Requirements for the design of the Distribution Unit (DU) and palletization

The Distribution Unit (DU) is the unit the Stock Keeping Units (SKU) is stacked on / packed in for transport to distributor.

Design of a Standard pallet (Standard pallet and Standard pallet – Low)

A Standard pallet must contain the same product (same GTIN) with a fixed number of Stock Keeping Units (SKU), in a fixed pallet pattern, with equal number of Stock Keeping Units (SKU)on each layer, and where labelling of unique product information on the Distribution Unit (DU) is possible.

The pallet structure shall contain as little excess volume of “air” as possible.

Standard pallet

Maximum pallet height must be 1200 mm incl. pallet. All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers.

Tolerance limit for existing products is 1249 mm.

Standard pallet – Low

Maximum pallet height shall be 600 mm incl. pallet.

Standard pallet – Low is used for low-frequency products and for products with short shelf life.

Principles for the construction of a palletpattern, central in calculation of top load weight, ref Top load labelling system.

When creating a pallet pattern, the following applies:

- A packaged Distribution Unit (DU) must be form stable and handling-friendly

- A Distribution Unit (DU) shall withstand regular transport, handling and storage through the value chain

- For single article Distribution Units (DU), all layers must contain the same number of Stock Keeping Units (SKU), and in a fixed pallet pattern

- Requirements for equal number of Stock Keeping Units (SKU) on each pallet / identical layer from pallet to pallet, with the possibility of variation between the layers

- The pallet should not have overhang

- The Stock Keeping Unit (SKU) should be placed on the pallet as it is exposed in the store

- Do not glue between pallet layers or between Stock Keeping Units (SKU) in the same pallet layer

- If a transport label or product label is attached directly to Stock Keeping Unit (SKU), the label must not overlap between 2 Stock Keeping Units (SKUs), either horizontally or vertically

- All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers.

Types of pallet pattern

When constructing Distribution Units (DU), the Stock Keeping Unit (SKU) must be placed in accordance with a given pallet pattern. These are referred to as bond stacking and column stacking. Pallets can also be built as a combination of bond stacking and column stacking.

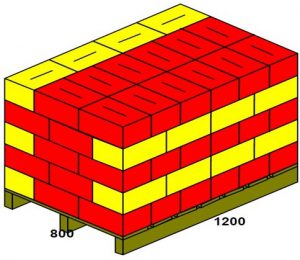

Bond Stacking

Bond Stacking means that the units on every other layer are different, thus locking each other to a greater or lesser extent, but it reduces the compressive strength by approx. 40%.

Example of good pallet utilization and stacking with bond stacking, for good stability.

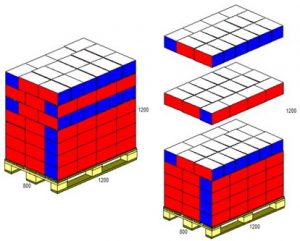

Column Stacking

Column stacking means stacking packages on top of each other without overlapping with other packages. This form of stacking gives maximum strength in terms of pressure load due to that the corners have better roll stiffness than the sides, but the stack gives poor stability without additional use of shrink wrap, strap, ribbon or similar.

Example of column stacking in the lower pallet layers, and bond stacking on the top layer. Combining the different stacking methods achieves good stack strength on the lower layers while the pallet is locked on top.

This is often a good alternative to intermediate pallet sheets.

Use of plastic to secure the pallet through the value chain

- Shrink / stretch film must not be so tight that the packages are deformed

- Shrink / stretch film must be tight around to the pallet

- No tail of plastic must hang loose

- Shrink / stretch film must not cover the fork lift openings on the pallet

- Shrink / stretch film must not be fastened around the pallet blocks

Use of intermediate pallet sheets

Intermediate pallet sheets must be minimized and used only if this is necessary to ensure quality and transportability of the pallet.

Intermediate pallet sheets are preferred if the alternative to this is intermediate cartons, “Ears” on the Stock Keeping Unit (SKU) or use of corner trims.

Where intermediate pallet sheets are used, the following requirements apply:

- The pallet sheet to be used for standard euro pallet should have dimensions of 750 mm * 1150 mm, ie 50 mm less than the length and width of the current load carrier

- The pallet sheet must be of rigid cardboard or corrugated cardboard.

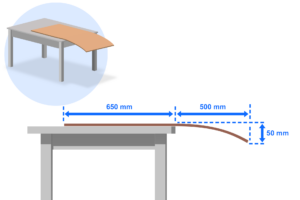

- The stiffness of the pallet sheet must pass the following test: If the short edge of the plate hangs 500 mm from a flat surface (eg a table), the pallet sheet must not bend down more than 50 mm, see illustration below

- No more than one intermediate pallet sheet between each layer

- The intermediate pallet sheet must not be fastened and be flat

- Only a whole intermediate pallet sheet, i.e. without holes or perforations, shall be used

- In case of questions, one is encouraged to contact the packaging supplier

See also Automated storage at distributor – greater understanding of the depalletization process

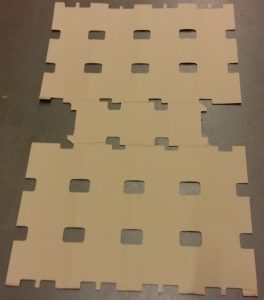

Example of intermediate pallet sheet that does not meet quality requirements. The intermediate pallet sheet is a thin paper and is not suitable for automatic warehouse systems

Example of what happens when using “thin paper” intermediate pallet sheets.

The sheet is hanging down in the robot. It blocks for sensors that check that the layer is separated from the rest of the pallet. The robot will stop, and manual error correction must be carried out before the machine can be restarted.

Example of pallet with intermediate pallet sheets, too big – hanging on outside the pallet.

Is not suitable.

Intermediate pallet sheets with holes. Is not suitable.

| 31.10.2022 | Additional text: “If a transport label or product label is attached directly to Stock Keeping Unit (SKU), the label must not overlap between 2 Stock Keeping Units (SKUs), either horizontally or vertically.” |

| 23.11.2023 | Design of a Standard pallet: All pallets with total height above standard 1200mm with maximum height of 1250 mm to be agreed bilaterally between supplier and their customers. |