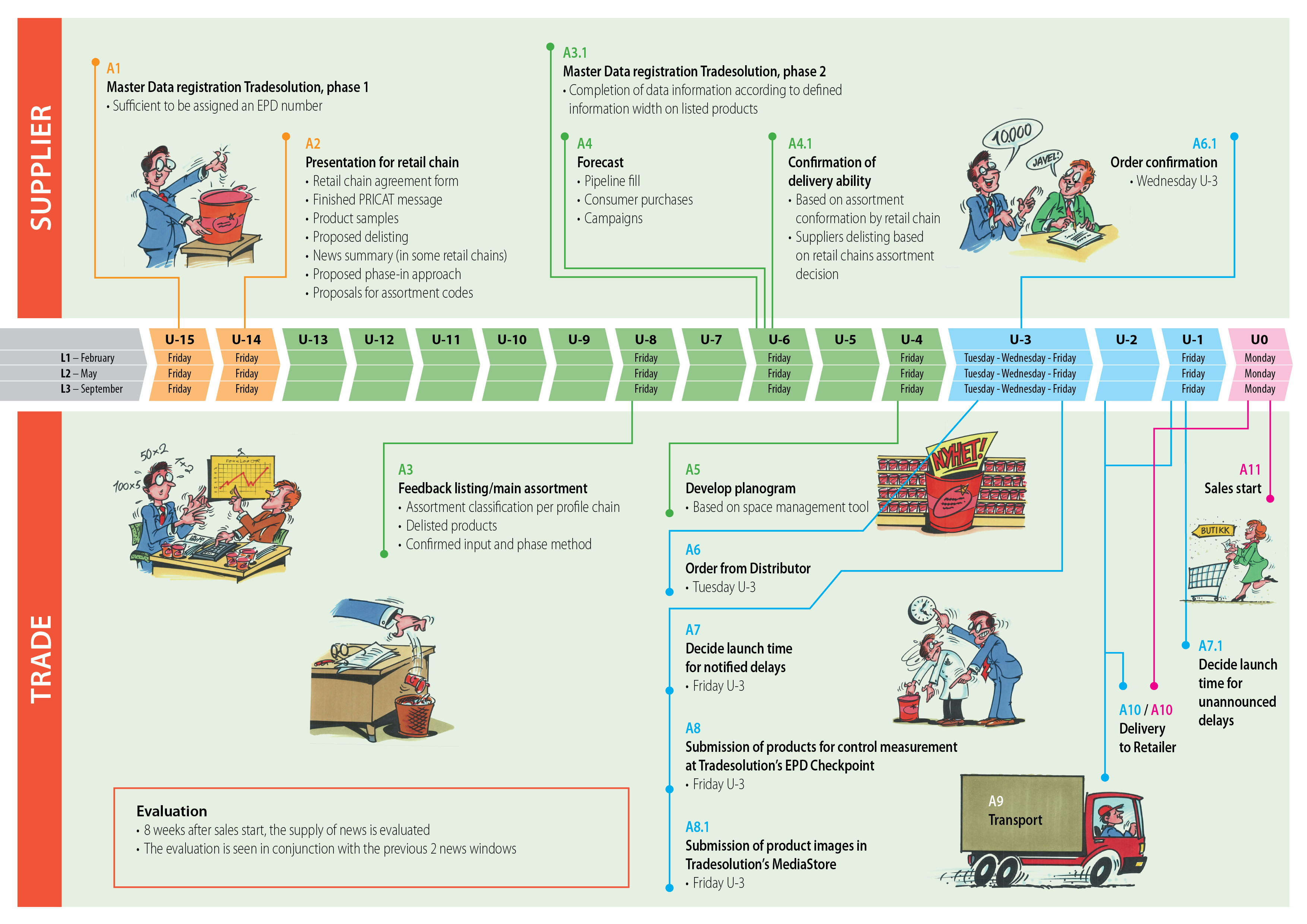

Routine of notified delays (A7 in timeline)

Current deadlines are available in section for downloads.

193 Feedback on listing / main assortment and confirmed ability of delivery (A3-A6 in timeline)

Feedback on listing / main assortment and confirmed ability of delivery (A3-A6 in timeline)

The feedback from the retail chain should include:

- Assortment classification per profile chain (new and old classification)

- Selected input and phase method (time-managed or inventory-managed)

- Included the list of products that are linked

- Products that are delisted

- The time of feedback about assortment is no later than U-8.

If the retail chain’s assortment selection of products leads to a supplier deciding to cancel or postpone launch, this should be reported to the relevant retail chain’s category manager by latest Friday at U-6.

For products being discontinued, any deviations from ordinary down sale must be clearly communicated in a reasonable time.

In case of product shortages at the supplier, the volume as confirmed in U-6 (A4 in timeline) is used as the basis of deviation handling ref.

Routine for delay from supplier / Private label

However, order confirmation of orders (A6) delivered no later than Tuesday in U-3 is to be considered as a binding agreement. Order confirmations will be given Wednesday U-3 (A6.1). Current deadlines are available in section for downloads.

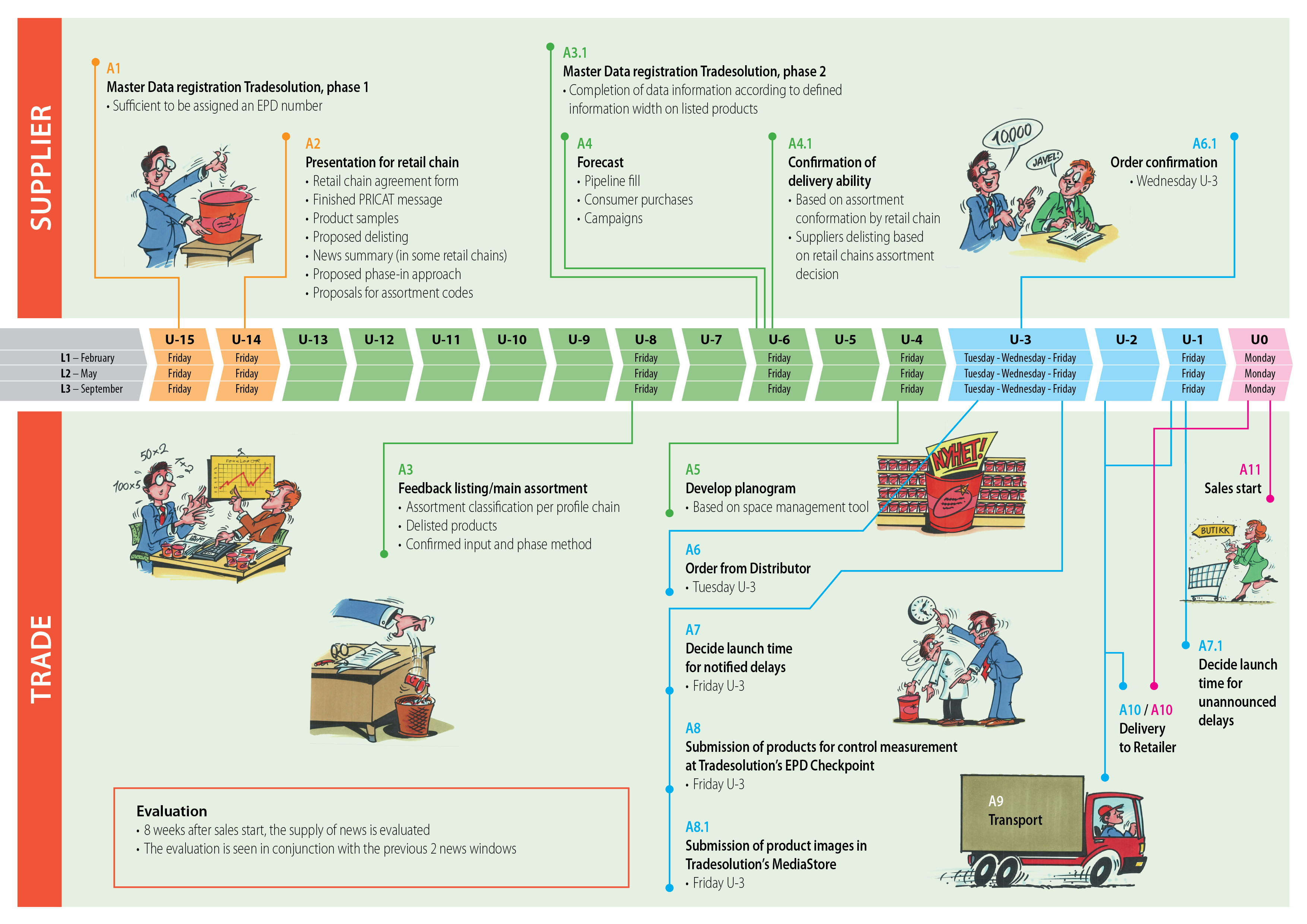

192 Master data registration and product presentation follows a timeline

Master data registration and product presentation follows a timeline

Products distributed over distributor, via Crossdock or directly to retailers following the same path.

The timeline indicates the very last deadline for completion of the respective activity.

Many of the activities are sequential, where startup assumes that previous activities have been completed.

Where possible, encourage mutual involvement as early as possible in the process to reduce costs and uncertainties. See also Communication and data exchange

The retail chains will operate with different forms, but they largely contain the same.

Current deadlines are available in section for downloads.

155 Definitions – Priority target measures

Definitions – Priority target measures

The target measures are based on three important dimensions in the term «service level»:

- Quantity – availability

- Time – reliability

- Administration – security

The priority targets measures should be followed and evaluated continuously with focus on level, trends and development.

Target measures Correct quantity – availability

The target measure “Correct quantity” measures availability as precision in quantity delivered.

Definition:

| Number of delivered sales Units | = Availability |

| Quantity of ordered sales Units |

The quantity ordered is the amount that the customer initially ordered.

Not delivered quantity represents deviations in delivery.

Target measure At the right time – reliability

The target measure “At the right time” measure reliability as precision in delivery time.

The target measure is used to measure compliance with time limits defined in the agreement between the parties.

The target measure can be used along several dimensions in the value chain.

Examples may be if orders are sent at the right time, if order confirmations are sent at the right time, if delivery is picked up at the right time, if Despatch Advice is sent at the right time, etc.

Definition (with example order):

| Number of late or early delivery orders | = Reliability |

| Total quantity of orders |

Delayed or premature is determined by whether exchange / delivery is within the agreed time frame.

At Incoterms Ex Works delivery terms, the assessment of the supplier’s reliability is on the supplier’s ramp.

The delivery is received when the order / delivery etc., is acknowledged for.

Target measures Correct Administration – Security

The target measure “Proper Administration” measures security as compliance between what is ordered in the order and what has been delivered and has been invoiced, that is, the correct product without errors and with the correct documentation.

Definition:

| Quantity of orders without credit / debit notes | = SAFETY |

| Total quantity of orders |

Correct administration means that Despatch Advice, shipping notes, invoices etc. are complete and error-free in relation to the delivery.

Only credit and debit notes affecting physical delivery are included in the measurement.

The target measure can also be used to measure the quality of orders from the customer.

Examples of calculation of service level for priority target measures can be found in the document

Examples of priority target measures

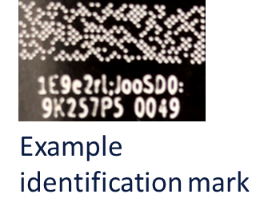

320 Guideline for labelling 2D barcodes on Consumer Units

Guideline for labelling 2D barcodes on Consumer Units

Background

The need for information both in trade and to the consumer is constantly increasing. Today’s solution using the EAN-13 barcode does not provide opportunities for additional machine-readable information. The need for more information has led to products that have more than one bar code applied to Consumer Units, which creates challenges both at the checkout point (POS) and in the value chain. Often this is a QR code with a link to a website where the consumer can find more information.

In parallel with the need for more communication with consumers, a need is emerging at the retail level to gain more control over the traceability and expiry date of the products, to ensure safe food and reduce food waste. This is happening in most countries in the world. In Norway, GS1 Norway, together with Matvett, established a working group consisting of representatives from brand suppliers, grocery chains, system suppliers and other stakeholders to discuss these issues. These guidelines are a result of this work and have now been included as part of STAND’s framework for the Norwegian grocery industry.

Purpose of the use of 2D barcodes in Norwegian grocery

Although 2D barcodes are not the only solution to the challenges, this is the data carrier of the future, where the need for information is greater than just identifying a product with GTIN. 2D barcodes take up less space, can contain more information about the product, are a tool for reducing food waste and increase food security, are more flexible, and can be read by mobile phones. This provides an opportunity for increased consumer contact. In addition, 2D barcodes can solve all needs for information exchange throughout the supply chain, including being able to link to websites.

Different types of 2D barcodes

There are many different 2D barcodes, but only some of them can be used in connection with the GS1 standards, which are the standards used by the Norwegian grocery industry. The different 2D barcodes are also used for different purposes. This is regulated in GS1’s regulations, General Specifications. The difference between the different 2D barcodes helps to determine what they can be used for.

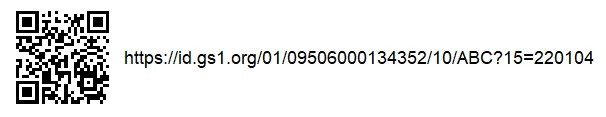

QR Code

The QR Code barcode is in the GS1 system defined to be used only with GS1 Digital Link URI syntax. In practice, this means that this should only be used for communication with the consumer via a URL that links to a website with more information that the consumer can read with his mobile phone. QR Code has grown to become the preferred barcode for consumer communication and most mobile phones today are able to read this with the built-in camera app in the phone. This means that the threshold for reading QR Code is low among consumers, and it is less need for training and communication to put functionality related to QR Code into production. Here you can find more information about QR codes.

GS1 Datamatrix

GS1 Datamatrix is a variant of Datamatrix that uses GS1 Element String syntax. This is the use of AI (Application Identifier) structure. This is a way of structuring the information in the barcode so that everyone who reads the barcode understands the content in the same way regardless of the order in which the information is printed and how much information is in the barcode. According to GS1 General Specifications, GS1 Datamatrix is only permitted for use on Consumer units with variable measure and prescription medicines. However, it is permitted to use it in limited pilots, for test purposes and in closed value chains under controlled conditions. The advantage of GS1 Datamatrix is that it has high compression and error correction. It can be printed both square and rectangular so that it can fit where there is not enough height, but enough width to get the information needed without compromising on size and thus readability. However, the rectangular version has a limit on the amount of data that can be used. GS1 Datamatrix is the only permitted barcode on prescription drugs. Here you can find more information about GS1 Datamatrix.

