Requirements for design of Stock Keeping Unit (SKU) and packaging

Stock Keeping Unit (SKU) is the unit the retailer buys.

Stock Keeping Unit (SKU) occurs in various forms, such as carton, reusable box / pallet box, intermediate carton and such.

The most important task of the Stock Keeping Unit (SKU) is to secure Consumer Units (CU) from the time of manufacturing until it is finished exposed in a shop shelf.

The number of Consumer Units (CU) in a Stock Keeping Unit (SKU) is determined by the manufacturer, preferably in dialogue with the distributor / retail chain.

The Stock Keeping Unit (SKU) must be adapted to the modular system, see Modular system

for picking and grouping of products can be done as efficient as possible.

Case fill rate shall be calculated. This is described in Case fill rate

Stock Keeping Unit (SKU) must be designed to withstand the strain required in the value chain.

Automatic warehouses require that Stock Keeping Units (SKU) must be packed in a way that it can be lifted, stacked, clamped and handled with different mechanized devices, see Automated warehouse at distributor – greater understanding of the depalletization process.

Design requirements and packaging

When designing a Stock Keeping Unit (SKU), it must be based on the modular system.

This means that the Stock Keeping Unit (SKU) should not be less than 100 x 150 mm and not more than 400 x 600 mm.

Example of best practices

Modular Stock Keeping Unit (SKU).

Example of an inappropriate Stock Keeping Unit (SKU)

Stock Keeping Unit (SKU) is not adapted to the modular system.

The size of the Stock Keeping Unit (SKU) must consider the size of the shelf space for the current product group.

The short side of the Stock Keeping Unit (SKU) should be front where appropriate.

There must be a simple and clear opening guide, preferably with illustration.

The packaging must be opened without using a knife.

When the Consumer Units (CU) is exposed in the Stock Keeping Unit (SKU), the least possible of the Stock Keeping Unit’s (SKU) packaging should be visible when exposed in the store shelf.

Stock Keeping Unit (SKU) must not weigh more than 15 kg.

Stock Keeping Unit (SKU) must be in recyclable cardboard or plastic.

Example of an inappropriate Stock Keeping Unit (SKU)

Lid / plastic film is missing, which may cause Consumer Unit (CU) to fall out during internal transport.

Plastic boxes – all variants – must be considered to work in automated warehouse handling.

Stock Keeping Unit (SKU) must be form stable.

Example of best practices

Stock Keeping Unit (SKU) is form stable.

Example of best practices

Form stable Stock Keeping Units (SKU) that embraces close to its content and is strong enough to not deform.

Resists load on inbound transport (2 pallets in height), as well as handling through the value chain.

Example of an inappropriate Stock Keeping Unit (SKU)

Not form stable. Do not resist strain on inbound transport (2 pallets in height), as well as handling through the value chain.

Stock Keeping Unit (SKU) that is only wrapped in plastic foil must have a tray / trough below.

Example of best practices

Stock Keeping Unit (SKU) on tray / trough with plastic wrap.

Stock Keeping Units (SKU) must have straight sides.

Example of best practices

Stock Keeping Units (SKU) with straight sides.

Glue quality and amount of glue on Stock Keeping Unit (SKU) must be such that glued surfaces do not loosen.

Example of best practices

Glue quality and amount of glue is such that glued surfaces do not loosen.

Constructed example of an inappropriate Stock Keeping Unit (SKU)

Too little glue / too few glue points are included that flap gaps with subsequent stops in automatic warehouse systems.

The Stock Keeping Unit (SKU) should be stackable and “ears” should only be used where it is necessary for stability.

Should “ears” be used, these should not exceed 5mm and should not be used in conjunction with intermediate pallet sheets.

Stock Keeping Unit (SKU) should not have loose lid.

The lid must be attached to the tray / trough in such a way that it does not loosen during handling. It is recommended to use glue points or a locking mechanism.

The Stock Keeping Unit (SKU) must have a center of gravity relative to the base that allows it to be handled on conveyor belts.

