8. Data Sharing

8.1 Background

The industry agreement on reducing food waste was signed between the authorities and a unified food industry in June 2017. The goal of the agreement is to halve food waste in Norway by 2030, in line with the UN’s Sustainable Development Goals. A government-appointed Food Waste Committee delivered a report on January 3, 2024, with recommendations for new and enhanced measures to achieve the halving target. One of the recommended measures is standardized and increased data sharing in the value chain. STAND has developed this standard on behalf of the Food Waste Committee.

8.2 Purpose

The standard defines the format and exchange frequency for purchase forecasts from wholesalers to suppliers in the grocery industry. The purpose of the standard is to contribute to a significant reduction in food waste, as well as to improve the efficiency of goods and information flow in the industry. Furthermore, the standard aims for continuous improvement. This will be achieved through the exchange of defined KPIs and structured bilateral dialogue. To achieve these goals, it is also assumed that suppliers are capable of sending high-quality order confirmations to wholesalers. This means order confirmation down to the product line level and that the stated volume/quantity of products can be delivered at the desired delivery time. Regarding the exchange of other types of information between wholesalers and suppliers, such as the wholesaler’s sales to stores, POS data in stores, and inventory levels, this can be exchanged. This type of exchange is agreed upon and implemented bilaterally.

8.3 Scope

- The standard covers purchase forecasts from wholesalers to suppliers in the grocery industry. This means that direct distribution from suppliers to stores is not included in this standard.

- The purchase forecasts include grocery trade, kiosks, gas stations, convenience stores, and HoReCa (hotel, restaurant, and catering).

- The purchase forecasts from wholesalers are aggregated, i.e., total figures per wholesaler (chain).

- Purchase forecasts are specified uniformly for all product types and product shelf life. This means that all product categories and shelf life are treated equally in the standard.

- Purchase forecasts are provided at the article level, i.e., (SKU). The time horizon for purchase forecasts: The time horizon refers to the period up to the date the wholesaler retrieves the goods from the supplier (ex works).

- Part A: The forecast horizon is 13 weeks ahead. A purchase forecast from wholesaler to supplier must be provided for each week. This is given as a sum on a weekly basis.

- Part B: For the next three weeks, i.e., U-1, U-2, and U-3, purchase forecasts must be provided daily.

The purchase forecasts sent by the wholesaler to the supplier include:

a) Normal Sales: New products, phase-outs, and assortment changes should be included in the purchase forecast for normal sales. For new products, a clear distinction must be made between forecasts and orders.

b) Campaign Forecasts: Purchase forecasts for campaigns are included in the figures from wholesaler to supplier along with purchase forecasts for normal sales. To inform about purchase forecasts for campaigns, such as volume, it is recommended to exchange additional information between wholesaler and supplier. Note the handling of pre-orders. A pre-order means a physical order from the wholesaler to the supplier. The wholesaler has already sent the order. This should not be part of the purchase forecast.

c) Seasonal Products: Seasonal products are defined in STAND as “a product sold in a time-limited period related to a season defined by the parties involved.” A distinction is made here between seasonal products and contract sales. Seasonal products are characterized by being ordered from the wholesaler and delivered by the supplier continuously throughout the season. Seasonal products are included in the normal purchase forecast from wholesaler to supplier. Contract sales are characterized by an agreement being made for each product between the wholesaler and the supplier. For contract sales, a volume of the product to be delivered by the supplier to the wholesaler is locked in. Suppliers do not need purchase forecasts for contract sales. However, since no order has been sent from the wholesaler to the supplier, the contract sale for this product will appear as part of the purchase forecast sent by the wholesaler to the supplier. The supplier will then disregard the purchase forecast for these products

8.4 Exchange Frequency

The exchange frequency for purchase forecasts is weekly. More frequent exchanges can be agreed upon bilaterally for U-1, U-2, and U-3.

8.5 Exchange Format

Purchase forecasts from wholesaler to supplier are sent in Excel file format from wholesaler to supplier. The files are sent via email. There is no need for explicit identification of wholesaler and supplier in these emails. The emails are sent from/to email addresses that have been agreed upon in advance.