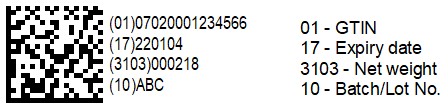

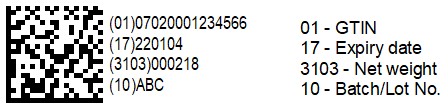

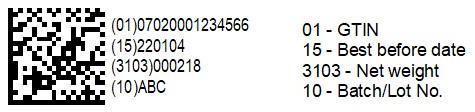

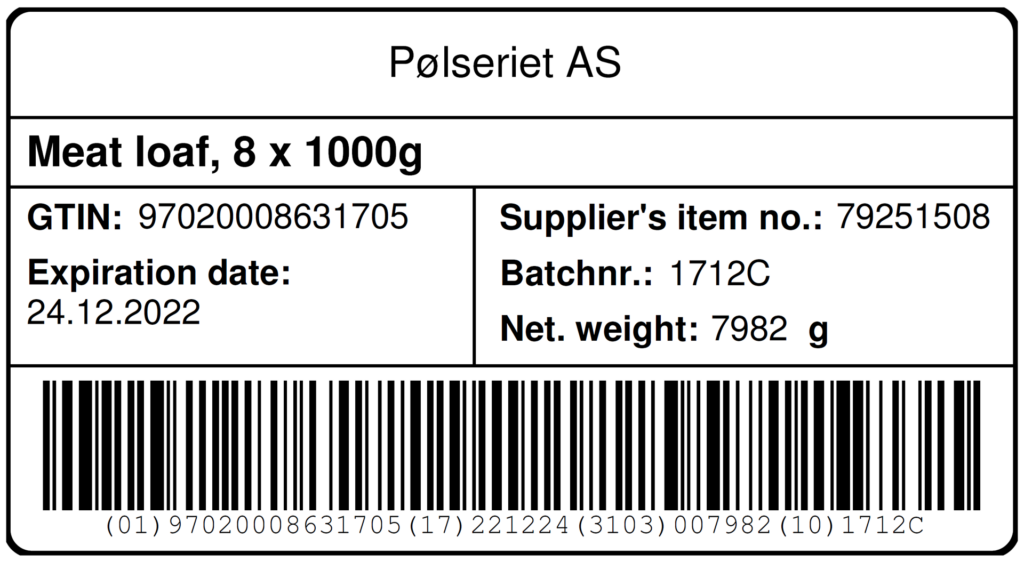

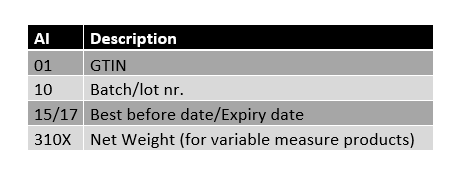

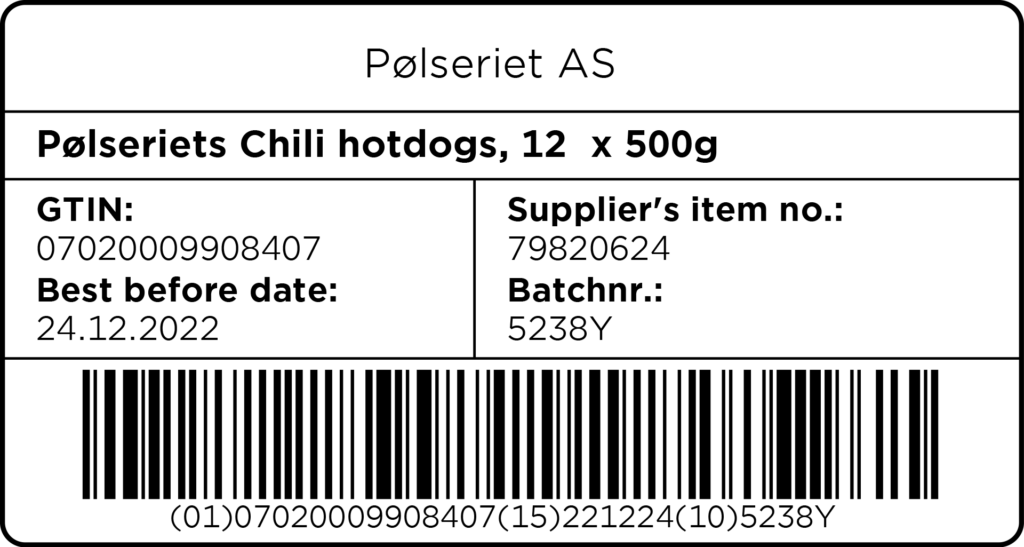

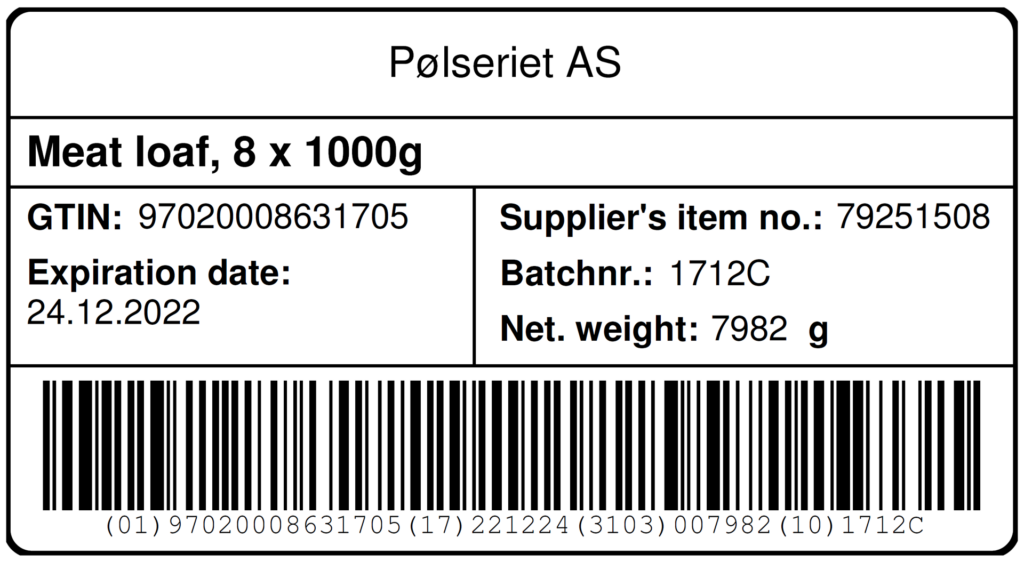

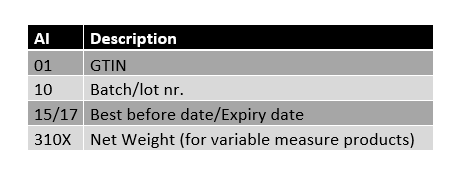

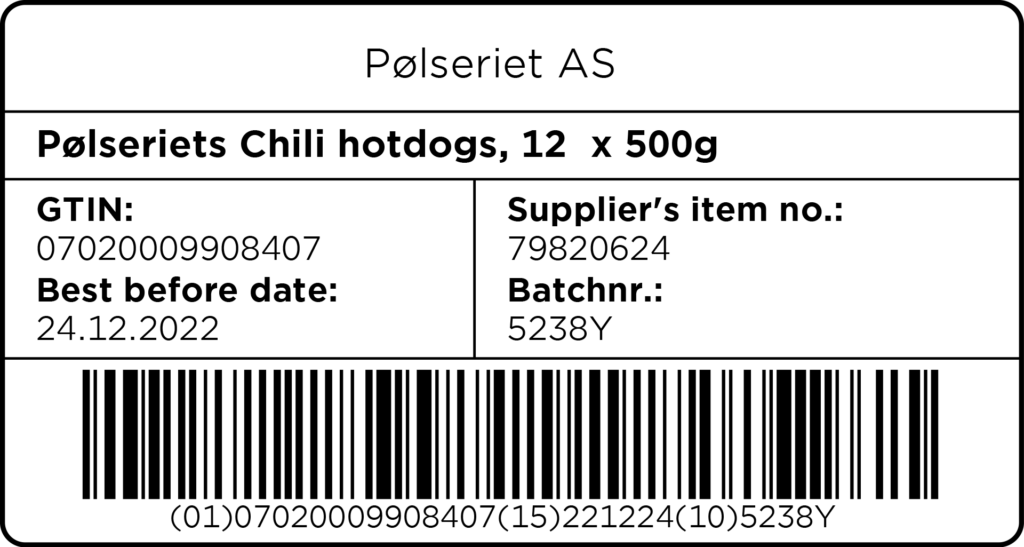

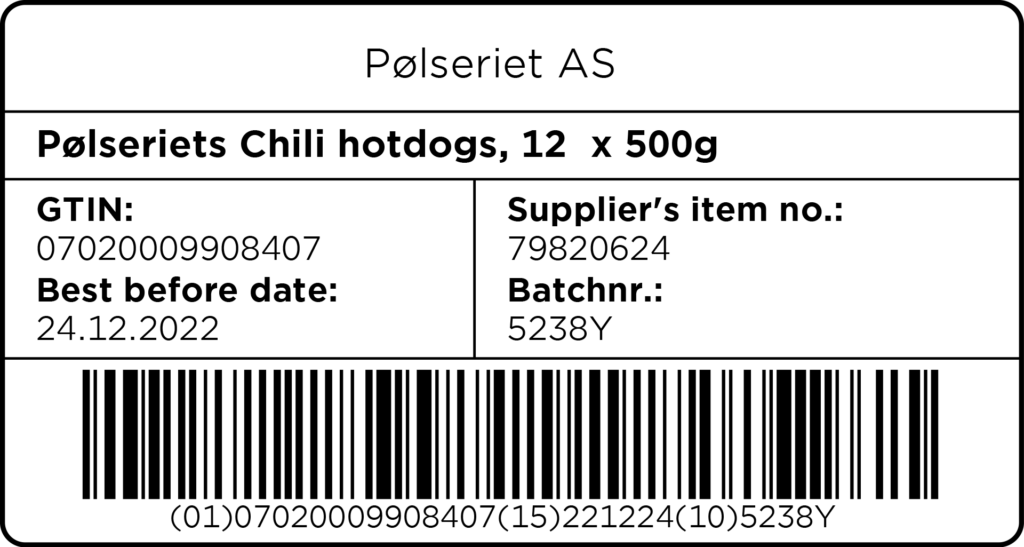

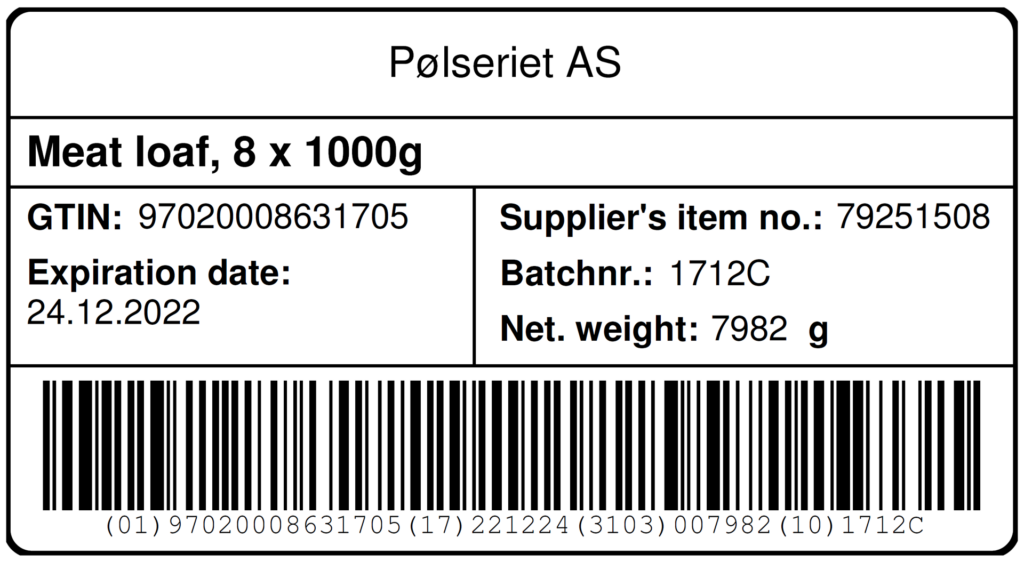

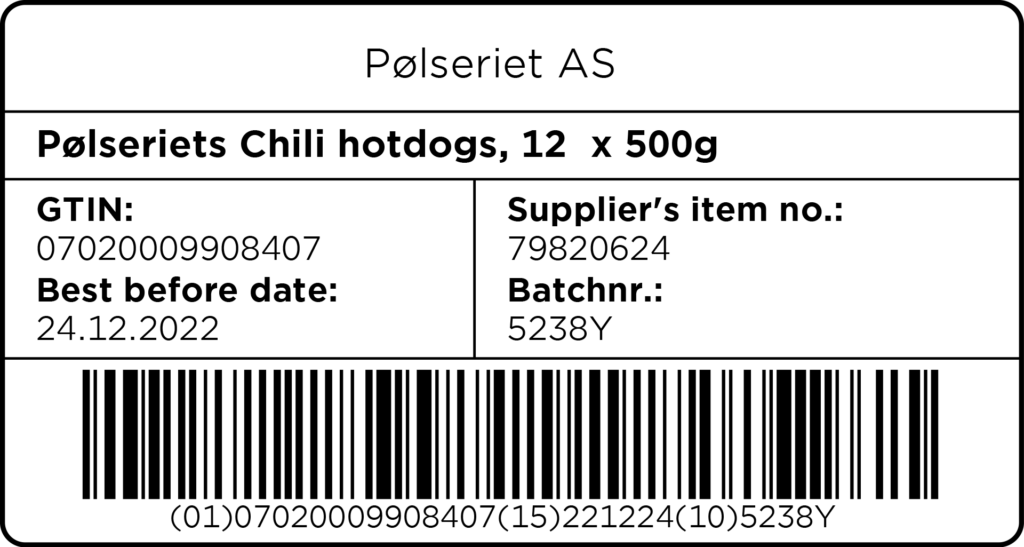

Content in barcode

A minimum requirement for information attributes has been defined for POS purposes.

This is:

- GTIN

- Best before date or Expiry date

- Batch/lot nr.

- Weight (for variable measure products).

It is possible to use other Application Identifiers for internal and/or external needs, but this is then up to each individual actor to use.

319 Actions to be made in case of an incident or crisis

Actions to be made in case of an incident or crisis

Alarm / Notification

An incident can occur in all steps of the value chain, at the consumer, retailer, distributor or at the supplier itself. It is important that the supplier is notified as soon as possible.

Notification of an incident shall be given to one alert point at each operator. The alert point should be agreed in advance and always be staffed / available.

The industry has decided that for products registered in the Tradesolution EPD base, Tradesolution ReCall portal should be used for blocking, recall or withdrawal. Access is available at epd@tradesolution.no

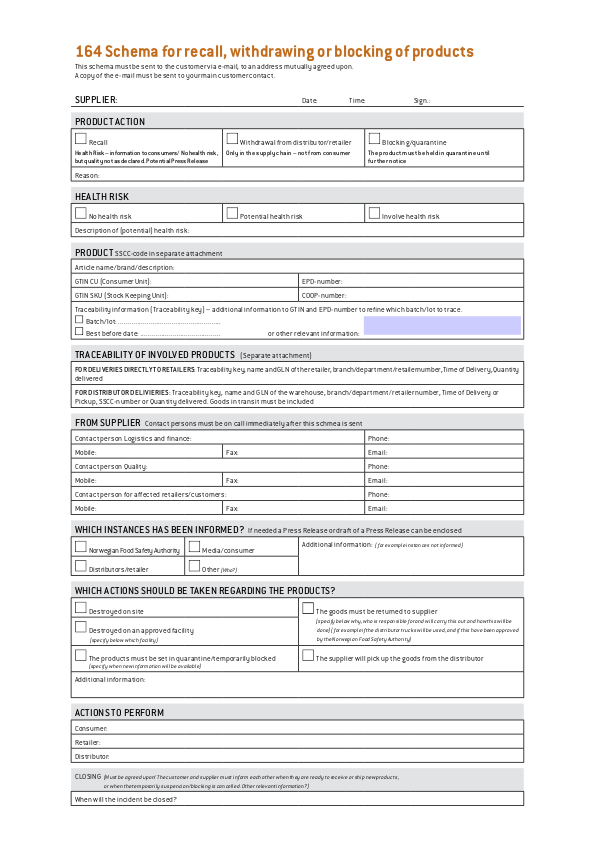

For products not registered in the Tradesolution EPD base, a Notification schema for recall, withdrawal or blocking of a product may be used provided that this has been agreed between the supplier and the distributor/wholesaler. Notification schema can be downloaded from Downloads.

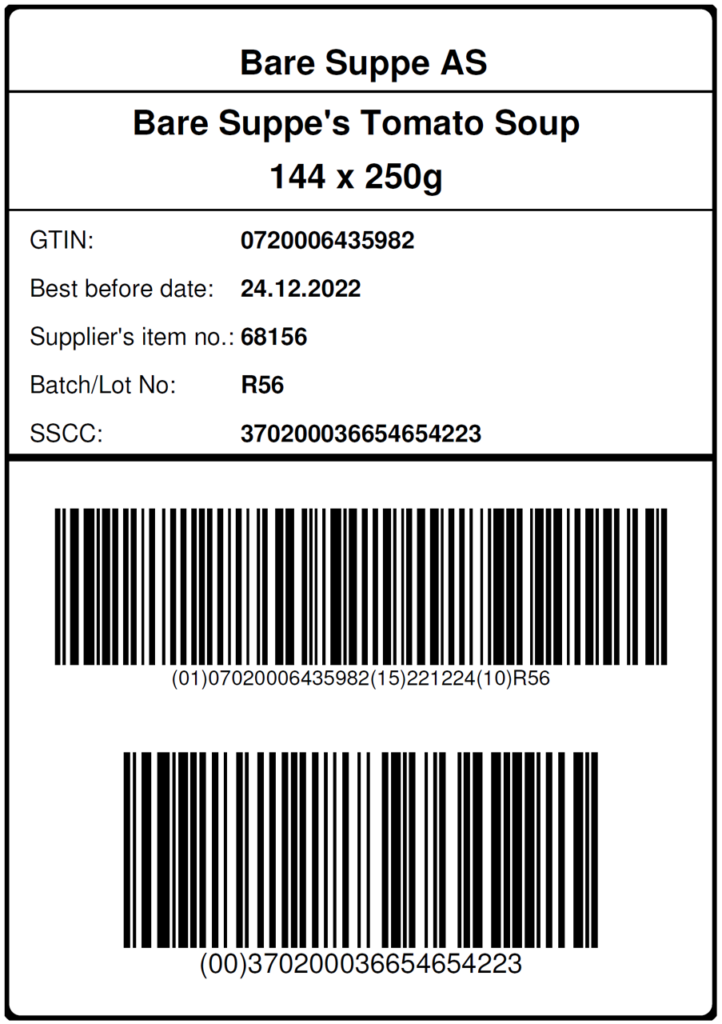

Required information to follow an alarm / alert

To identify the scope of the alarm / alert, the product’s GTIN / EPD, best before date, batch / Lot number and SSCC on affected pallets must always be stated. This applies regardless of whether the product is registered in the Tradesolution EPD base or not.

By using the portal, the supplier gets / is secured

- Easier, faster and more efficient registration, as well as quality assurance of the necessary product information

- Ensure that necessary information is distributed quickly and efficiently to all relevant recipients

- Simplifying the dialogue between the parties

- All dialogue and information exchange is done in the portal and can be logged and stored.

The ReCall portal can also be used in situations where you want to withdraw products with quality defects.

Distributors have built their own systems and routines for alerting crisis situations and blocking the products at their distribution warehouses and retailers. This is not part of the ReCall portal.

The following routine applies when registering an incident or crisis

- Register a new case

- Determine severity and health hazards

- Notify affected parties / recipients

- Register distribution and what to do with the product

- Register tracking information for affected batches / lots

- Describe further actions to be taken, with press releases and other additional information

- Closing the case

The practical implementation of the routine is described here Routine when registering an incident or crisis, in the Tradesolution ReCall portal.

Conclusion

Through the guidelines, the industry contributes to satisfying consumers’ demands and expectations for safe products, provided that an overall industry complies with the guidelines.

Should an incident or crisis occur, there are routines and tools that, in a simple, fast and secure way, limit incidental damage.

An accurate and limited recall or withdrawal will be possible.

This reduces costs for all parties in the value chain and minimizes potential reputational loss.