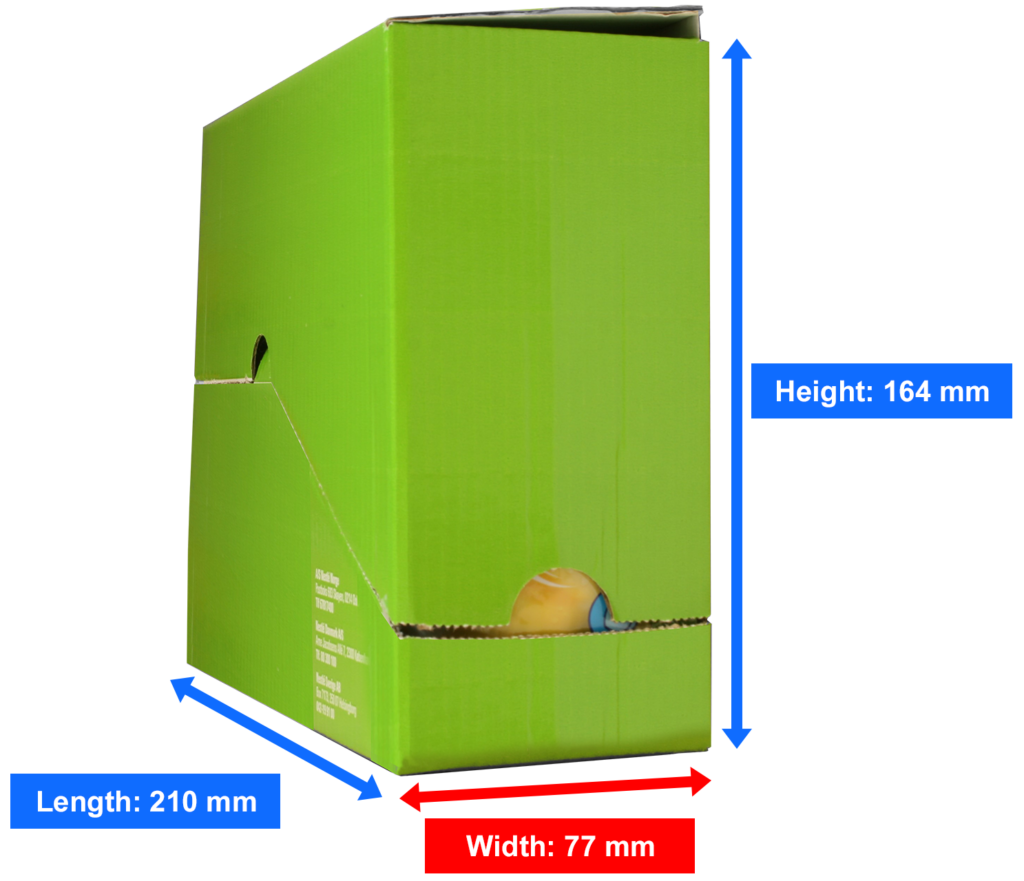

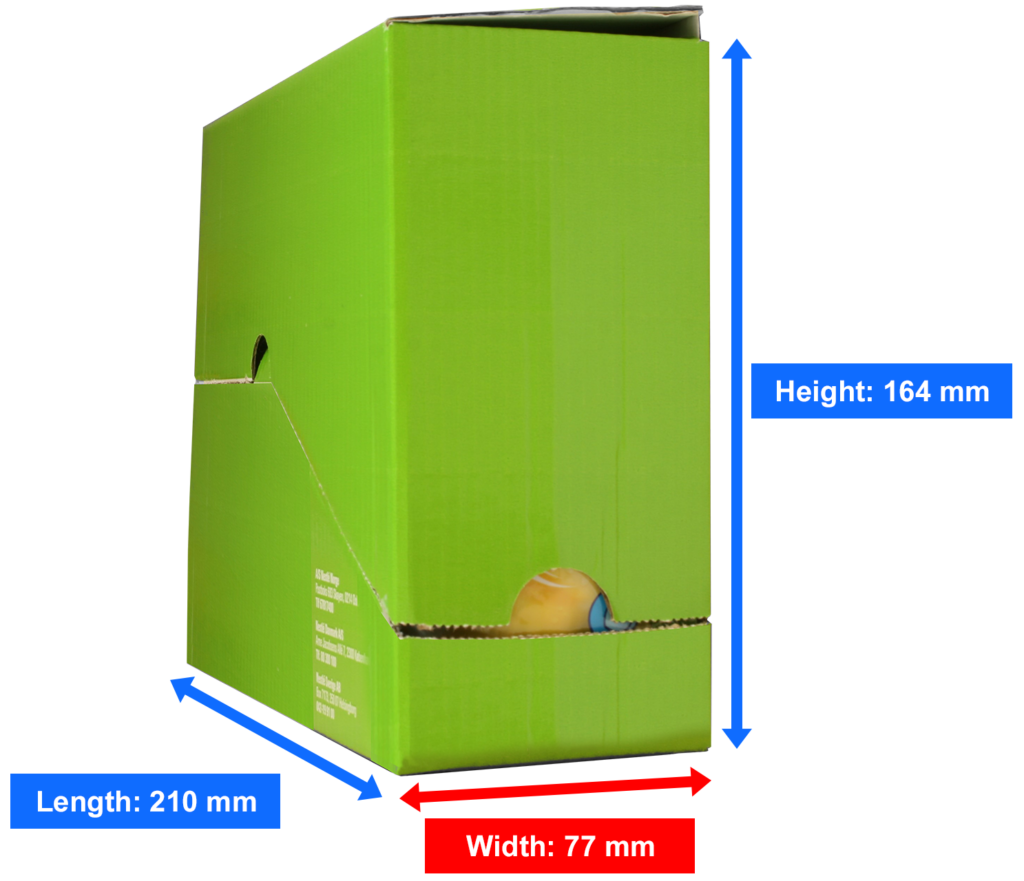

The height / width ratio should be below 1.7 to ensure that the products do not fall under internal transport in an automatic warehouse.

Example of best practices

The ratio height / width is below 1.7.

Example of an inappropriate Stock Keeping Unit (SKU)

The height / width ratio is over 1.7, which means that the Stock Keeping Unit (SKU) can fall during internal transport.

Stock Keeping Unit (SKU) exposure front should not be less than 30 mm, regardless of the chosen solution.

The information on the Consumer Unit (CU) must be visible.

Packaging capacity

During the design of the product and packaging it must be considered that the outer dimensions of the finished Stock Keeping Unit (SKU), tray and otherwise, under the load of the above-mentioned product packaging, due to bulging, is within the margin. In practice, this can be from 0.5 to 1.0 cm.

Optimal transport requires the use of load capacity of the transport systems (weight and height).

Generally, the packaging should be able to carry a similar pallet (2 identical pallets) without any breakage or clamping damage during transport and storage.

Exceptions from this must be specified and labelled on the (Distribution Unit (DU).

Method of calculation of carrying capacity is described in Top load labelling system.

The packaging shall be able to withstand shipping with other products for shipping to the store in a rational way.

In order to achieve the industry’s common goal of efficient flow of products, reduced negative environmental impact, promoted sales and reduced losses, it is important to focus on:

- Top load

- Stackability

- Module customization

Especially for reusable boxes / pallet boxes

Basically, Stock Keeping Units (SKU) is desired in cardboard, or in combination with plastic.

Reusable boxes are an alternative to Stock Keeping Units (SKU) in corrugated paper but must be agreed bilaterally.

Particularly for Intermediate cartons

The use of Intermediate cartons should be kept as low as possible and must be agreed bilaterally.

Intermediate cartons are accepted in cases where the Stock Keeping Unit (SKU) solution is not possible because the Stock Keeping Unit (SKU) does not meet the requirements for strength, stability or size and where the use of intermediate pallet sheet on pallet is not possible.

The intermediate carton must be labelled so that it clearly differs from the Stock Keeping Unit (SKU) and shall not weigh more than 15 kg.