Two different files should be exchanged:

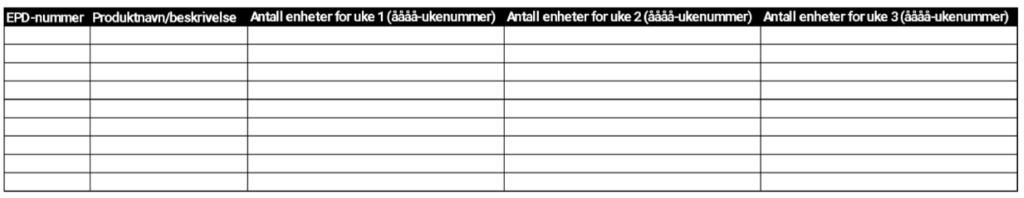

a. File A contains purchase forecasts per week for weeks 1 – 13. Column headers are EPD number, product description, number of units for the week number (year + calendar week).

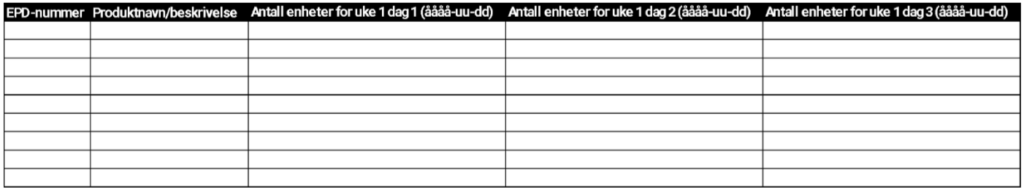

b. File B contains purchase forecasts per day for the next three weeks (U–1, U–2, and U–3). Column headers are EPD number, product description, number of units per day that the wholesaler retrieves from the supplier.

The content in the Excel sheets is specified as follows:

EPD number (File A and File B) identifies the ordering unit (D-pack) from wholesaler to supplier. See https://tradesolution.no/tjenester/epd/. Here, the EPD number is defined with 8 digits. Product name/description: It is recommended to use the same description as registered in the EPD database. Length is up to 30 alphanumeric characters.

Number of units per week: This refers to the number of ordering units (D-pack), unless otherwise agreed between the parties. Here, the number of units of the EPD number in the purchase forecast for weeks 1 – 13 is recorded. The week number is indicated with “year-week number” in the format “yyyy-ww” from week 1 to 13. There are 13 columns allocated.

Number of units per day: This refers to the number of ordering units (D-pack), unless otherwise agreed between the parties. Here, the number of units of the EPD number in the daily purchase forecast that the wholesaler retrieves from the supplier for the next three weeks U-1, U-2, U-3 is recorded. The day is indicated with year-month-day in the format “yyyy-mm-dd”. There are 15 columns allocated.

8.6 Continuous Improvement

To measure the effect of measures and ensure continuous improvement, relevant KPIs should be exchanged between the parties.

Primary KPI is forecast deviation – purchase forecast from wholesaler to supplier – to be exchanged

Forecast deviation is defined here as the purchase forecast from wholesaler to supplier measured against the actual order from wholesaler to supplier per D-pack (SKU). Frequency can vary. Goals and thresholds/limits are agreed upon bilaterally. Both parties measure forecast deviation and exchange this in ongoing dialogue, as outlined in the section on Regular Bilateral Dialogue below.

Download example 1

Download example 2

Remaining shelf life in % – to be exchanged

One of the main goals of this standard is to contribute to reduced food waste. Various factors influence the development of food waste. The industry assumes that increased remaining shelf life through the value chain generally contributes to reduced food waste, and that measuring changes in remaining shelf life will therefore be a relevant indicator. See Plan and prepare for a production

Further definition is under development and will be added to the standard.

Other KPIs – Recommended to be exchanged:

Service Level: Service level is a common KPI in the grocery industry. Refer to the definition in STAND. Of these definitions, the following is recommended: Number of delivered sales units / number of ordered sales units from supplier to wholesaler. Here, sales units refer to D-pack (SKU). Measurement and exchange are agreed upon bilaterally.

8.7 Regular Bilateral Dialogue

The exchange and evaluation of relevant KPIs are part of the bilateral dialogue between the chain/wholesaler and the supplier. The industry has a clear ambition to enhance this dialogue. It is important to establish bilateral platforms where chains and their suppliers can align mutual expectations and results. If such a platform is not already established, both parties may initiate an agreement to set this up, with responsibility lying with the wholesaler. The platform should be established for all suppliers, large and small. Meetings can be physical or digital. The dialogue should be regular, but the frequency will vary based on both parties’ needs. It is assumed that relevant functions with sufficient decision-making authority from both sides will participate.