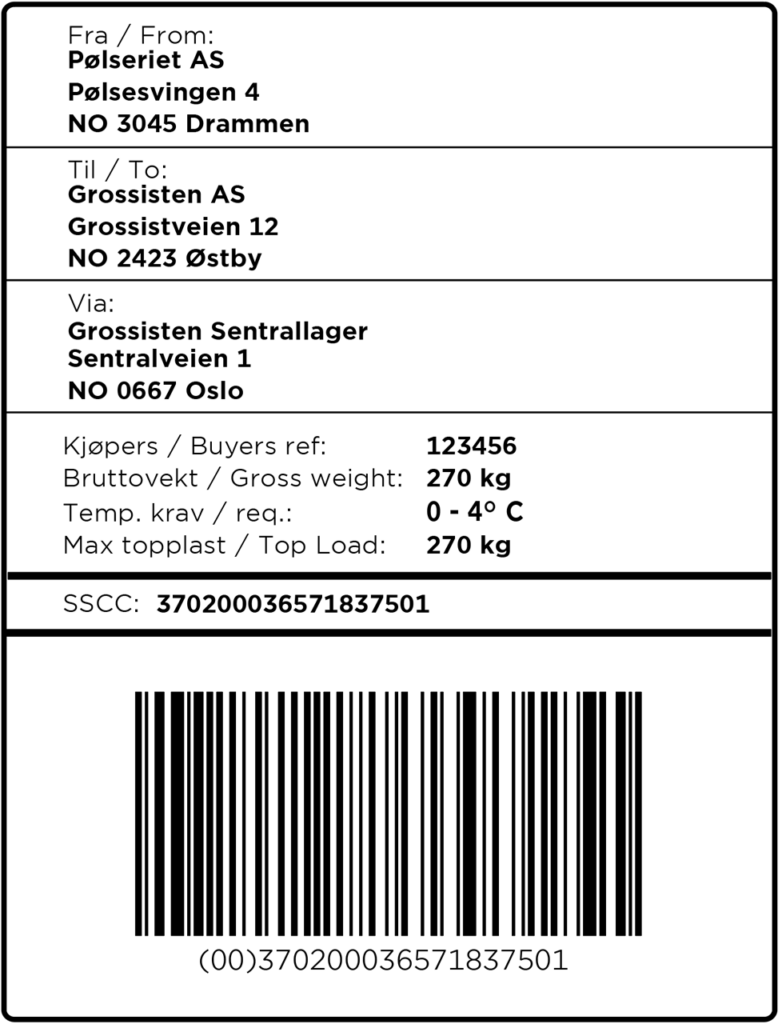

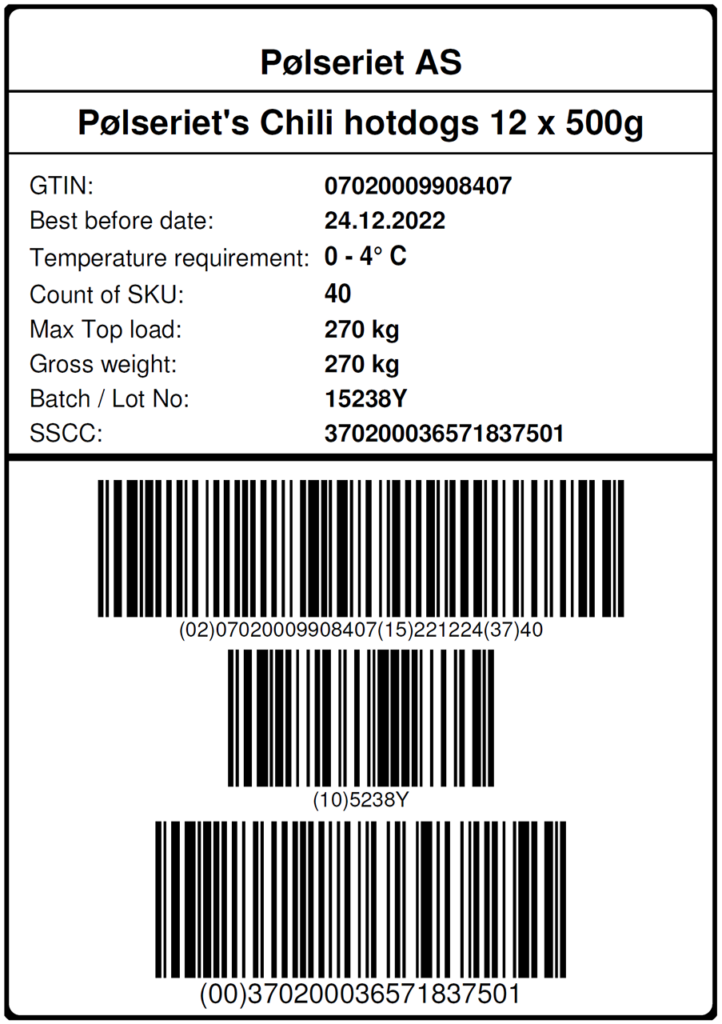

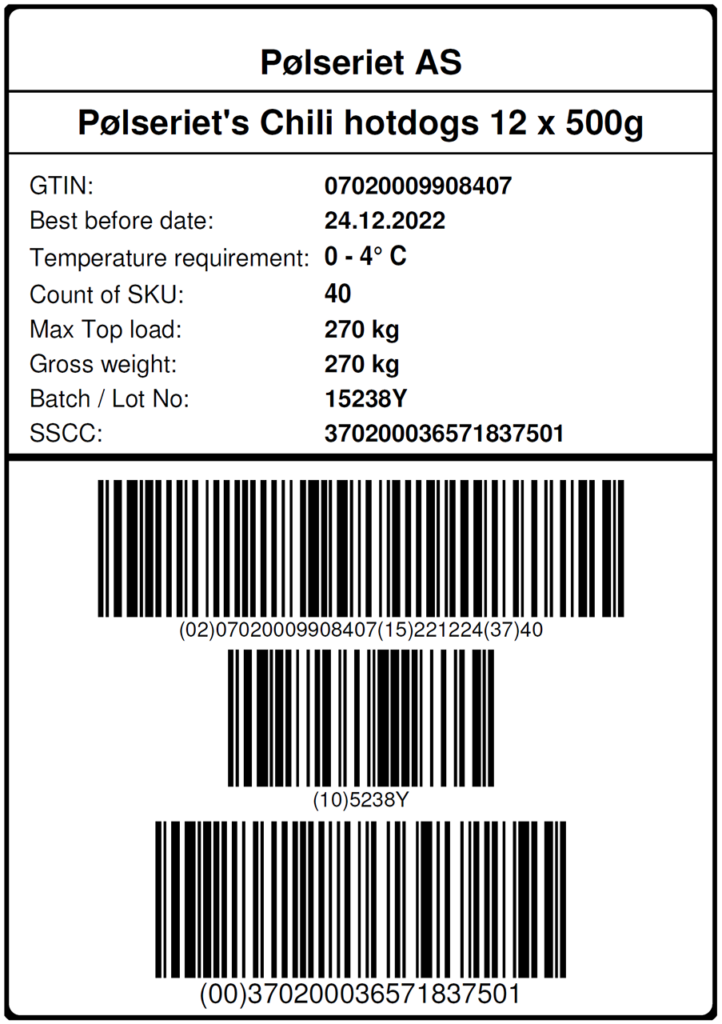

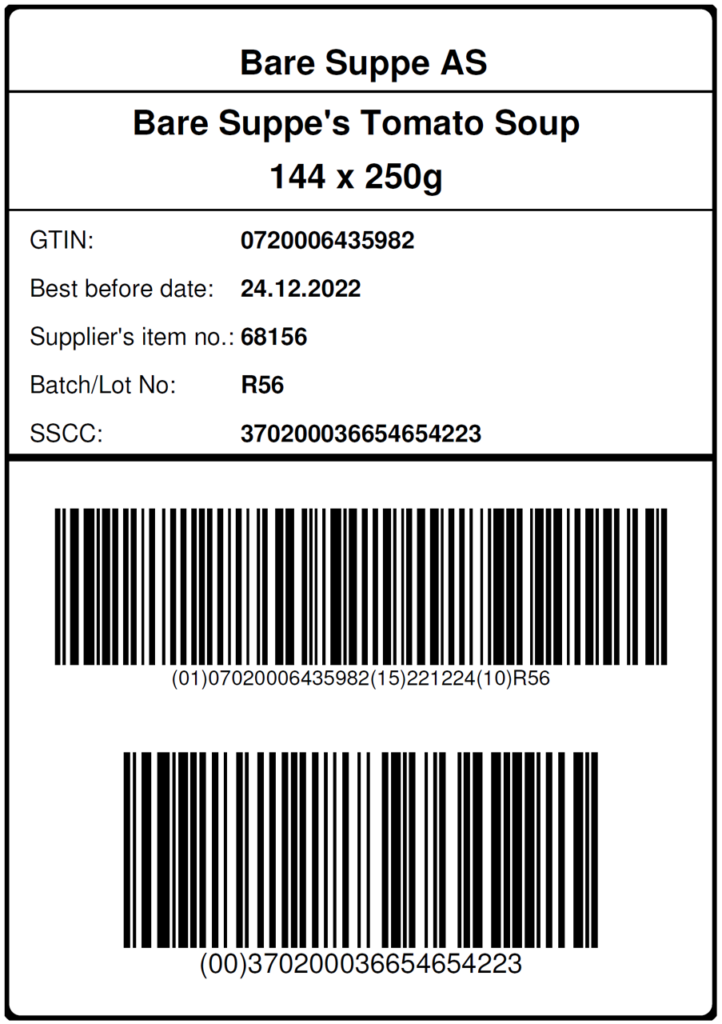

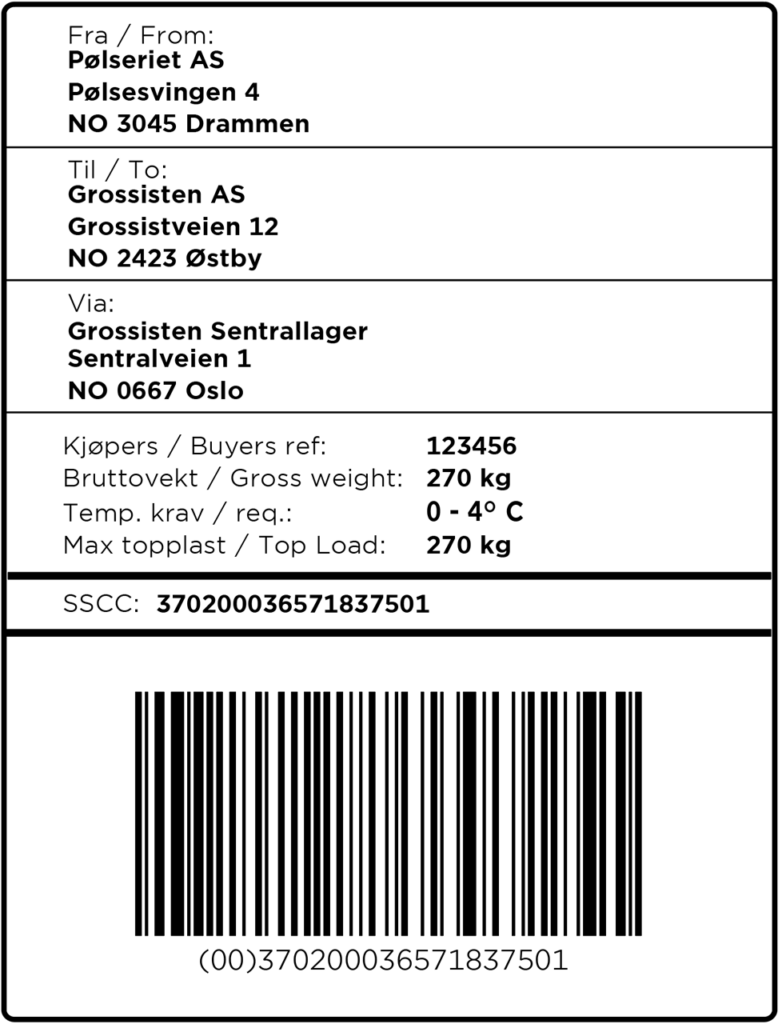

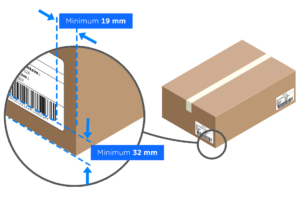

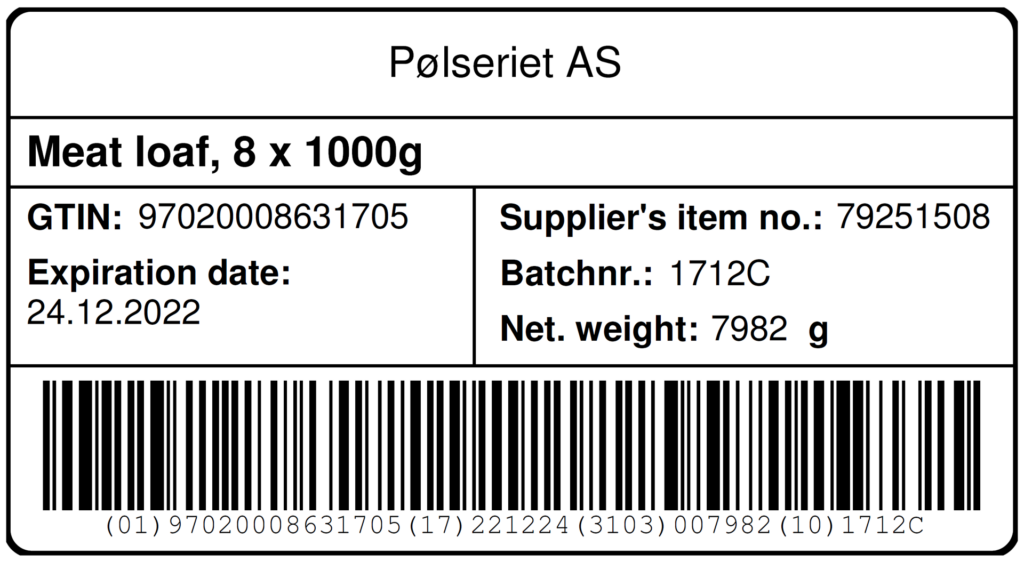

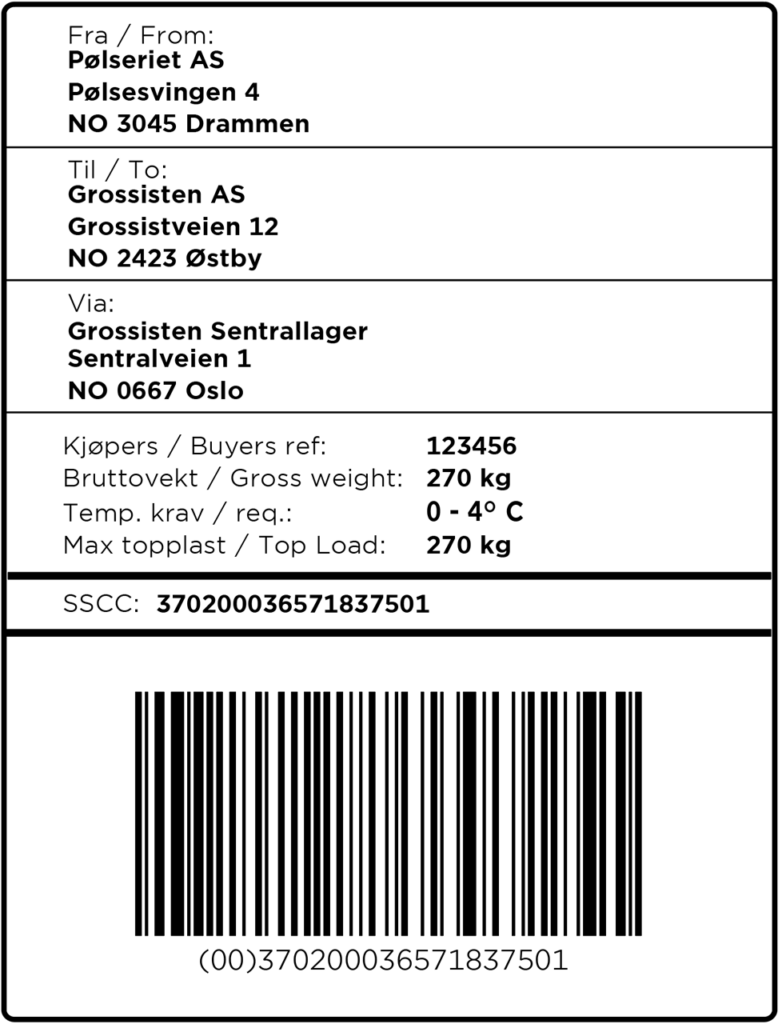

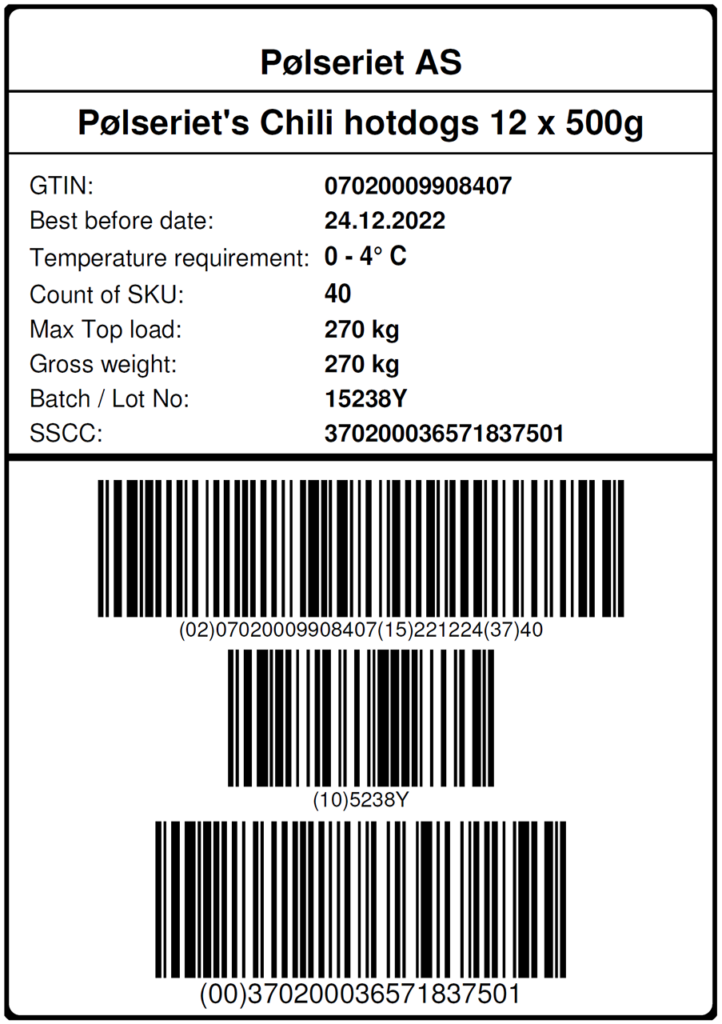

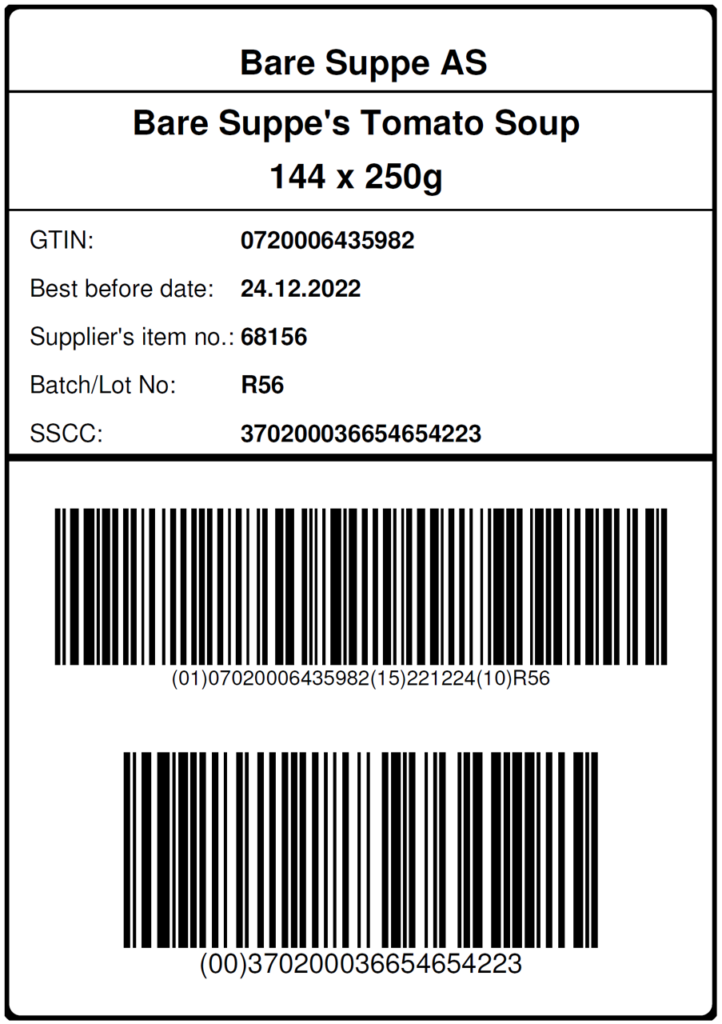

316 Requirements for tracking information and labeling

Requirements for tracking information and labeling

The main purpose of the tracking information is to lay the groundwork for effective blocking, withdrawal or recall of products.

Central tracking information is:

- GTIN (Global Trade Item Number) – Unique identification of products

- GLN (Global Location Number) – Unique identification of trading parties, pick-up points, delivery points etc.

- SSCC (Serial Shipping Container Code) – Unique identification of load carriers / pallets

- Batch / lot number – A unique batch or lot number defined by supplier / manufacturer

- Shelf life – Either Best Before date or Last Consumption Date

It is a requirement that the products are labeled to enable tracking.

The marking must be affixed to the product packaging and legible.

The following applies to finished goods traded between supplier and distributor / retailer:

Information to be marked:

- The name of the supplier

- Product name/description

- Product number identified with a GTIN.

- Best before date / last day of consumption date, if required

- Batch / Lot number, if required

Load carrier (for example pallet) shall be marked with SSCC.

The sender must in his system have an overview of which recipient the product was sent to, and also the recipient must have an overview of which sender the product was received from. Both sender and recipient must be identified with GLN.

Sender shall in his system register:

- Quantity sent

- Shipping Date

- Reception date (if known)

Recipient shall in his system register:

- Quantity received

- Shipping date (if known)

- Reception Date

The following applies to raw materials and other inputs:

- GTIN should be used for identification of inputs / raw material, if available

- GLN should be used for identification of sender / suppliers, if available

More about tracking information and how the product can be tracked in the value chain is described here Recommended traceability methods in the value chain.

318 Prepare a Contingency Plan

Prepare a Contingency Plan

If unwanted incidents or crises occur, it is important to be well prepared.

Possible scenarios for what might arise should be thought through and how this should be handled.

A Contingency Plan must be prepared that will allow you to cope with the situation quickly, correctly and effectively. The Contingency Plan must be accurate and accessible to all involved at all times.

The Contingency Plan includes:

- To designate a crisis team, responsible for traceability, recall and withdrawal.

- Internal and external contact lists to quickly reach everyone involved or affected by any incident or crisis

- Training and exercises in the company’s routines and instructions on how to handle incidents or crises. Exercises should be as realistic as possible and carried out with the closest business partner in the value chain

- This must be easily accessible and may consist of, for example

- a brief overview of crisis teams with their roles and responsibilities

- the company’s internal guidelines for handling incidents / crises

- contact lists

- other relevant documentation that is important to have access to should an incident or crisis occur

See more about the Contingency Plan here Design and contents of a Contingency Plan.

317 Prepare a Risk Analysis

Prepare a Risk Analysis

At the heart of the legislation is the duty of each company to carry out a risk analysis of the health risks the products represent and how the company will relate to this in terms of traceability.

The purpose of the analysis is to reduce / prevent risk through

- Withdrawal of products from the market, or

- Efficient notification or recall of products from consumer

This assumes that the parties are aware of the risks the products may pose and have a preparedness that ensures that they react quickly, correctly and effectively in unwanted incidents. A Risk Analysis should therefore be performed on new products based on an intended relevant incident, so that it can be implemented as quickly as possible should a real incident occur for the product.

The risk analysis consists of three elements that both the government and industry should work on in an equal way:

- Risk Assessment

- Risk Management

- Risk Communication

See more about risk analysis here Design and content of a Risk Analysis.

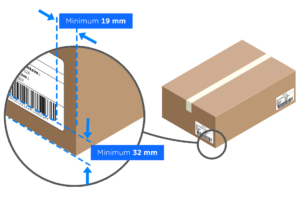

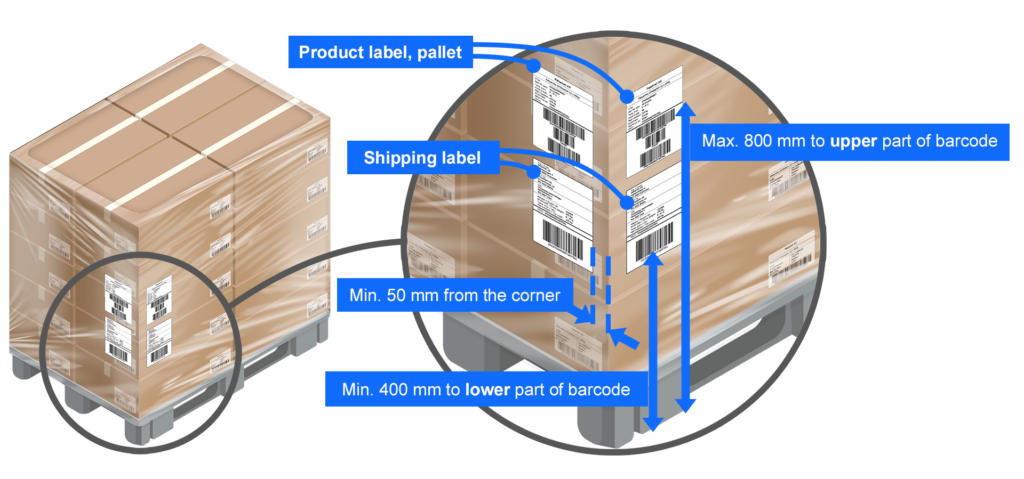

147 Purpose of labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU)

Purpose of labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU)

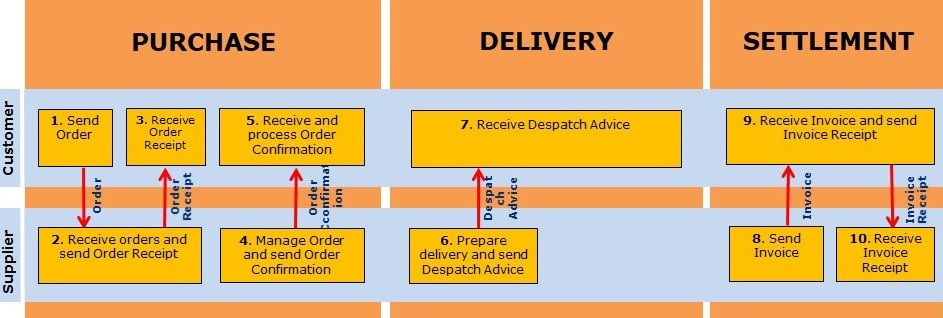

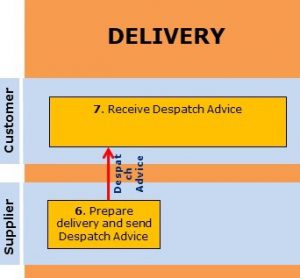

The purpose of a standard for labelling of Stock Keeping Unit (SKU) and Distribution Unit (DU) with subsequent electronic data interchange (EDI) is to:

- Achieve an efficient flow of products from manufacturer to consumer

- Ensure traceability through the value chain, which is important in case an event or crisis occurs which requires a recall or withdrawal of the product

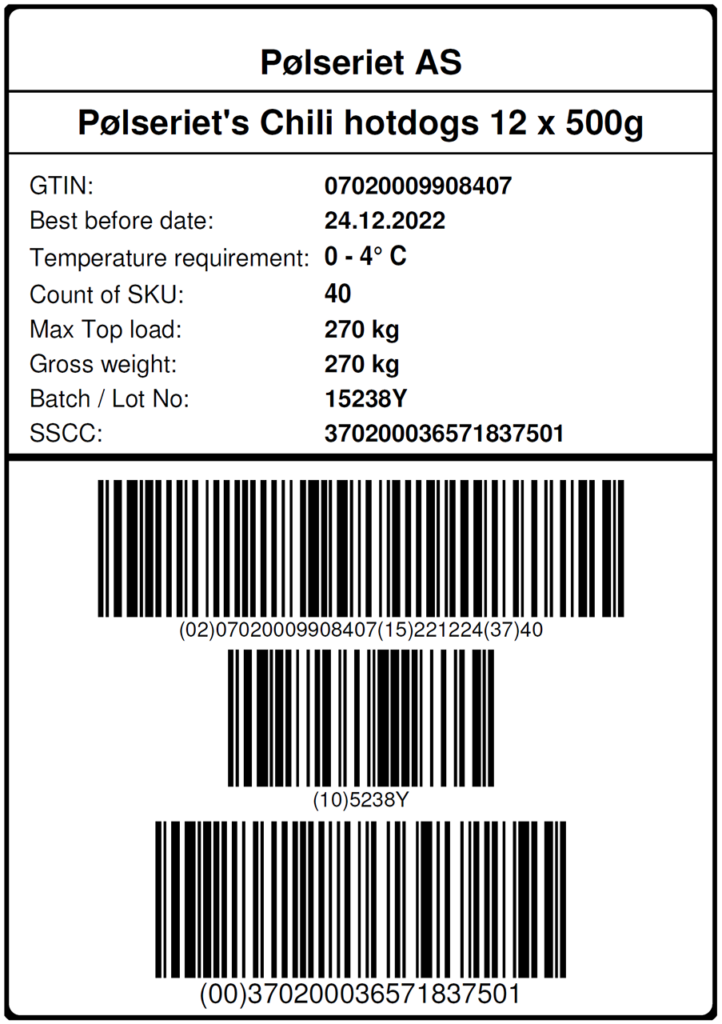

The basis for this is the labelling of each Distribution Unit (DU) with a unique SSCC.

This code is the main key in the electronic Despatch Advice and is linked to information about which GTIN which the Distribution Unit (DU) consists of, the number of Stock Keeping Units (SKU) batch / lot number and shelf life information if applicable.

SSCC is the most important key for traceability of Distributions Units (DU), see Recommended way to track and trace a product in the value chain.

For that reason SSCC shall not be reused until after a minimum of 6 years.

Recommended way to track and trace a product in the value chain

Efficiency and traceability are achieved primarily through:

- Synchronization of product information between the various parts in the value chain.

The purpose is for all players to obtain correct and coherent product information about the products. Between suppliers and retail chains in the Norwegian groceries sector the EPD database is used for the registration, quality assurance and distribution of product information.

- Electronic Data Interchange (EDI) between the actors.

The purpose is to reduce manual operations and reduce lead time in the value chain. The most widely used EDI messages are order, order confirmation, Despatch Advice and invoice.

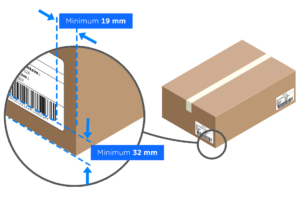

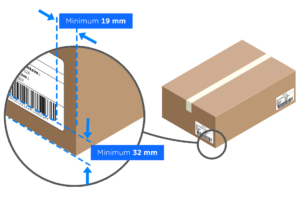

- Standardized labelling of outer packaging.

The purpose is to contribute to faster and more efficient shipping, distribution and receipt of the products. A common labelling concept for the grocery industry is used here; GS1-128.

To ensure rational product and information flow in the distribution chain, STAND recommends a uniform labelling of Stock Keeping Units (SKU) and Distribution Units (DU).

This simplifies the labelling of the manufacturer / supplier, shipment by shipper / freight forwarders and merchandise at distributor / store.

This labelling concept also applies to types of transport units other than pallets.

For fish and fish products, the following applies:

STAND has decided to refer to Norwegian Standard NS17099:2020 “Information technology — Fishery and aquaculture products — Requirements for labelling of distribution units and pallets in the trade of fishery and aquaculture products” for products that fall under this category. This standard replaces todays NS9405: 2014 “Fish and fish products. Requirements for labelling of distribution units and pallets in the trade of fish and fish products», and is valid as from 30. September 2020.

It can be ordered from Standard Norway.

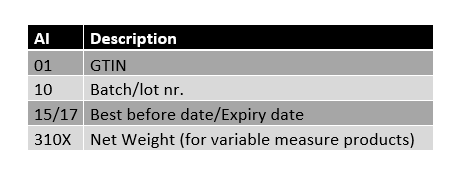

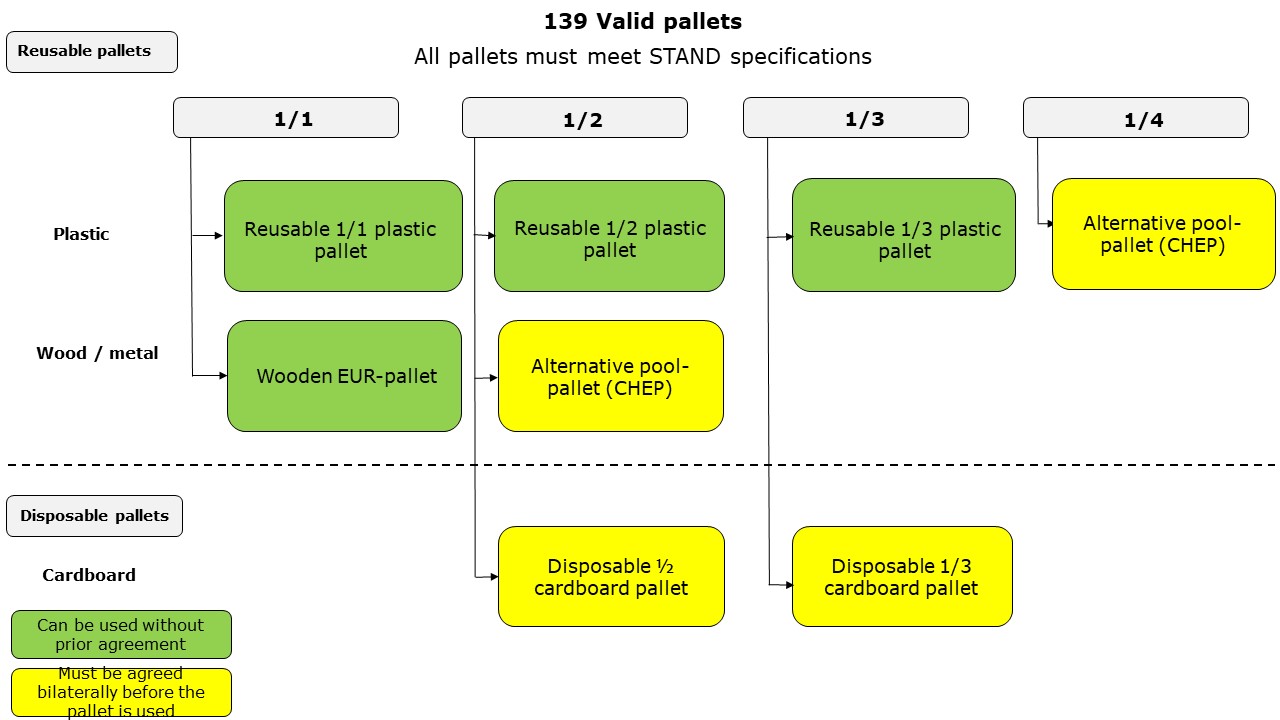

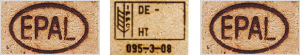

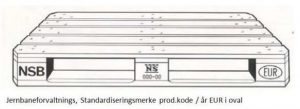

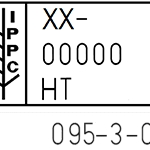

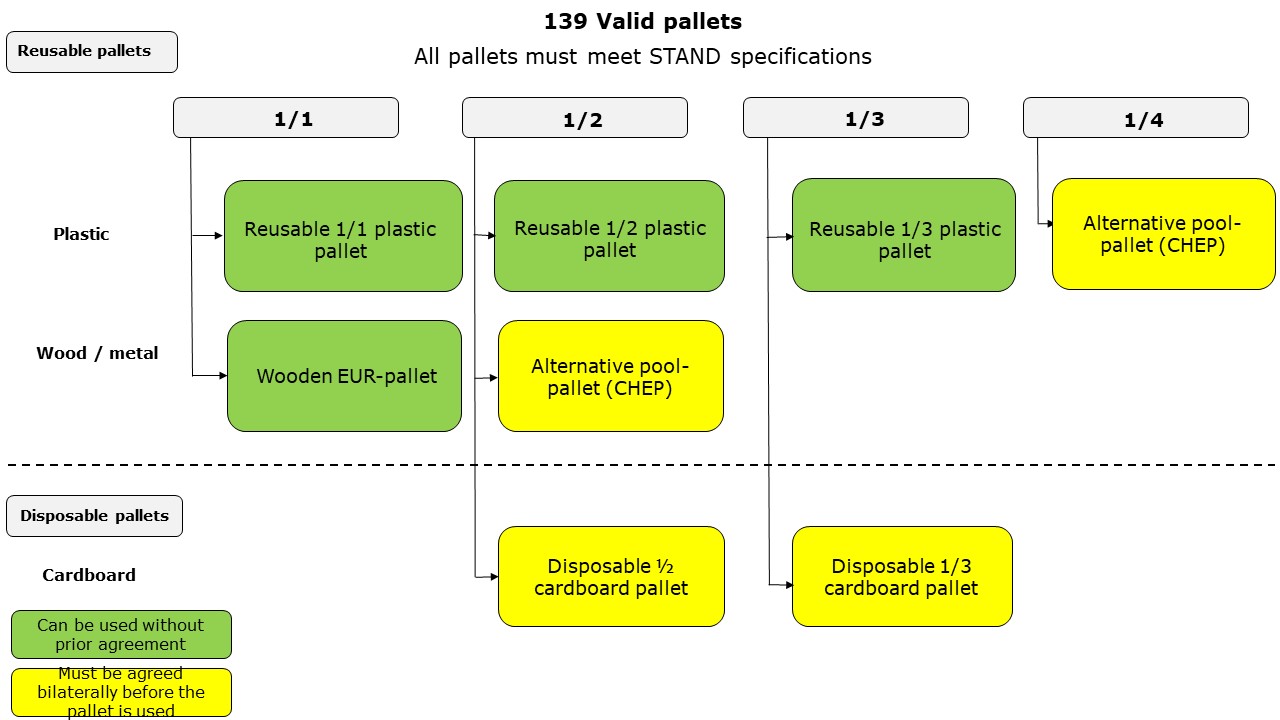

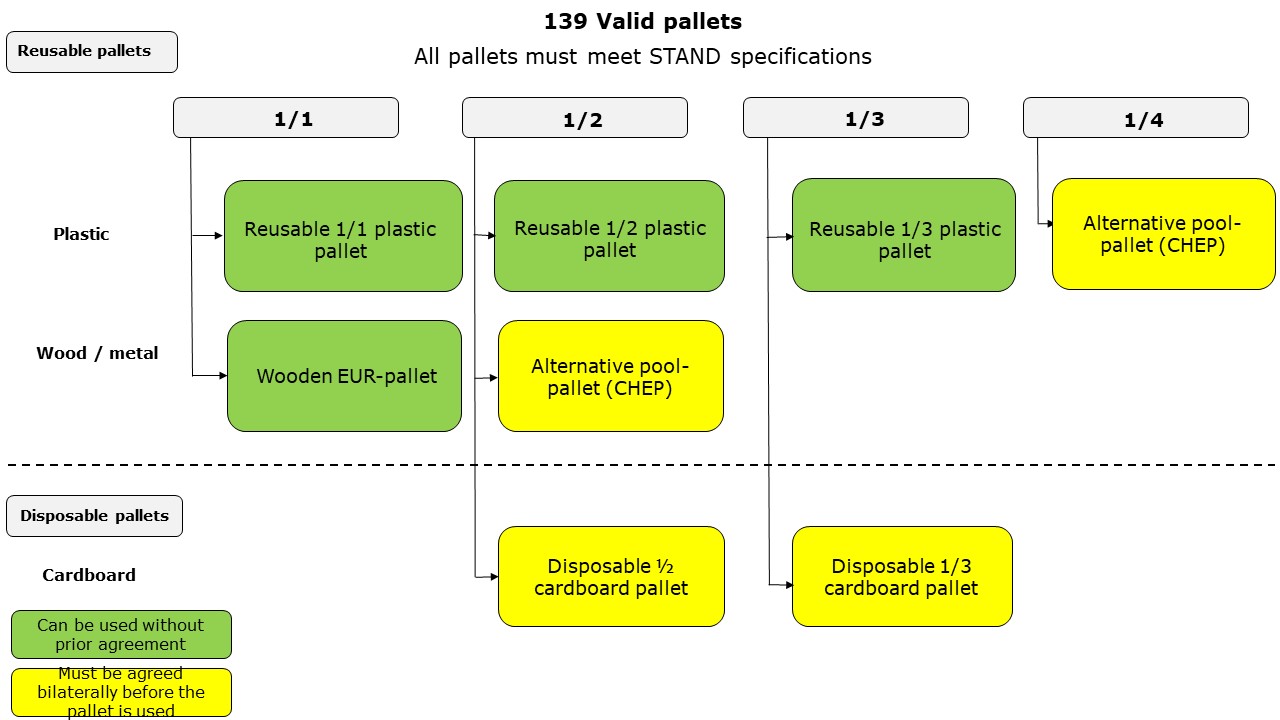

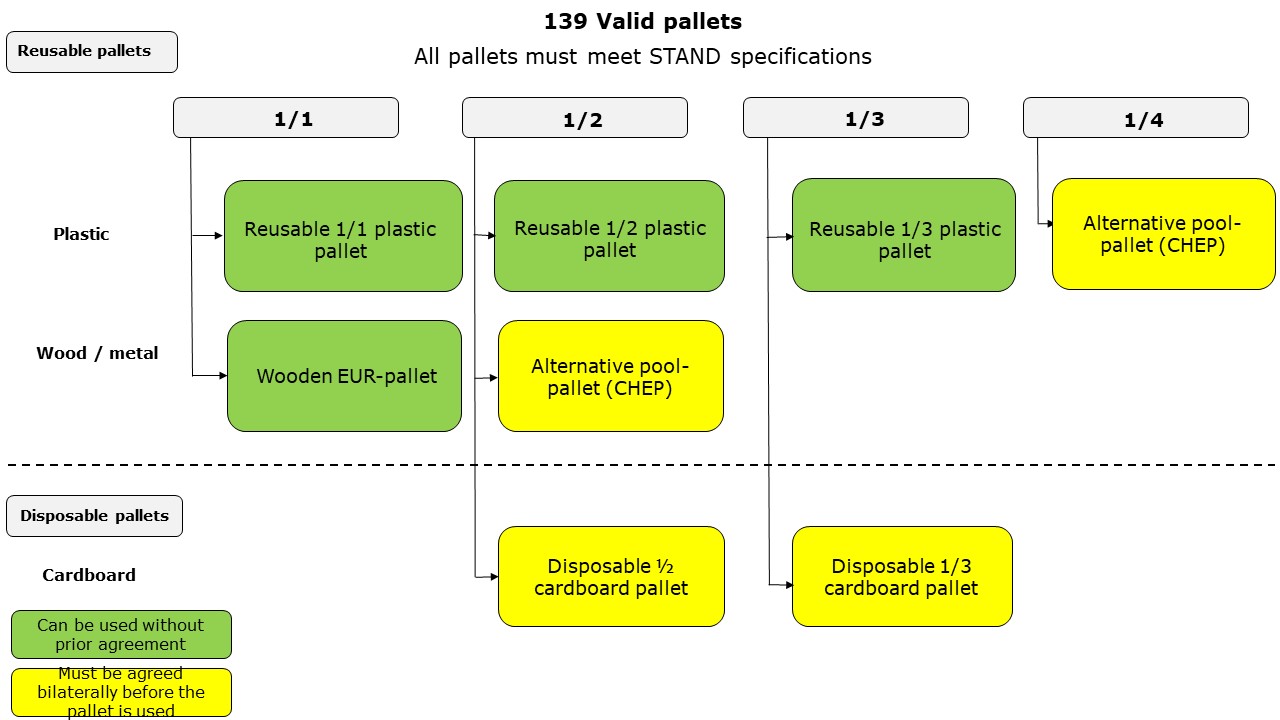

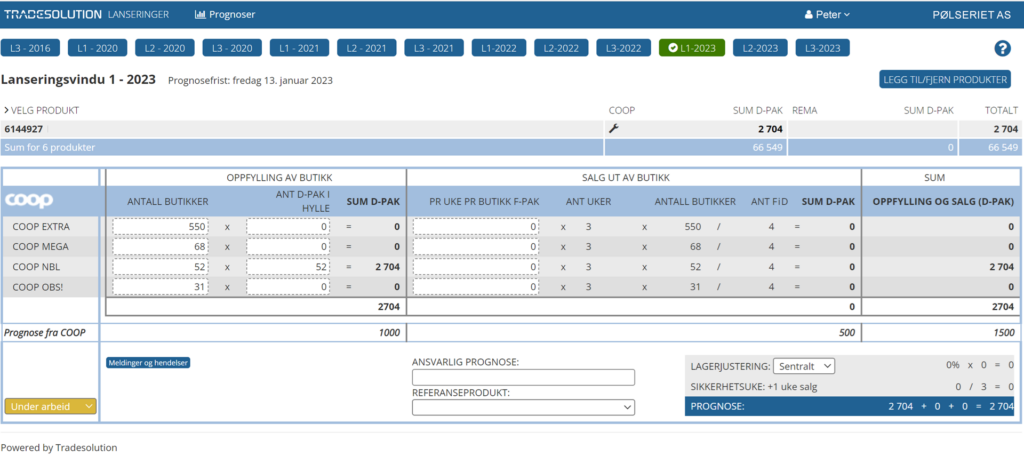

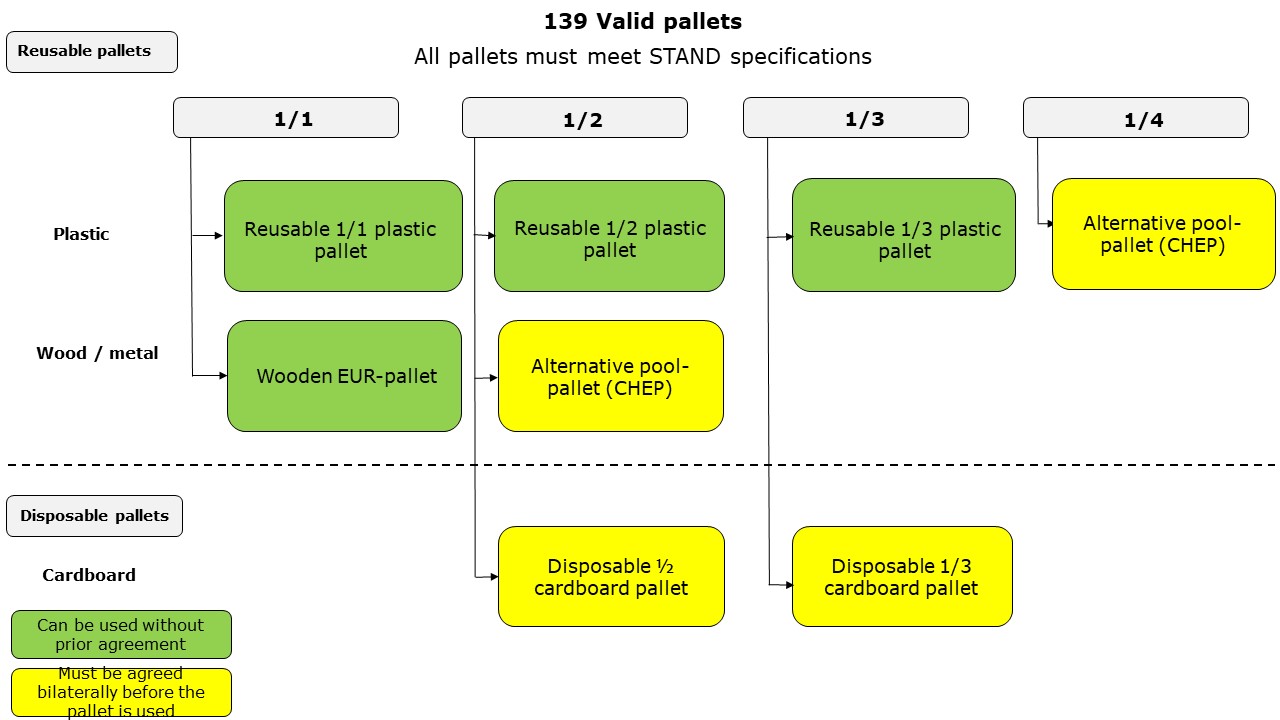

139 Valid pallets

Valid pallets

This is an animation that show what pallets are valid for distribution.

Requirements specifications can be downloaded here:

Requirements for approved EUR-pallets

Specification for reusable 1/1 plastic pallet

Specification for reusable 1/2 plastic pallet

Requirements specification for reusable 1/3 plastic pallet (from NLP)

Specification for reusable 1/4 plastic pallet

Requirements Specification reusable 1/2 wooden pallet

Requirements specification for 1/3 and 1/2 disposable cardboard pallet

174 Placement of Stock Keeping Unit (SKU) on pallet

Placement of Stock Keeping Unit (SKU) on pallet

It is a prerequisite for maintaining strength, that Stock Keeping Units (SKU) are placed within the edges of the pallet with a small margin.

Devices placed on or outside the edge can cause damage with subsequent reduced carrying capacity / risk of injury.

The pallet area should be utilized as best as possible with products. By following the Modular system optimal use of the pallet is ensured and reduces the risk of the load shifting during transport.

Overhang is not accepted.

172 Requirements for design of Stock Keeping Unit (SKU) and packaging

Requirements for design of Stock Keeping Unit (SKU) and packaging

Stock Keeping Unit (SKU) is the unit the retailer buys.

Stock Keeping Unit (SKU) occurs in various forms, such as carton, reusable box / pallet box, intermediate carton and such.

The most important task of the Stock Keeping Unit (SKU) is to secure Consumer Units (CU) from the time of manufacturing until it is finished exposed in a shop shelf.

The number of Consumer Units (CU) in a Stock Keeping Unit (SKU) is determined by the manufacturer, preferably in dialogue with the distributor / retail chain.

The Stock Keeping Unit (SKU) must be adapted to the modular system, see Modular system

for picking and grouping of products can be done as efficient as possible.

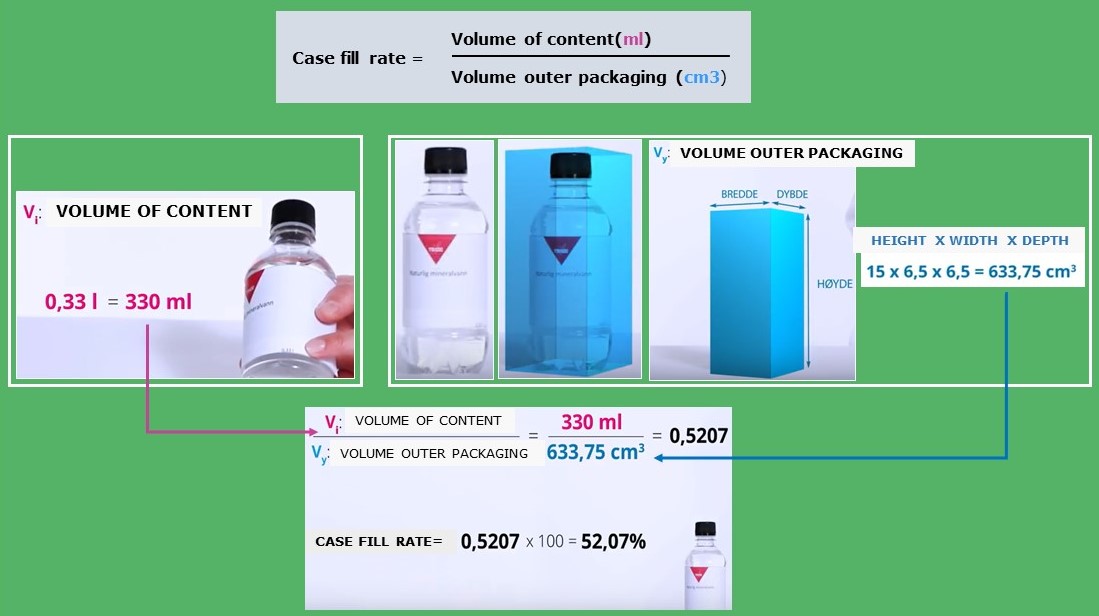

Case fill rate shall be calculated. This is described in Case fill rate

Stock Keeping Unit (SKU) must be designed to withstand the strain required in the value chain.

Automatic warehouses require that Stock Keeping Units (SKU) must be packed in a way that it can be lifted, stacked, clamped and handled with different mechanized devices, see Automated warehouse at distributor – greater understanding of the depalletization process.

Design requirements and packaging

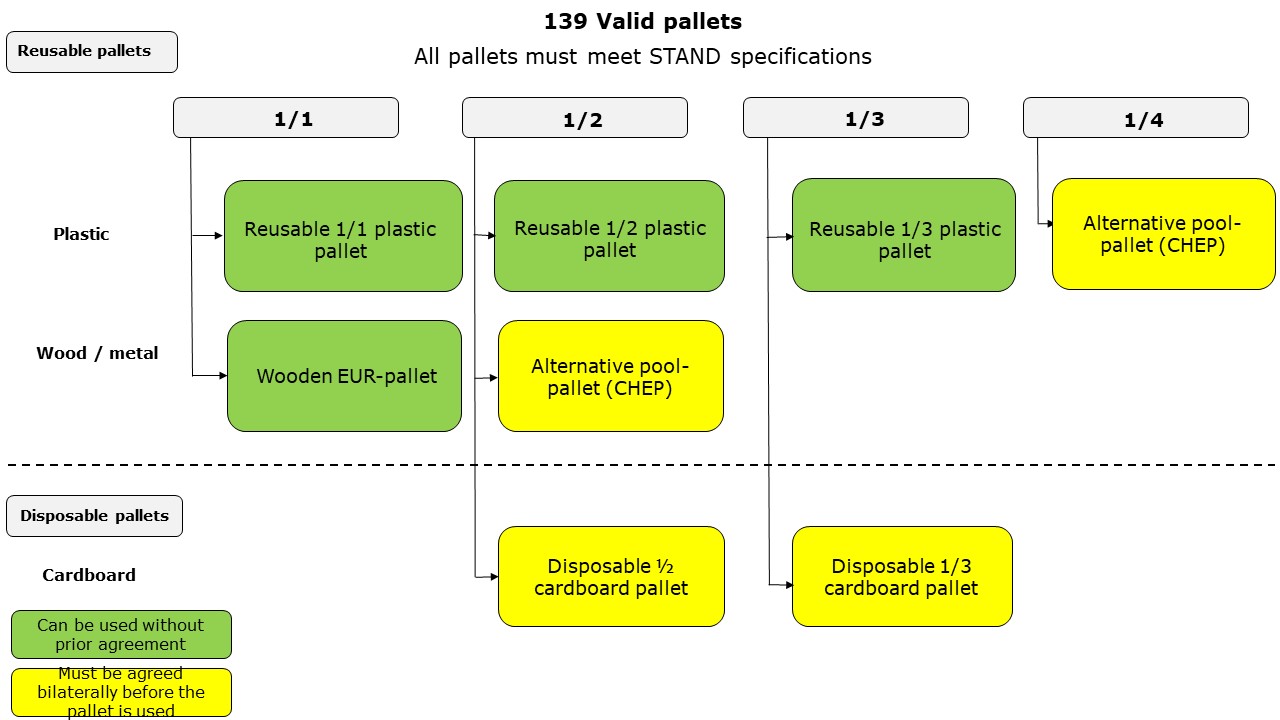

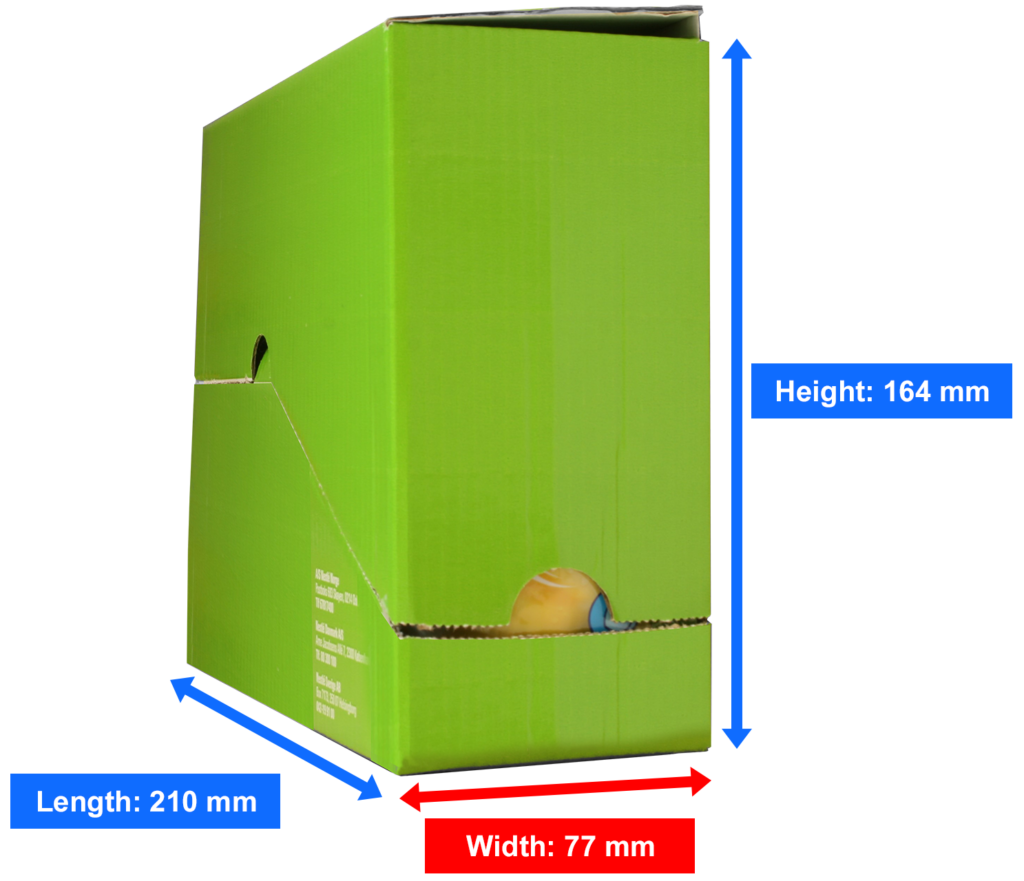

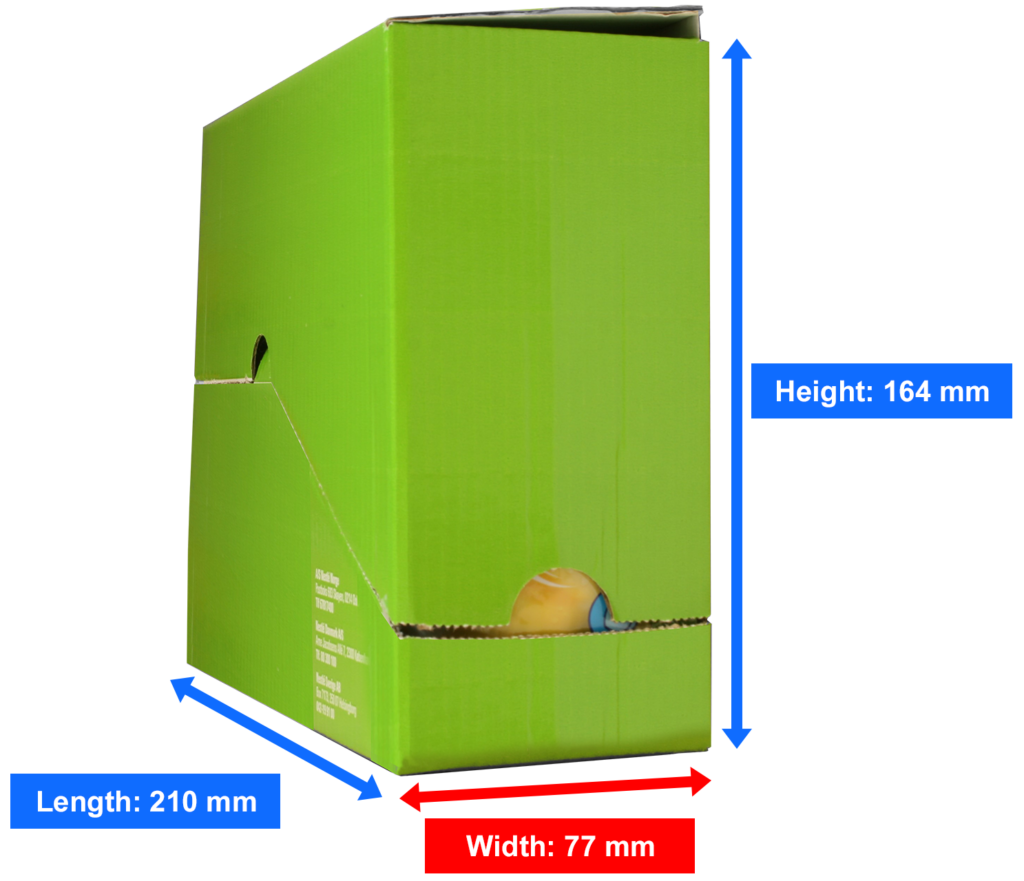

When designing a Stock Keeping Unit (SKU), it must be based on the modular system.

This means that the Stock Keeping Unit (SKU) should not be less than 100 x 150 mm and not more than 400 x 600 mm.

Example of best practices

Modular Stock Keeping Unit (SKU).

Example of an inappropriate Stock Keeping Unit (SKU)

Stock Keeping Unit (SKU) is not adapted to the modular system.

The size of the Stock Keeping Unit (SKU) must consider the size of the shelf space for the current product group.

The short side of the Stock Keeping Unit (SKU) should be front where appropriate.

There must be a simple and clear opening guide, preferably with illustration.

The packaging must be opened without using a knife.

When the Consumer Units (CU) is exposed in the Stock Keeping Unit (SKU), the least possible of the Stock Keeping Unit’s (SKU) packaging should be visible when exposed in the store shelf.

Stock Keeping Unit (SKU) must not weigh more than 15 kg.

Stock Keeping Unit (SKU) must be in recyclable cardboard or plastic.

Example of an inappropriate Stock Keeping Unit (SKU)

Lid / plastic film is missing, which may cause Consumer Unit (CU) to fall out during internal transport.

Plastic boxes – all variants – must be considered to work in automated warehouse handling.

Stock Keeping Unit (SKU) must be form stable.

Example of best practices

Stock Keeping Unit (SKU) is form stable.

Example of best practices

Form stable Stock Keeping Units (SKU) that embraces close to its content and is strong enough to not deform.

Resists load on inbound transport (2 pallets in height), as well as handling through the value chain.

Example of an inappropriate Stock Keeping Unit (SKU)

Not form stable. Do not resist strain on inbound transport (2 pallets in height), as well as handling through the value chain.

Stock Keeping Unit (SKU) that is only wrapped in plastic foil must have a tray / trough below.

Example of best practices

Stock Keeping Unit (SKU) on tray / trough with plastic wrap.

Stock Keeping Units (SKU) must have straight sides.

Example of best practices

Stock Keeping Units (SKU) with straight sides.

Glue quality and amount of glue on Stock Keeping Unit (SKU) must be such that glued surfaces do not loosen.

Example of best practices

Glue quality and amount of glue is such that glued surfaces do not loosen.

Constructed example of an inappropriate Stock Keeping Unit (SKU)

Too little glue / too few glue points are included that flap gaps with subsequent stops in automatic warehouse systems.

The Stock Keeping Unit (SKU) should be stackable and “ears” should only be used where it is necessary for stability.

Should “ears” be used, these should not exceed 5mm and should not be used in conjunction with intermediate pallet sheets.

Stock Keeping Unit (SKU) should not have loose lid.

The lid must be attached to the tray / trough in such a way that it does not loosen during handling. It is recommended to use glue points or a locking mechanism.

The Stock Keeping Unit (SKU) must have a center of gravity relative to the base that allows it to be handled on conveyor belts.

The height / width ratio should be below 1.7 to ensure that the products do not fall under internal transport in an automatic warehouse.

Example of best practices

The ratio height / width is below 1.7.

Example of an inappropriate Stock Keeping Unit (SKU)

The height / width ratio is over 1.7, which means that the Stock Keeping Unit (SKU) can fall during internal transport.

Stock Keeping Unit (SKU) exposure front should not be less than 30 mm, regardless of the chosen solution.

The information on the Consumer Unit (CU) must be visible.

Packaging capacity

During the design of the product and packaging it must be considered that the outer dimensions of the finished Stock Keeping Unit (SKU), tray and otherwise, under the load of the above-mentioned product packaging, due to bulging, is within the margin. In practice, this can be from 0.5 to 1.0 cm.

Optimal transport requires the use of load capacity of the transport systems (weight and height).

Generally, the packaging should be able to carry a similar pallet (2 identical pallets) without any breakage or clamping damage during transport and storage.

Exceptions from this must be specified and labelled on the (Distribution Unit (DU).

Method of calculation of carrying capacity is described in Top load labelling system.

The packaging shall be able to withstand shipping with other products for shipping to the store in a rational way.

In order to achieve the industry’s common goal of efficient flow of products, reduced negative environmental impact, promoted sales and reduced losses, it is important to focus on:

- Top load

- Stackability

- Module customization

Especially for reusable boxes / pallet boxes

Basically, Stock Keeping Units (SKU) is desired in cardboard, or in combination with plastic.

Reusable boxes are an alternative to Stock Keeping Units (SKU) in corrugated paper but must be agreed bilaterally.

Particularly for Intermediate cartons

The use of Intermediate cartons should be kept as low as possible and must be agreed bilaterally.

Intermediate cartons are accepted in cases where the Stock Keeping Unit (SKU) solution is not possible because the Stock Keeping Unit (SKU) does not meet the requirements for strength, stability or size and where the use of intermediate pallet sheet on pallet is not possible.

The intermediate carton must be labelled so that it clearly differs from the Stock Keeping Unit (SKU) and shall not weigh more than 15 kg.

170 Requirements for design of Consumer Unit (CU)

Requirements for design of Consumer Unit (CU)

Consumer Unit (CU) is the unit the consumer purchases in store.

Consumer Unit (CU) must be designed to optimize use of shop shelves and other furnishings. In addition, the information on the Consumer Unit (CU) should be visible even when the package is on a tray on the shelf.

Consumer Unit (CU) should be easy to open and to use.

Consumer Unit (CU) should be, included Stock Keeping Unit (SKU) and Distribution Unit (DU) adapted to the modular system, see Modular system

Unnecessary volume not containing the product itself in the packaging should be limited to what is necessary to protect the product. If necessary, secure against shrinkage (small, valuable Consumer Units (CU)).

Quantity (packing content) in Consumer Unit (CU) is determined by manufacturer, preferably in dialogue with distributor / retail chain.

Case fill rate shall be calculated. This is described in Case fill rate

On new products, it is expected that the case fill rate is higher than the average of the product group to which it belongs.

Measurement of the case fill rate related to the product launch windows was carried out by DMF until 2018. When switching to a new product classification system, historical data could not be compared, as the timeline and product groupings from 2014 were changed.

Efforts to increase the case fill rate in the grocery industry are important from both an environmental and efficiency perspective.

In collaboration with the industry, Tradesolution has developed some new reports for measuring the case fill rate in the grocery industry. Suppliers and retailer chains that have access to the EPD base can see the case fill rate for the products they have access to directly in the database. Here you can see the actual case fill rate on basic product (BASIS-level) and calculated case fill rate for the packaging levels above.

Log in her and feel free to contact the EPD base helpdesk at epd@tradesolution.no if you have further questions.

169 Optimization of Consumer Unit (CU), Stock Keeping Unit (SKU), Distribution Unit (DU) and packaging – central to the development of new/changes to existing products

Optimization of Consumer Unit (CU), Stock Keeping Unit (SKU), Distribution Unit (DU) and packaging – central to the development of new/changes to existing products

The grocery industry has a common goal of being able to:

- Streamline product flow

- Reduce environmental impact

- Promote sales

- Reduce shrinkage

when products are being developed/changed.

To achieve this, it is crucial to standardize and optimize packaging on the product at all packaging levels – Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU).

STAND has therefore prepared a standard for this, which applies to all packaging levels.

Audience for the standard is managers and everyone who works with product development, assortment and logistics in the value chain.

By complying with the standard, processes in the value chain are optimized and gains can be extracted in a number of areas such as:

Warehouse

- Form Stable Distribution Units (DU) and Stock Keeping Units (SKU)

- Correct quality of Distribution Units (DU) and Stock Keeping Units (SKU) for efficient handling through warehouse

Outbound transport

- Withstand double stacking

- Avoids shrinkage and damage

Inbound transport

- High case fill rate

- Double stacking of pallets

- Avoiding transport damage

Shop

- Effective replenishment

- Sales-friendly, good visibility when Stock Keeping Unit (SKU) is used to expose products

- Optimal use of shelf space

- Reduced food waste, with correct number of Consumer Units (CU) in Stock Keeping Unit (SKU)

- Reduced food waste, utilising 2D barcodes with dynamic information

Consumer

- Optimal and user-friendly packaging

- Clear, accurate and complementary product declaration

- Recycling labelling

- Extended product information utilising 2D barcodes

In addition, optimization of packaging through compliance with the standard will reduce environmental impact at all stages in the value chain, as part of the industry agreement with the authorities.

The packaging must be:

Easy to sort

In order for the packaging to be able to be recycled, it is important that it is sorted correctly by the end user and thus enters the correct recycling stream. There are a number of steps you can take when designing the packaging, which increase the likelihood that it will be sorted correctly. This information is summarized at https://www.grontpunkt.no/design-for-kildesortering

Recyclable

In order for the packaging to be material-recycled and become new raw material that can be used to make new products, it is important that this is taken into account in the packaging design and material selection. To find out how recyclable the packaging is and what steps can be taken to improve this, you can enter the packaging in https://kalkulator.grontpunkt.no

In monomaterial if possible

The easiest way to make it more intuitive for the end user to sort the packaging correctly, and to make it easier to recycle the packaging, is to ensure that the packaging only consists of one material.

From recycled material if possible

Most packaging is recycled, but there is too little demand for recycled material. By using recycled material when developing new packaging, you ensure that the circular material flows work and thus both reduce the need for virgin raw material and the environmental burdens these entail.

Important notice

All products must follow the GS1 Allocation rules. (chapter 2.4). These are international rules and are mainly based on the fact that a change of over 20% to a physical dimension, on any axis, or gross weight, requires assignment of a new GTIN.

In addition, the following applies to Norway:

- For products registered in the Tradesolution EPD base, approval of the grocery chains is required to keep existing GTIN on a product, also for changes below 20%

- Frequent cumulative changes, without changing the GTIN, in avoidance of the 20% rule is an unacceptable practice. Trading partners should be notified about all dimensional changes. Cumulative changes might cause problems for trading partners and may obstruct the transport and supply of a product

- Local, national or regional regulations may require more frequent GTIN changes. Such regulations have precedence over the rules provided within the GTIN Management Standard

Exception from the standard

Under special conditions, exceptions from industry standards and guidelines may be relevant.

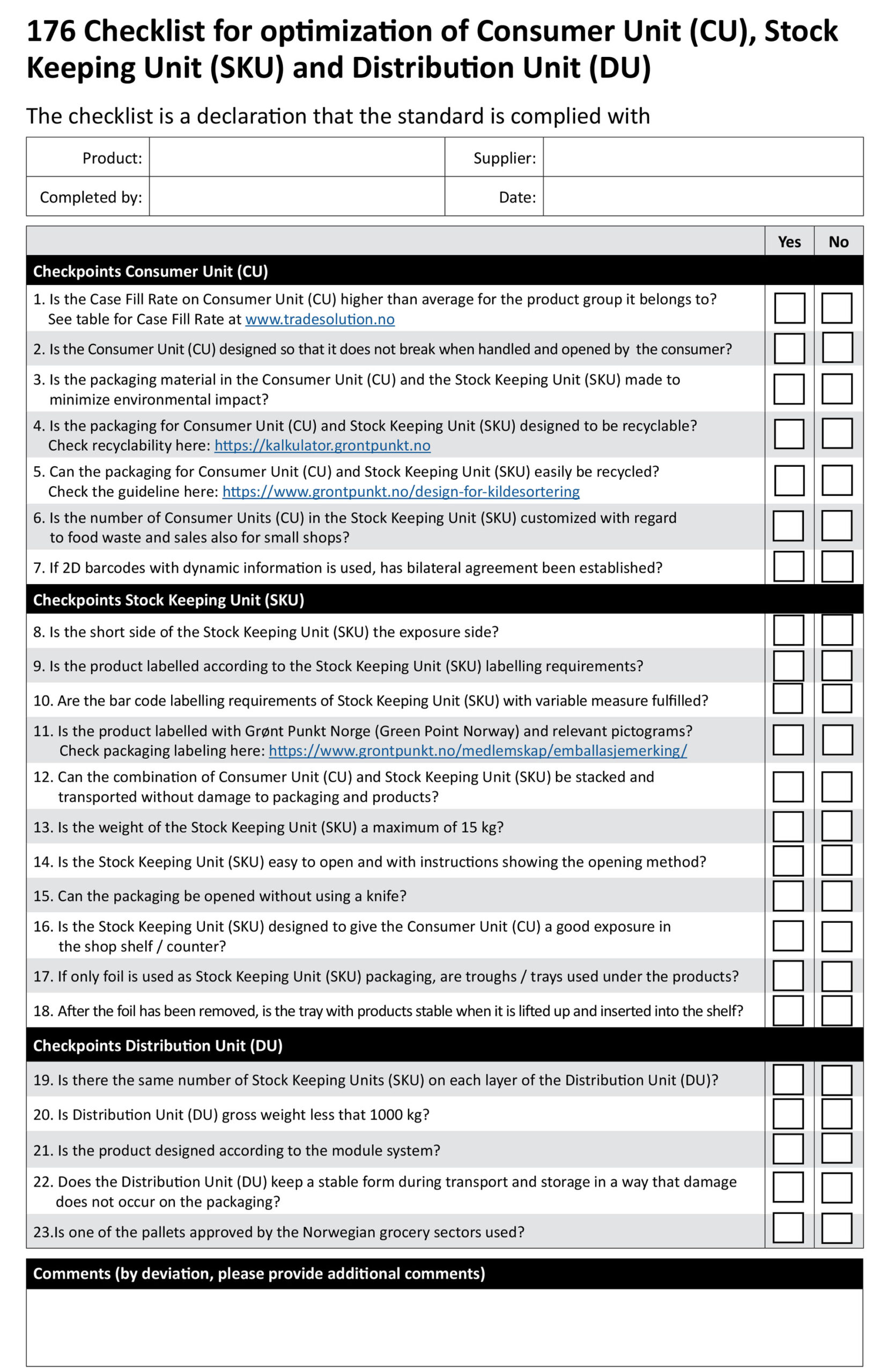

Exceptions must be agreed separately between the parties concerned and shall be described in Checklist for optimization of Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU).

The check list can be downloaded as a separate document.

Mandate

MANDATE AND ROLE FOR STAND – STANDARDIZATION COMMITTEE FOR THE NORWEGIAN GROCERY SECTOR

Background

The committee was established in 1998.

The committee consists of four representatives and four substitute members from each of the organizations DLF (Grocery suppliers of Norway) and DMF AS (Norwegian Grocery Sector’s Environmental Forum). In addition, GS1 Norway has a role as observer. The leader and secretariat are allocated to DLF and DMF and rotate every second year.

The committee has prepared recommendations for the grocery industry, which can be found on STAND’s website www.stand.no .

Mandate

STAND will develop and recommend relevant framework and guidelines contributing to sustainable and effective supply chains in the Norwegian grocery sector*.

This includes topics relevant for the flow of goods and information, such as:

- Shared master data, transactions, eCOM, and track & trace

- Packaging and labelling

- Load carriers and distribution

Matters related to sustainability and food waste must be emphasized in particular.

The committee’s work should as far as possible be based on international standards.

STAND’s recommendations, in terms of standards and guidelines, will be valid when incorporated in the bilateral agreements between the parties.

* The guidelines are developed for use within the grocery sector. Relevant topics are also suitable for use within convenience and catering.

Form of cooperation

- STAND operates its activities according to a continuous work program. DLF and DMF propose suggestions on issues that need to be addressed. STAND will strive to ensure that all issues of common interest affecting the entire value chain from manufacturer to consumer are coordinated through STAND. Project and working groups are created are established when needed. If either DLF or DMF want to conduct an internal project before it is presented to STAND, then the counterparty should be informed of this work as early as possible.

- STAND produces its own recommendations and coordinates external recommendations that require the approval of DLF and DMF.

- STAND puts approved recommendations into practice by publishing on the internet and seminars. The recommendations have a common design to make it clear that they are approved by DLF and DMF.

The standardization process

The standards must be of high quality and developed to be generally accepted in the grocery industry. The work is based on the following routines for the preparation, implementation and follow-up of all recommendations:

- STAND defines the work and establishes a project or workgroup

- Determining the purpose of the standard

- Evaluation of cost/benefit of the initiative.

- Anchoring of interested parties through hearings

- Quality assurance in DLF and DMF’s workgroups

- Determination of implementation date for new standards

- Audits will be completed by 1st September and published

- STAND approves the standard and recommends approval by DLF and DMF

The standards must be open and voluntarily in the grocery industry. STAND’s activities and recommendations must always be within the framework of current competition law.

Finance

Each party cover their own costs of participation in STAND.

Projects launched by STAND are financed equally by industry and retail, invoiced by Tradesolution.

Possible participation in international forums on behalf of STAND is agreed separately.

Coordination in the industry

There are currently several persons and committees working with standardization within, or in connection with the grocery value chain. STAND has the responsibility to make the best use of resources through coordinating inputs and ideas, avoiding duplication and strengthening implementation through focusing on measures by uniformly recognizable presentation.

STAND’s standards are posted on the website and other standards such as GS1 are linked from STAND’s website, so industry representatives can find unified standards and guidelines via one single point of entry: www.stand.no

Approved by the board in DMF 30.6.05 and by the board in DLF 31.8.05.

Latest revised September 2023.

The parties may make changes to the mandate if necessary.

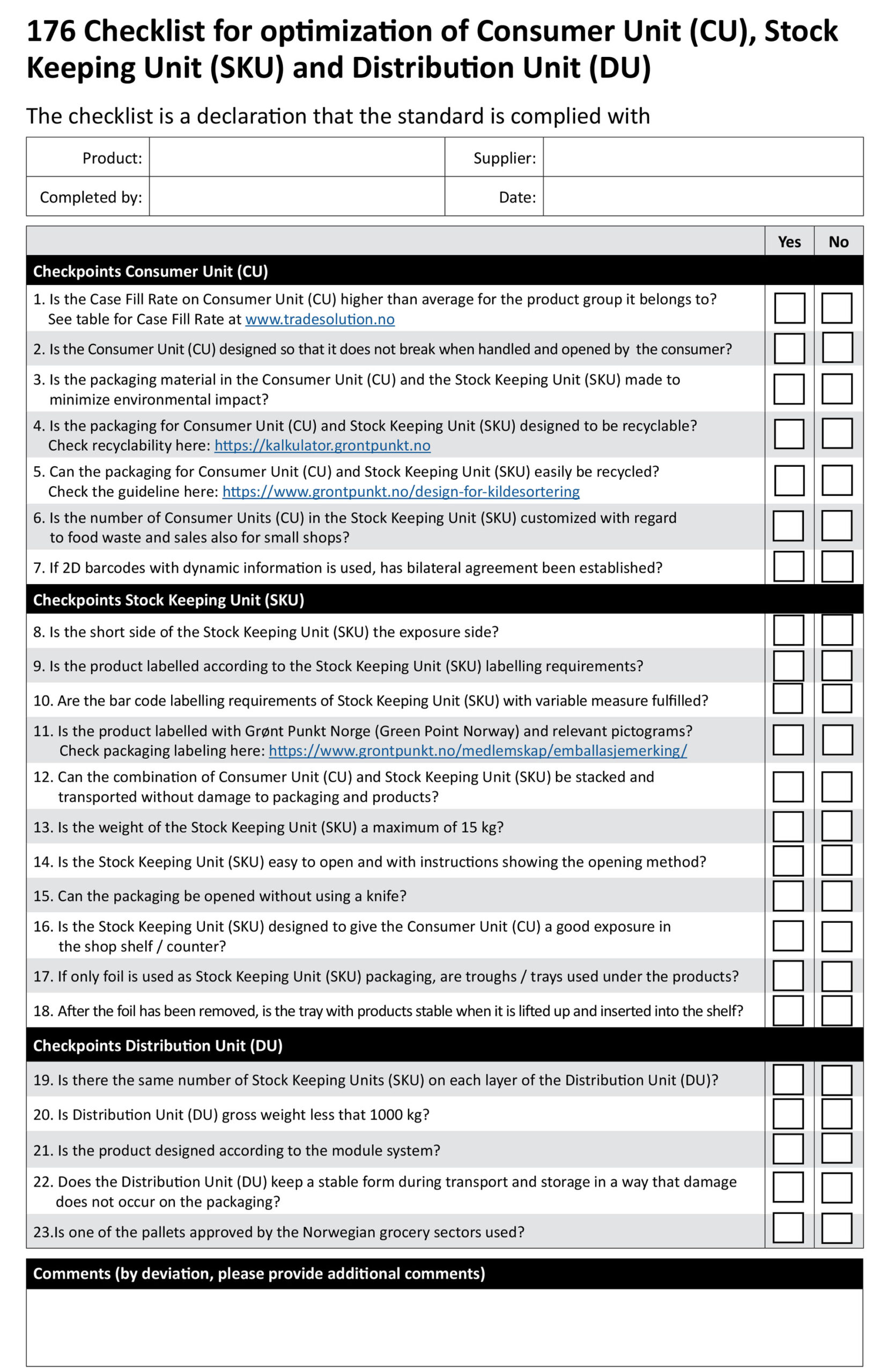

176 Checklist for optimization of Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU)

Checklist for optimization of Consumer Unit (CU), Stock Keeping Unit (SKU) and Distribution Unit (DU)

The checklist is a declaration that the standard is complied with

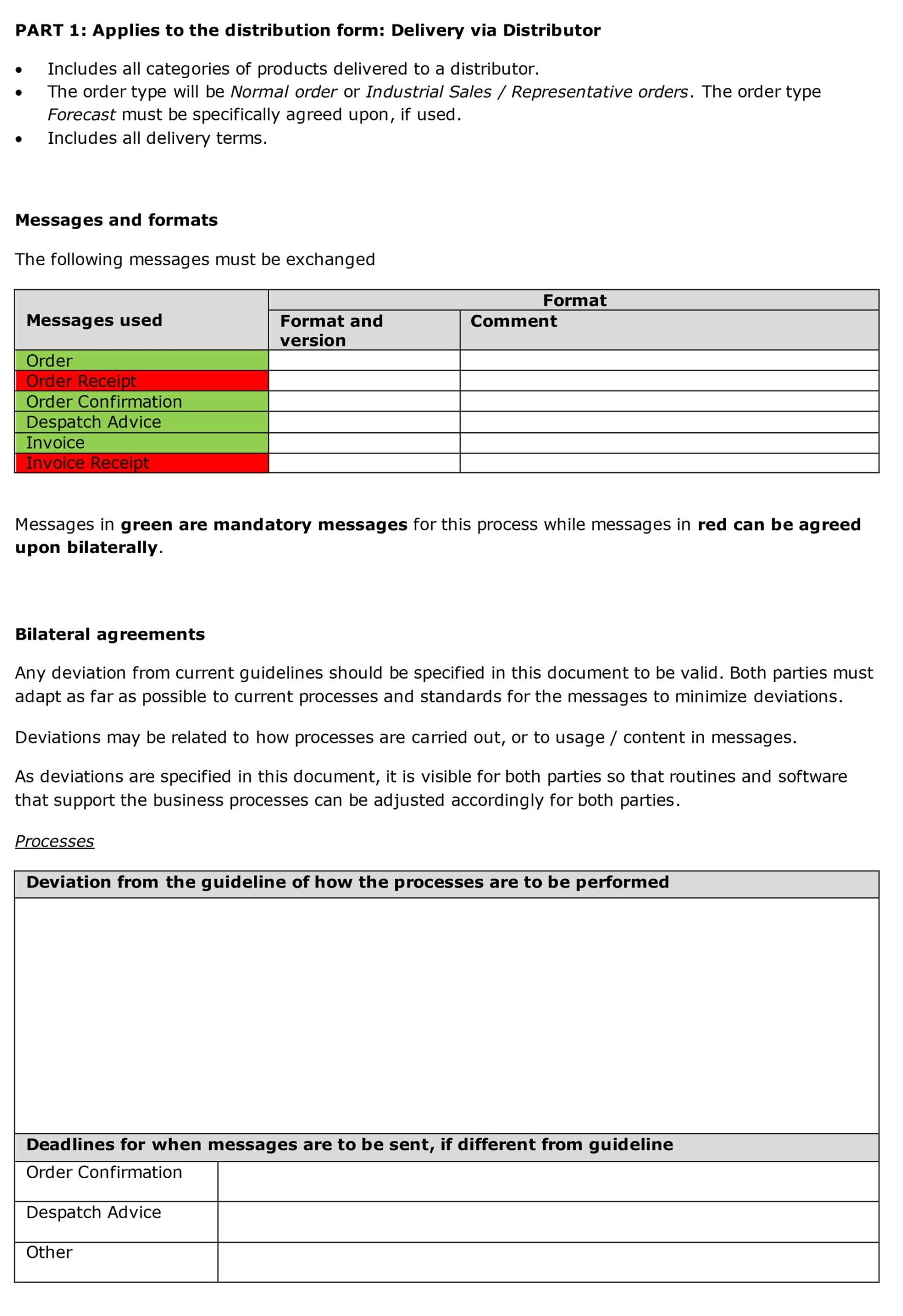

205 EDI Exchange Agreement

EDI Exchange Agreement

Download the exchange agreement here

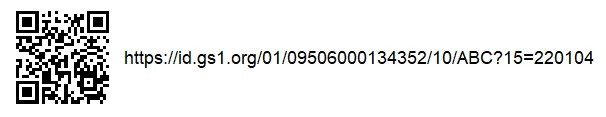

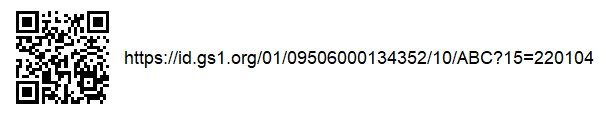

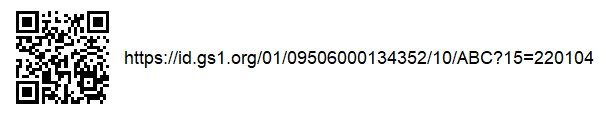

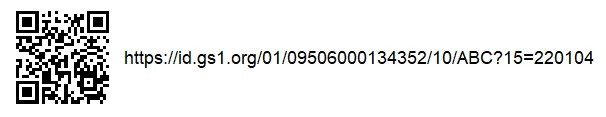

322 QR code with GS1 Digital Link

Barcode syntax

The use of GS1 Digital Link

GS1 Digital Link is a standard that has been developed to give consumers an opportunity to find more information about a product by reading the barcode on an item with their mobile phone. GS1 Digital Link can also provide manufacturers with information about where the product is read, in which situations it is read and other additional information about consumer behaviour.

The GS1 Digital Link standard defines several ways to do this.

One can either have an app that is connected to a resolver (a kind of translator) that interprets the content of the barcode and adapts it to what desire or need there is for information in the setting the barcode is read. If you use a resolver, you can read all types of barcodes that contain a GS1 identifier (GTIN, GLN, SSCC, etc.).

You can also use the mobile phone’s built-in camera app to read barcodes that contain a GS1 Digital Link structure, but this sets requirements for the type of barcode used. To be sure that all smartphones on the market can interpret the information, one should use QR Code. This is the barcode type supported by most phones.

In the barcode you enter a URL in addition to GTIN and any additional attributes.

When the barcode is read by the camera app on a smartphone, you will be routed to the website with information about the product that is entered in the barcode.

If you use an app with a resolver, the URL that is entered in the barcode can be replaced with the URL that is entered in the resolver so that the reader can get the corrected information depending on which options are available in the app used.

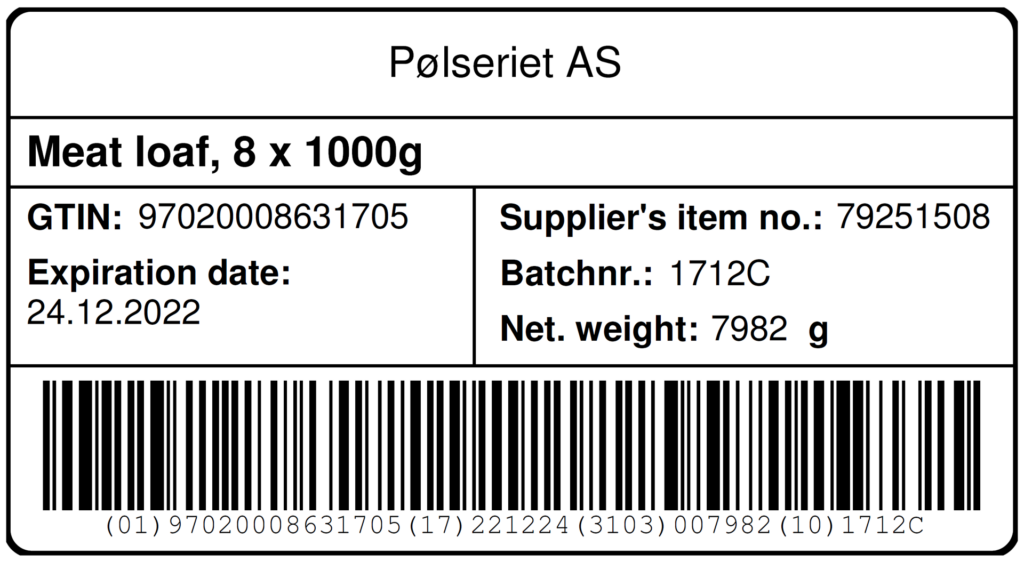

The physical size of a 2D barcode varies according to the amount of information contained in it. The resolution of the barcode (X-dimension) must be a minimum of 0.375mm and a maximum of 0.990mm when using GS1 AI syntax in the barcode on Consumer unit.

The resolution of the barcode (X-dimension) must be a minimum of 0.396 and a maximum of 0.990mm when using GS1 Digital Link URI syntax in the barcode on consumer unit.

Quality and life span of the barcode

2D barcodes are verified according to the ISO standard ISO / IEC 15415. This is an international standard that describes the quality requirements for barcodes and how easy they are to read. Highest grade is 4.0 / 20/660. The minimum requirement is 1.5 / 20/660. The numbers indicate; character / aperture / wavelength of the light illuminating the barcode.

The service life of a barcode depends on the type of label material used and where / how the label is placed on the product. Label material / printing method must be chosen that has at least as long a shelf life as the assessed shelf life of the product to be labelled.

Placement of the barcode on the product

If 2 barcodes are placed on the product, a linear and a 2D barcode for use in POS or a linear and a GS1 Digital Link for consumer engagement or two 2D barcodes for both POS and consumer engagement, efforts should be made to place them adjacent on the packaging. This ensures that the barcode is read regardless of which barcode contains what you want to read. Programming the barcode scanners to ignore the type of code that should not be read will prevent erroneous readings.

Readability of the barcode

The readability of the barcode depends on the size of the barcode, the type of barcode reader and the distance from the barcode to the barcode reader. If the requirements for size and quality are followed, this is in accordance with industry standards and the barcodes can be read at a normal distance with normal equipment.

QR Code with GS1 Digital Link syntax for consumer engagement

For those manufacturers who wish to have a structured way of communicating with consumers, it is QR Code with GS1 Digital Link structure that should be used. By using GS1 Digital Link structure with GTIN coded in, it opens for all links in the value chain to provide targeted information to the person scanning the barcode. The consumer can obtain all available information from the manufacturer and / or the trade link. This is a barcode that can be read by most smartphones with its built-in camera app. In addition, consumers are used to the fact that QR Code can be read with the smartphone and give them more information. By splitting the information to be used for POS purposes and consumer-oriented communication, the QR Code with information to the consumer can also be pre-printed on the packaging and this will reduce the need for changes to the production equipment.

QR Code with consumer-oriented information can also be placed on the packaging together with the current EAN-13 barcode where it is not yet possible or desirable to have a 2D barcode with dynamic information for POS purposes.

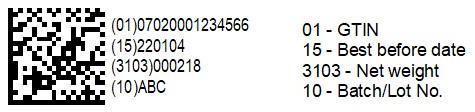

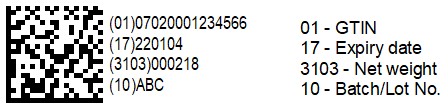

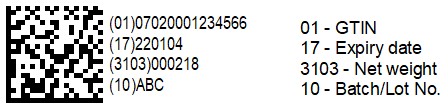

321 GS1 Datamatrix Element String barcode

Barcode syntax – The use of GS1 Element String (Application Identifiers (AI))

GS1 application identifiers (AI) are numeric prefixes used in barcodes to define the meaning of and syntax of information elements. AIs makes it possible to separate different information elements from one another in a barcode. In the text below or next to a barcode, these appear as numbers in parentheses and the content of the individual AI follows accordingly. A GS1 barcode is required to use AIs.

GS1 has defined over 100 application identifiers (AIs). Each application identifier is a standard two-, three- or four-digit number code. For the full list of GS1 application identifiers and their definitions, see section 3.2 of the GS1 General Specification.

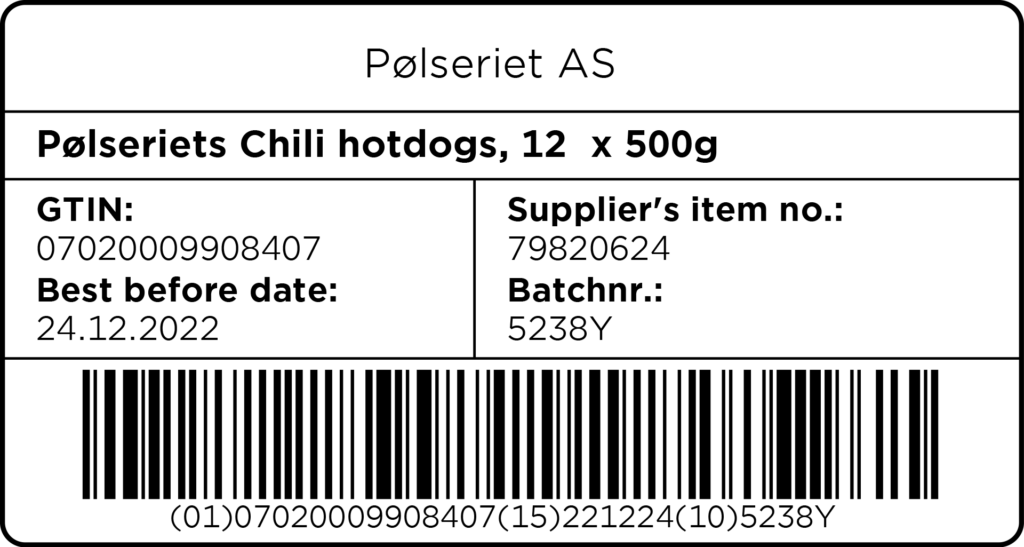

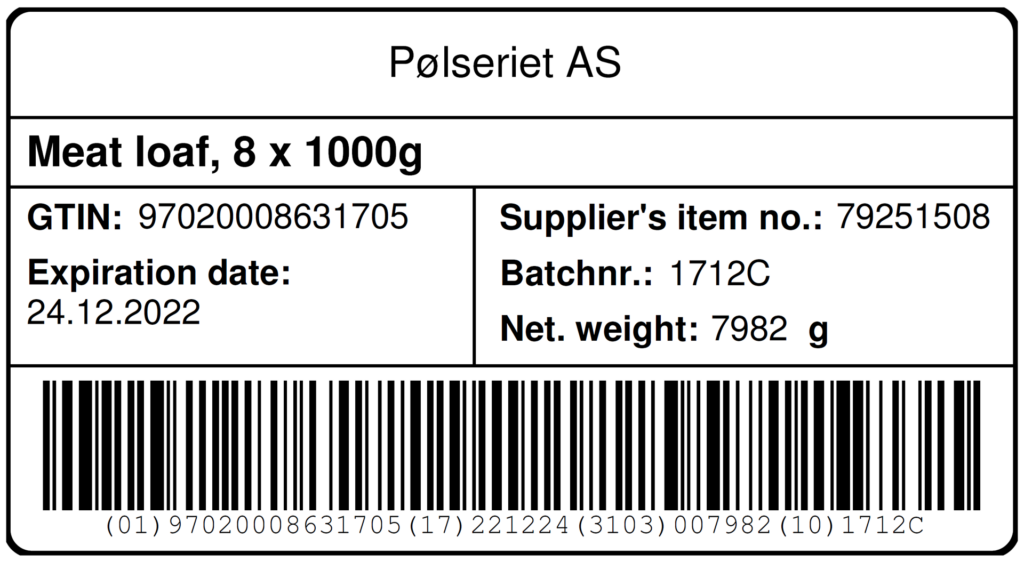

Barcode with AI 15 for «Best before date».

Barcode with AI 17 for «Expiry date».

Barcode size

The physical size of a 2D barcode varies according to the amount of information contained in it. The resolution of the barcode (X-dimension) must be a minimum of 0.375mm and a maximum of 0.990mm when using GS1 AI syntax in the barcode on a consumer unit.

The resolution of the barcode (X-dimension) must be a minimum of 0.396 and a maximum of 0.990mm when using GS1 Digital Link URI syntax in the barcode on a consumer unit.

Barcode quality and life span

2D barcodes are verified according to the ISO standard ISO / IEC 15415. This is an international standard that describes the quality requirements for barcodes and the readability. Highest grade is 4.0 / 20/660. The minimum requirement is 1.5 / 20/660. The numbers indicate; character / aperture / wavelength of the light illuminating the barcode.

The life span of a barcode depends on the type of label material used and where / how the label is placed on the product. Label material / printing method must be chosen that has at least as long a shelf life as the assessed shelf life of the product to be labelled.

Placement of the barcode on the product

If 2 barcodes are placed on the product, a linear and a 2D barcode for use in POS or a linear and a GS1 Digital Link for consumer communication or two 2D barcodes for both POS and consumer communication, efforts should be made to place them adjacent on the packaging. This ensures that the barcode is read regardless of which barcode contains what you want to read. Programming the barcode scanners to ignore the type of code that should not be read will prevent erroneous readings.

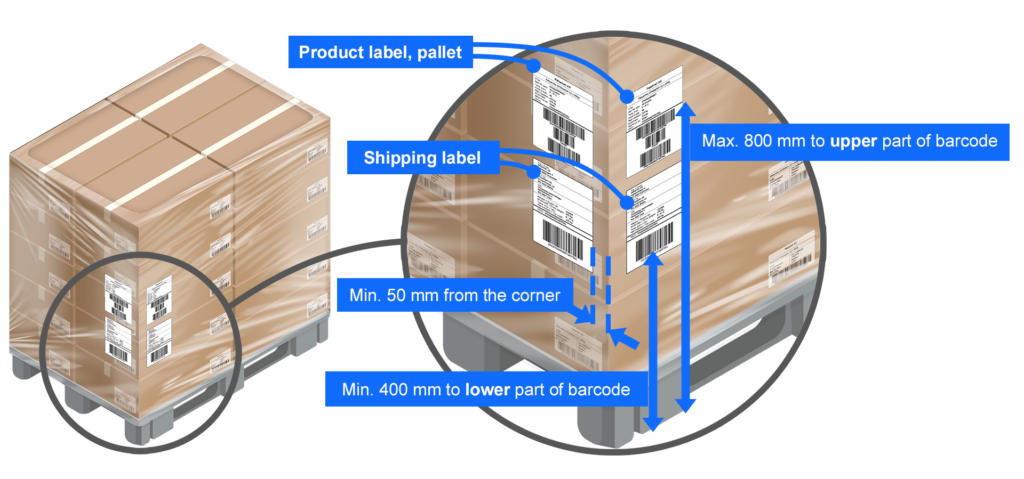

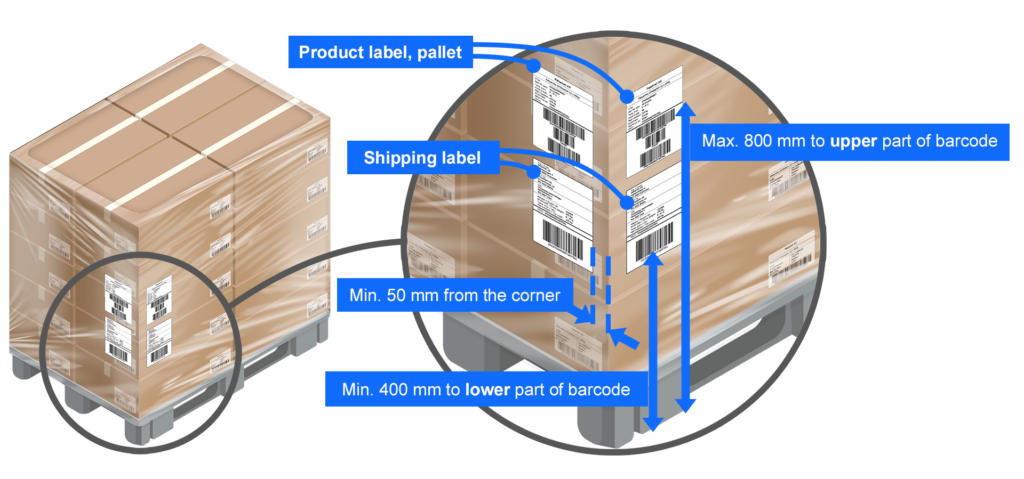

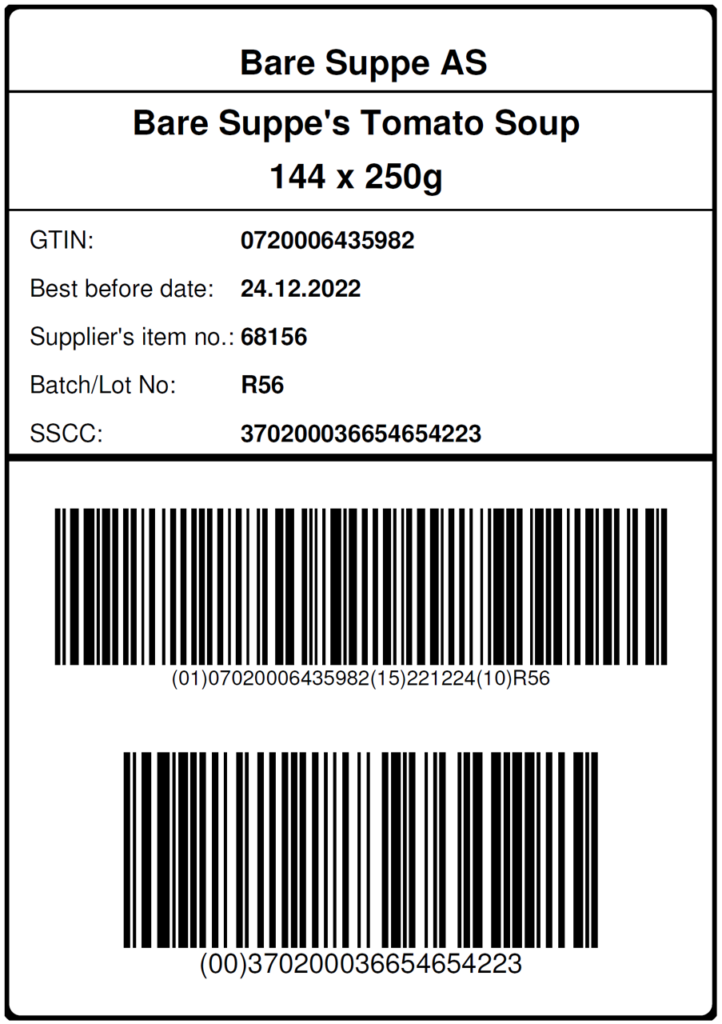

Readability of the barcode